Nylon is the designation for a family of synthetic polymers composed of polyamides (repeating units linked by amide links). Nylon is a silk-like thermoplastic, usually made from petroleum, that can be melt-processed into fibers, films, or shapes. In addition, nylon polymers can be mixed with various additives to achieve different property variations.

This article explains what nylon is, the purposes of using it, the history of nylon, the most popular nylon products, its properties, how it is manufactured, its disadvantages, and whether or not it is harmful. This article also looks at some of the different types of nylon: nylon 1/6, nylon 4/6, nylon 510, nylon 6, and nylon 6/6.

What Is Nylon?

Nylon is also known as Polyamide or PA. Nylon plastic is an engineering-grade thermoplastic. It is used in consumer goods, automotive, electronics, and more.

Even though there are different polyamides, they are generally characterized by good heat resistance, chemical resistance, and electrical insulating properties resulting from their partially crystalline structure and strong hydrogen bonding between polymer chains. This material is durable, versatile, and exhibits high tensile strength and fatigue resistance in terms of mechanical properties. It also possesses excellent abrasion and friction behavior. Nylon can be made flame-retardant through the addition of specific additives, but unmodified nylon is flammable and melts when burning. Its melting point varies by grade, but the most commonly used grade, nylon 6, has a melting temperature of 428 °F (220 °C), while nylon 6/6 melts at approximately 509 °F (265 °C).

What Is the Purpose of Using Nylon?

The purpose of using nylon is to create a high-quality yet light product. What is nylon used for? It is used for fabric for shirts, foundation garments, lingerie, raincoats, swimwear, underwear, and cycling wear.

Nylon is also used in construction and industrial applications, where it can be molded into components such as sheets, tubes, pipes, screws, bolts, safety nets, and plumbing fittings. It can be melted into filaments for 3D printing and other machining. In fishing nets, its low weight, tensile strength, and abrasion resistance allow it to handle heavy loads without breaking.

Nylon’s durability, low weight, and resistance to heat and chemicals make it suitable for machine parts such as screws, nuts, bolts, appliance bearings, and sliding or rotating mechanisms. In electronics, it is used for circuit boards, electrical cord insulation, and components requiring a low coefficient of friction.

When Was the First Time Nylon Was Used?

Nylon was first introduced to the public for women's stockings at the 1939 New York World's Fair, although it had been developed several years earlier. Nylon's use increased dramatically during World War II when the need for fabrics increased markedly. Nylon was used to replace silk in parachutes and other military textiles during World War II. It was also used to make tires, ropes, tents, ponchos, and other military supplies.

At the beginning of WWII, cotton made up more than 80% of all fibers used and manufactured, and wool fibers accounted for most of the rest. By August 1945, synthetic fibers had taken a market share of 25% at the expense of cotton. After the war, nylon parachute material was sometimes repurposed to make dresses because of nylon and silk shortages.

What Are the Properties of Nylon?

Nylon is lustrous, which means it has a shine. The plastic can be very lustrous, semi-lustrous, or dull, depending on its desired use. This is one reason it is often used as a fabric.

Nylon’s elasticity is due to its molecular structure, which includes amorphous regions that can stretch and recover. Above its melting temperature, it becomes a viscous fluid, but elasticity in practical use comes from the behavior of the solid-state amorphous regions. Below its melting temperature, nylon has amorphous regions that alternate with regions that are lamellar crystals. The amorphous regions contribute elasticity to the plastic.

Nylon’s high tensile strength and durability make it suitable for applications that must withstand impacts, oils, and many chemicals. Even in thin fibers, it remains strong and wear-resistant. Because it can mold into any shape, nylon is useful for products that require flexibility. Its flexibility comes from its natural elasticity. Nylon dries quickly, making it suitable for fabrics where moisture-wicking is important, and it dries faster than many natural fibers because it absorbs less water, although it is not fully hydrophobic.

For more information, see our guide on the Properties of Nylon.

Why is Nylon So Widely Used?

Nylon is so widely used because it is an extremely versatile synthetic plastic. Polyamide nylon has various advantages that make it ideal for many applications, including household items and clothing.

For more information, see our guide on the 4 Uses of Nylon.

What Are the Various Types of Nylon?

