Liquid crystal polymers (LCPs) are a class of advanced polymers that retain a highly ordered molecular structure in their solid and liquid crystalline (mesophase) phases. This results in materials and parts with exceptional mechanical strength, temperature resistance, and flame resistance. This article will delve into more detail on the production and application of LCPs.

What is a Liquid-Crystal Polymer?

A liquid crystal polymer maintains a well-organized molecular structure in both its solid and liquid-crystalline phases. Specifically, the transition from order to disorder during the melting of an LCP occurs well above the temperature at which it loses its fully crystallized structure.

This means the material undergoes two distinct phase transitions: first from solid to a liquid crystal (mesophase), and then from mesophase to isotropic liquid. The first phase change takes it from solid to liquid crystal, and the next from liquid crystal to a full liquid. The phase between liquid and crystal is referred to as the mesophase, and the specific molecules that can form a mesophase are termed mesogens. LCPs can be divided into two main categories, namely lyotropic systems and thermotropic systems.

- Lyotropic systems: A liquid crystal that appears with the addition of a solvent.

- Thermotropic systems: A liquid crystal that appears when heated.

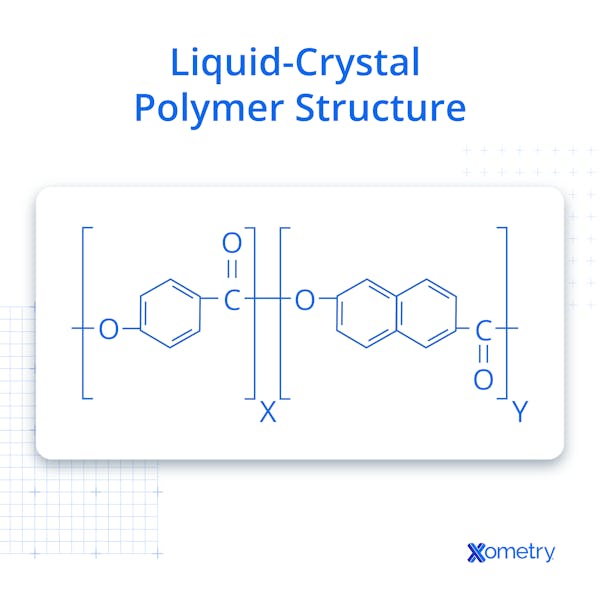

A liquid-crystal polymer is a polymer in which the various mesogen molecules link to form long polymeric chains.

How is Liquid-Crystal Polymer Made?

Most commercial LCPs incorporate p-hydroxybenzoic acid as one of the monomers that build molecular chains through various condensation methods. Monomers such as hydroquinone or 2,6-naphthalene dicarboxylic acid are commonly used alongside p-HBA to adjust processing temperatures and mechanical properties. In addition to these monomers, fillers can be added to the material to further enhance its properties. These fillers can include glass fiber or carbon fiber, enhancing mechanical and thermal properties.

| Property | 30% glass Filled | 40% glass Filled |

|---|---|---|

Property Specific Gravity | 30% glass Filled 1.61 | 40% glass Filled 1.70 |

Property Tensile Strength (MPa) | 30% glass Filled 164 | 40% glass Filled 140 |

Property Elongation (%) | 30% glass Filled 3.0 | 40% glass Filled 1.8 |

Property Flexural Strength (MPa) | 30% glass Filled 163 | 40% glass Filled 198 |

Property Flexural Modulus (MPa) | 30% glass Filled 9237 | 40% glass Filled 8674 |

Property IZOD Notched Impact strength (J/M2) | 30% glass Filled 106 | 40% glass Filled 85 |

Property Rockwell Hardness (R) | 30% glass Filled R77 | 40% glass Filled R79 |

Property Heat Deflection Temp (C) | 30% glass Filled 280 | 40% glass Filled 290 |

Property Molding Shrinkage TD (%) | 30% glass Filled 0.1 to 0.3 | 40% glass Filled 0.08 to 0.25 |

Table 1. Liquid Crystal Polymer Properties

What Are the Uses of Liquid-Crystal Polymers?

Liquid crystal polymers have a wide range of potential uses due to their exceptional physical properties. Some examples are listed below.

- Electrical connectors: LCP plastic is widely used to manufacture high-precision electrical connectors because of its excellent dielectric properties, thermal resistance, and dimensional stability. Conductivity is achieved through metal inserts or conductive paths.

