A collimated beam is a stream of light particles or other electromagnetic radiation that travels parallel to each other, without spreading out. The beam is focused in a single direction, and the energy is evenly distributed along its path. This unique property makes collimated beams useful in various fields, including scientific research, engineering, and medical applications. In this article, we will delve deeper into the definition of a collimated beam, how it works, and its applications.

What Is a Collimated Beam?

A collimated beam refers to a beam of light or other electromagnetic radiation that is parallel and uniform, with minimal divergence or spreading as it travels. It is a beam of light that approximately maintains its size and shape over long distances. The term "collimated" comes from "collimate," meaning to make light rays parallel. Collimated beams are often achieved through the use of lenses or mirrors that help align the light rays to travel in parallel. In an ideal scenario, a perfectly collimated beam would not disperse or diverge with distance. However, due to the phenomenon of diffraction, it is not possible to achieve a beam with absolutely no spreading. Nonetheless, collimated beams maintain a high degree of parallelism, making them useful in applications where minimal spreading is desired, such as laser technology, optics, imaging systems, and scientific research. Collimated beams are also used industrially in processes such as welding, cutting, and engraving. In some laser-based 3D printing methods, collimated beams may also be involved.

What Is the Other Term for Collimated Beam?

Other terms that have the same general meaning as “collimated beam” include "parallel beam" or “collimated light.”

What Is the Importance of Collimated Beams in Laser Cutting?

The collimated beam is important in laser cutting because it allows for precise and accurate cutting of materials. When the laser beam is collimated, it maintains its intensity over longer distances before being focused for cutting. It can then be focused through a focusing lens, resulting in sharp and well-defined cuts. This enables the laser cutter to produce intricate designs with high-quality finishes.

Furthermore, the collimated beam provides efficiency in the cutting process. By maintaining parallel rays, the laser energy remains concentrated, maximizing the cutting power and allowing for faster cutting speeds. The collimated beam also enables the laser cutter to propagate the beam over longer distances without significant beam spreading or loss of cutting performance. Optical systems using collimated beams allow adjustments to focal length and spot size, making them compatible with a wide range of materials. This versatility allows for the efficient cutting of various materials, including metals, plastics, fabrics, and composites. For more information, see our What is Laser Cutting Used For guide.

What Is the Purpose of a Collimated Beam?

The purpose of a collimated beam is to deliver light or radiation that travels in nearly parallel paths with minimal divergence. This is achieved by passing the beam of light through a collimator — a device that helps align and straighten the path of the beam. Collimated beams have several practical applications, including in scientific research, laser technology, medical imaging, and industrial processes like laser cutting and welding.

How Does Collimation Work?

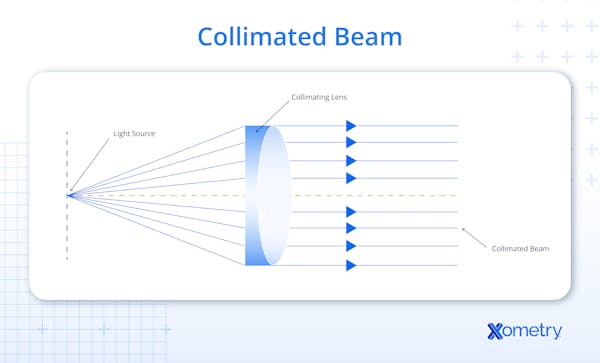

Collimation works by directing light or other radiation through a lens or a set of lenses to make the rays from the source parallel to each other. When the light is collimated, the beam will remain narrow and approximately parallel over long distances. The collimation process begins with the light source, which emits light rays in various directions. These rays are directed through a collimator lens or a series of lenses, which refract and direct the light so that the rays become parallel.

How Is a Collimated Beam Produced Using a Lens?

A collimated beam can be produced using a lens by placing the light source at the focal point of a convex lens. The light rays emanating from the source are diverging, and the convex lens refracts the light rays into a parallel path. At this point, the emerging light rays form a collimated beam of parallel rays.

Another method is to use a set of lenses, typically called a collimator lens system, to create a collimated beam. The light source is placed at one end of the system, and the lenses are arranged to refract and direct the light into a parallel beam. This method is commonly used in laser diodes, telescopes, and other optical devices that require a collimated beam.

How Is a Collimated Beam Produced in a Laser Cutter?

In a laser cutter, a collimated beam is typically produced by passing the laser beam through a series of lenses or mirrors. These mirrors align and redirect the beam to maintain a parallel and uniform diameter before focusing. The first lens is used to collimate a diverging laser beam and create a parallel beam. This collimated beam is then directed towards the cutting head, where it is focused again by another lens or mirror to a small spot size for cutting. This focusing component is often referred to as a focuser.