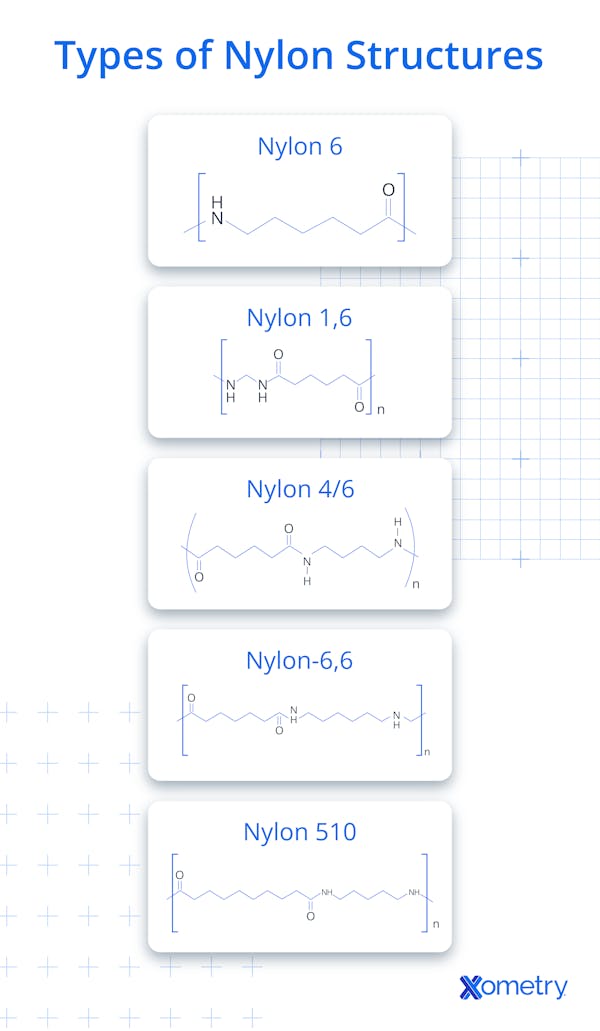

The various types of nylon are nylon 1/6, nylon 4/6, nylon 510, nylon 6, and nylon 6/6.

Some nylons can be synthesized from dinitriles using acid catalysis. For example, nylon 1/6 can be produced from hexamethylenediamine and adipic acid derivatives, though laboratory syntheses may also involve adiponitrile, formaldehyde, and water. It has a high moisture absorbance because of the polymer's significant density of amide residues. Nylon 1/6 is not typically used for fabrics.

Nylon 4/6 was developed to have a higher heat resistance and faster crystallization rate than nylon 6 and nylon 6/6, making it suitable for high-temperature automotive and industrial parts. The advantages of nylon 4/6 include a higher heat distortion temperature than nylon 6 or nylon 6/6, higher crystallinity that leads to better chemical resistance, particularly to acidic salts, and short cycle times. The disadvantages of nylon 4/6 are that it has similar moisture absorption to nylon 6/6, but the dimensional increase is minor, and it has a high processing temperature.

Nylon 510 is made from pentamethylene diamine and sebacic acid and was included in the original DuPont patents alongside nylon 6/6. It has superior properties but is more expensive to produce. Because its production costs ultimately prohibited the mass production of this polymer for fabric purposes, the applications of nylon 510 are used in industrial and scientific applications. Its advantages include its strength and durability. Its disadvantages include the high production cost.

Nylon 6 fibers are tough, possessing high tensile strength, elasticity, and luster. The fibers can absorb up to 2.4% of water, although this lowers tensile strength. Nylon 6 is generally white as a synthetic fiber, but can be dyed in a solution bath before production for different color results. The tenacity of nylon 6 fibers is typically 6–8.5 g/denier, and its density is about 1.14 g/cm³. Its melting point is about 215 °C (419 °F), and it can typically withstand continuous use up to around 150 °C (302 °F).

The advantages of nylon 6 are that its fibers are wrinkleproof and highly resistant to abrasion and chemicals such as acids and alkalis. A disadvantage is that it can be more challenging to process than some other nylons because of its relatively low melt viscosity.

Nylon 6/6 generally has a higher degree of crystallinity than nylon 6 due to its more symmetrical molecular structure. It is also referred to as polyamide 66 or PA 66 and has improved mechanical properties due to its more ordered molecular structure. Nylon 66 for machining has improved temperature resistance and lower rates of water absorption when compared to standard nylon 6. The applications of nylon 6/6 include wear pads, guide wheels, and slide bearings.

The advantages of nylon 6/6 are that the yield strength is higher than nylon 6 and nylon 6/10. It has high strength, toughness, rigidity, and a low coefficient of friction in a wide temperature range. In addition, it is oil-resistant and resistant to chemical reagents and solvents.

For more information, see our guide on the 5 Types of Nylon.

What Are the Disadvantages of Using Nylon?

The disadvantages of using nylon are that it absorbs water, which results in lower mechanical properties, has low resistance to strong bases and acids, and has a high percentage of shrinkage in cast applications.

Although nylon can self-extinguish under certain conditions, it is flammable and melts when burning. Nylon also lacks UV resistance and becomes yellow irrespective of color, becoming fragile and rapidly deteriorating. It is also not biodegradable.

Frequently Asked Questions About Nylon

How Is Nylon Manufactured?

Nylon 6/6 is produced by reacting hexamethylenediamine with adipic acid in a condensation polymerization process. The nylon composition is then extruded through a spinneret with dozens of tiny holes. Upon extrusion through the spinneret, nylon filaments are cooled (often by air or water) to solidify before being wound onto bobbins.

Nylon fibers are then stretched to increase their strength and elasticity. Nylon is then wound onto another spool in a "drawing" process that makes the polymer molecules arranged in a parallel structure. After the drawing process, the resulting fibers are ready to be spun into fabric or used for other purposes.

Is It Harmful To Use Nylon?

No, nylon is not harmful to use. Nylon polymers are generally stable and are not considered harmful to most people in normal use, making the fabric safe for consumer applications. However, some people who are sensitive to materials made from petroleum may react to nylon. Nylon may be considered harmful to the environment because it is not readily biodegradable and can contribute to microplastic pollution.

Summary

This article provided a summary of the uses, properties, types, and advantages of nylon as a material for use in product and part fabrication.

Xometry offers injection molding services for all of your prototyping and production needs. Visit our website to learn more and to request a free, no-obligation quote using our Instant Quote Engine.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.