- Vascular catheter reinforcement braiding: Vascular catheters with LCP plastic braiding can be important for patients undergoing MRI scans. Catheters with metallic braiding would interact with the magnetic field generated by the machine.

- Surgical instruments: LCPs are ideal for surgical instruments because they resist degradation from sterilizing radiation methods like gamma or electron beam exposure.

- Cookware coatings: Due to their heat and chemical resistance, LCPs have been explored for use in specialized cookware components, although they are not widely used as conventional non-stick coatings.

What Are the Advantages of Using Liquid-Crystal Polymers?

LCP plastics can be tailored for specific applications by adjusting their molecular structure and incorporating various additives.

- Self-reinforcing: LCP resin molecular chains retain their order when injection molded or extruded. Once cooled, these chains add directional strength to the final parts.

- LCPs can function at continuous temperatures of 240–280°C, with some grades tolerating short-term exposure near 300°C.

- Flame resistant: LCPs are inherently fire resistant.

- Chemical resistance: LCPs are resistant to a wide range of chemicals.

- Dimensional stability: Linear expansion in the direction of flow is extremely low when compared to other plastics.

- Resistance to sterilization radiation: LCPs are not severely damaged when exposed to sterilizing radiation and can therefore be used in medical applications.

What Are the Disadvantages of Using Liquid-Crystal Polymers?

Some typical disadvantages must be understood before considering LCPs for a specific application. Some of these are listed below.

- High cost: LCPs are advanced materials with exceptional properties. As such, they are more expensive than more conventional polymers.

- Anisotropic properties: Properties may vary depending on the direction of the applied load, as polymer chains tend to align longitudinally in the direction of extrusion during processing.

How Does Liquid-Crystal Polymer Affect Human Health?

LCPs are typically safe once processed. The manufacturing of LCP raw material uses dangerous chemicals, but once that is complete, LCPs become inert, much like other polymers. In their solid form, LCPs pose minimal chemical risk to skin or eyes, though contact with hot material or fine particulates can still cause thermal or mechanical irritation. Inhalation of fumes from overheating, combustion, or dust generated during processing may irritate the respiratory tract.

Frequently Asked Questions About Liquid-Crystal Polymer (LCP)

Is Liquid-Crystal Polymer Toxic?

Like other polymers, the combustion products of liquid crystal polymers are very hazardous and toxic. Though most LCPs are flame-resistant, care must be taken to ensure they are not burnt or otherwise ignited.

What is the Difference Between Liquid-Crystal Polymer and Nylon?

Nylon is a semi-crystalline polymer. This should not be confused with a liquid-crystal polymer. Semi-crystalline refers to a partially ordered structure within a polymer. Semi-crystalline polymers have a relatively well-defined melting range, corresponding to the melting of crystalline domains, unlike amorphous polymers, which soften gradually. In contrast, LCPs retain molecular order in their liquid crystalline phase (mesophase), which exists between the solid and fully melted isotropic liquid states. For more information, see our guides on Nylon and What Are Nylon 6 and Nylon 6/12.

What Is the Difference Between Liquid-Crystal Polymer and Thermoplastic?

Liquid crystal polymers represent a specific form of thermoplastic whose properties over a well-defined temperature range are somewhere between those of highly ordered solid crystalline materials and amorphous disordered liquids. Three of the most common forms of liquid crystal polymers include semi-aromatic copolyesters, copolyamides, and polyester-co-amides.

By contrast, the term thermoplastic refers to a class of polymer materials characterized by their ability to retain their chemical properties after repeated cycles of heating and cooling. Unlike thermosets, whose properties are permanently changed once the material has been heated and cooled, thermoplastics can be repeatedly put through cycles of heating and cooling. This capability enables thermoplastics to be recycled and the material to be repurposed. They will soften when heated and then harden once cooled. Thermosets, once cooled after initially being heated, undergo a permanent chemical change and will not remelt if exposed to heat, and therefore, are not recyclable.

Liquid crystal polymer is one specific type of the broad class of polymers known as thermoplastics.

Summary

This article summarized the properties, uses, advantages, limitations, and toxicity of liquid crystal polymer.

About Xometry

Xometry offers plastic injection molding, 3D printing, and other manufacturing services for all of your project needs. Visit our website to learn more or to request a free, no-obligation quote for your part manufacturing requirements.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.