The focuser allows for adjustment of the beam's spot size at a specific working distance. It can either shrink or magnify the spot size to achieve the desired beam characteristics for a particular application.

What Are Some Typical Applications of Collimated Beams?

Collimated beams have a wide range of applications, including:

1. Laser Technology

Collimated beams are fundamental in laser technology, enabling precise cutting, welding, drilling, and marking by maintaining beam shape and intensity over long distances. They are used for laser beam generation, beam propagation, laser beam manipulation, and optics and beam delivery.

2. Optical Communication

In optical communication, collimated beams are primarily used in free-space optical links and for coupling light into optical fibers, rather than for transmitting data through the fibers themselves. Optical communication relies on the transmission of information through the use of light signals, typically in the form of laser beams. The collimated beam's ability to maintain its diameter allows for efficient data transmission over long distances without significant signal loss. Collimated beams play a crucial role in optical communication systems, particularly in fiber optic networks. They are used in fiber optic transmission, fiber optic amplification, free-space optical communication, and optical alignment.

3. Medical Imaging (CT and PET Scans)

Collimated beams play a crucial role in medical imaging, particularly in computed tomography (CT) and positron emission tomography (PET) scans. In CT scans, collimated beams help to produce accurate and detailed images of the human body. In CT imaging, a collimated X-ray beam is used to acquire multiple cross-sectional images (slices) of the body, which are then reconstructed to create a three-dimensional representation. Collimated beams are utilized in CT scans for consistent radiation, improved spatial resolution, artifact reduction, and dose optimization.

Collimators are used in SPECT imaging systems and sometimes in hybrid PET/SPECT systems. However, traditional PET scanners rely on coincidence detection and typically do not use mechanical collimators. Collimators are utilized in PET scans for sensitivity enhancement, spatial resolution improvement, and background reduction.

4. Astronomy (Telescopes)

Collimated beams help maintain optical alignment and image clarity in astronomical systems such as reflective and refractive telescopes, imaging setups, and calibration devices.

5. Industrial Inspection

Collimated laser beams are used in some industrial inspection systems for precise dimensional measurement and laser profiling. However, non-destructive testing (NDT) typically uses X-rays, ultrasound, or eddy currents rather than collimated light.

6. Spectroscopy

Collimated beams are extensively used in spectroscopy to accurately analyze the interaction of light with matter and obtain valuable information about the properties of substances. Some examples of its uses are sample illumination, beam alignment, measuring of absorption and transmission properties of samples, and in the study of emission and fluorescence properties of samples.

7. Microscopy

In microscopy, collimated beams provide a stable light source that enables high-resolution imaging with minimal distortion. Examples of the uses of collimated beams in microscopy are illumination, laser scanning microscopy, and optical tweezers.

How Does the Quality of a Collimated Beam Affect the Performance of a Laser Cutter?

The quality of the collimated laser beam plays a significant role in determining the performance of a laser cutter. A high-quality collimated beam has several advantages, including improved cutting speed, precision, and accuracy. A laser beam can be precise (with low variability) but not accurate (if it consistently measures values away from the true value). Conversely, a laser beam can be accurate (with measurements close to the true value) but not precise (if the measurements are widely scattered or inconsistent). Ideally, a laser beam should exhibit both high precision and high accuracy for reliable and meaningful measurements.

A well-collimated beam minimizes the beam divergence, ensuring that the laser ray does not spread out as it travels. This results in a smaller focal spot size, which allows for the precise cutting of materials with high accuracy. Additionally, a well-collimated beam reduces the occurrence of unwanted reflections or refractions, leading to clean cuts and reduced material damage.

How Is a Collimated Beam Used to Achieve Precise Cuts in Laser Cutting?

The collimated laser beam is focused into a small spot on the material to be laser cut, resulting in a very narrow, precise cut. The beam is focused by a lens or a series of lenses to produce a high-intensity spot with a diameter as small as a few micrometers. This high-intensity spot vaporizes or melts the material at the point of contact, allowing for precise cuts.

What is the Role of Collimated Beams in Gas Lasers?

Gas lasers produce beams that are naturally low-divergence due to the resonator design. External collimating optics, such as a collimating lens, may be used to further shape the output into a more parallel beam. Gas lasers inherently generate low-divergence beams, which can be further collimated using external optics for specific applications. To learn more, see our full guide on gas lasers.

What Function Does the Collimated Beam Serve in Fiber Lasers?

In a fiber laser, the collimated beam is important for transmitting the laser light through the fiber optic cable. The fiber laser works by amplifying the light signal passing through the fiber optic cable, which produces a high-power beam that can be used for cutting, welding, and other applications. The light signal in a fiber laser is guided through the fiber by total internal reflection, not by collimation. Collimated beams are used at the input and output ends for coupling and beam shaping. Without a collimated beam, the light signal would diverge as it travels through the fiber optic cable, leading to a weaker and less precise laser beam. For more information, see our guide on What is a Fiber Laser.

Is a Collimated Beam Also Used in Laser Welding?

Yes, collimated beams are also used in laser welding. In laser welding, a high-power laser beam is focused onto the workpiece to melt the materials to be joined and create a weld. Collimated beams are used to ensure that the laser beam maintains its focus over a longer distance, which is important for welding applications that require a greater depth of field. This allows for precise and accurate welding with minimal distortion or damage to the surrounding material.

What Are the Benefits of Using Collimated Beams?

There are several benefits of using a collimated beam, including:

- Increased Precision: The beam's parallel nature ensures that the energy is concentrated in a small area through the focusing lens, resulting in higher precision and accuracy in devices like laser cutters. A collimator aligns the beam rays to travel in the same direction, helping preserve the beam shape and intensity for accurate focusing. However, it does not prevent all energy loss. It is a way to avoid leaking energy.

- Reduced Divergence: The beam maintains its size over longer distances, making it ideal for long-distance applications.

- Reduced Energy Loss: Collimation helps reduce beam divergence and maintains energy concentration over distance, though some loss still occurs due to absorption, scattering, or imperfect optics. This results in greater energy efficiency and a longer operating life for the laser.

- Versatility: Collimated beams can be used in a wide range of applications, including laser cutting, welding, drilling, and marking, as well as medical, scientific, and industrial applications. Collimated beams can also be used in various laser types, including gas lasers, fiber lasers, and solid-state lasers.

- Reduced Beam Distortion: Collimated beams can help reduce beam distortion, which can occur due to atmospheric turbulence or other environmental factors. This results in better beam quality and more reliable results.

What Are the Limitations of Using Collimated Beams?

Here are some limitations of using collimated beams:

- Complexity: Generating a collimated beam of electromagnetic radiation can be a complex process that requires precise alignment of optical components, which can make it difficult to implement in certain applications.

- Cost: Technology that makes use of collimated beams of electromagnetic energy, whether light, electrons, or x-rays, is sophisticated and expensive. This may limit access to the instruments or equipment in some cases, but in many cases, no better alternative exists, and the advantages of such technology outweigh the costs.

- Beam Quality: While collimated beams have high beam quality, it can be difficult to maintain this quality over long distances or when passing through different mediums, which can result in beam degradation.

Frequently Asked Questions About Collimated Beams

Are Collimated Beams Susceptible to Diffraction?

Yes, collimated beams are susceptible to diffraction. Diffraction refers to the bending or spreading of waves when they encounter an obstacle or a slit that is comparable in size to their wavelength. Even though they are highly parallel and have minimal divergence, collimated beams can still experience diffraction when they pass through small apertures or lenses. The amount of diffraction that occurs depends on the wavelength of the radiation and the size of the aperture or lens. Diffraction causes even collimated beams to spread slightly over distance, limiting how perfectly they can remain parallel. This spreading is an inherent physical limit, not a flaw in the beam.

Are Collimated Beams Affected by Atmospheric Turbulence?

Yes, collimated beams can be affected by atmospheric turbulence. As the beam travels through the atmosphere, it can encounter changes in refractive index caused by variations in temperature, pressure, and humidity. These changes in refractive index cause the beam to bend or scatter, leading to distortion or degradation of the beam's collimation. The effect is local refraction variations, which lead to beam wander, distortion, and loss of coherence in the beam path. This effect is caused by atmospheric turbulence. This can significantly limit the range, focus stability, and signal integrity in laser-based remote sensing, tracking, and free-space optical communication systems. However, some techniques, such as adaptive optics, can be used to mitigate the effects of atmospheric turbulence on collimated beams.

Can Collimated Beams Be Produced With Zero Divergence?

No, collimated beams cannot be produced with zero divergence. The defining characteristic of a collimated beam is that its rays are parallel and do not diverge significantly. If a beam had infinite divergence, the rays would spread out in all directions and no longer remain parallel.

Summary

This article presented collimated beams, explained what they are, and discussed its various applications. To learn more about collimated beams, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.