Learn more about this process and the different materials that can be used.

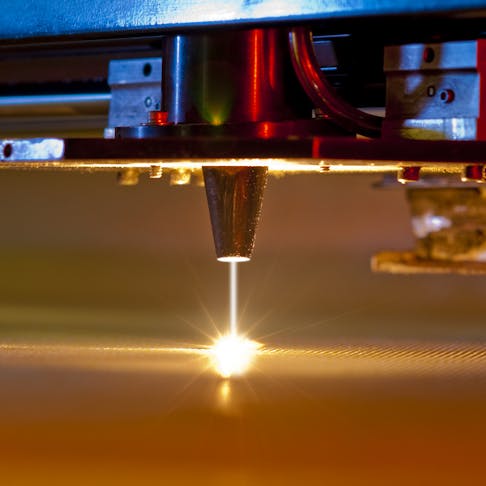

Laser fusion cutting refers to a laser cutting technique used to cut metals by first melting them and then blowing out the molten material using a high-pressure inert gas. This process is used primarily on thin sheets and can prevent oxidation from forming on the cut edges.

Unlike laser flame cutting, all the energy in laser fusion cutting is provided by the laser, making these laser cutting machines less energy efficient. This article will describe the laser fusion cutting process, its advantages, disadvantages, and applications.

What Is Laser Fusion Cutting?

Laser fusion cutting is one method of laser cutting metal that is used in both CO2 and fiber laser cutters. This process relies solely on the energy provided by the laser to successfully cut through the metal. Unlike laser flame cutting, this process does not make use of oxygen to initiate an oxidation process that reduces the energy required for the laser. This technique is valued for its clean finish, which reduces or eliminates the need for post-processing by preventing edge oxidation.

How Does Laser Fusion Cutting Work?

Laser fusion cutting can be performed with a CO2 laser as well as a fiber laser, provided the power levels are high enough for cutting metal. The laser begins by heating the metal to a molten state. Once this is achieved, a high-pressure stream of an inert gas like nitrogen or argon is blown out of the cutting head into the molten material, which is then ejected out of the bottom of the plate. In some cases, oxygen can be used during the initial piercing phase to help cut through the plate, and then inert gas is used. As the beam moves through the material, it continues to melt the metal, and the inert gas ejects the molten material from the cut. The inert gas cools and shields the cut edge, preventing oxidation during and after cutting.

What Are the Advantages of Laser Fusion Cutting?

Laser fusion cutting is a popular laser cutting technique due to a range of advantages as listed below:

- Oxide-Free Cut Edge: The inert gas protects the hot cut edge from reacting with atmospheric oxygen and prevents any oxidation from occurring. This is especially effective for stainless steel parts, which form an oxide layer on the cut edges that must be removed using pickling and passivation processes.

- Localized Heating: The focused laser beam provides localized heating, while the inert gas helps eject molten metal and shields the cut from oxidation. This reduces heat transfer to surrounding areas and helps minimize thermal warping. As such, thin sheets can be cut into intricate patterns without any warping.

- Lower Energy Requirements Compared to Vaporization: Vaporization laser cutting techniques require that the material be heated to the point of vaporization. This requires significantly more energy than fusion laser cutting, which only needs to heat the material into liquid form.

- High-Speed Cutting of Thin Sheets: Fusion laser cutting is a high-speed production technology, especially with thin sheets. The cooling effect of the inert gas means that more energy can be utilized without the risk of warping thin sheets.

What Are the Disadvantages of Laser Fusion Cutting?

Despite the many advantages of laser fusion cutting, there are some disadvantages as listed below:

- High Energy Compared to Laser Flame Cutting: Laser fusion cutting requires more laser energy than flame cutting, which uses oxygen to initiate exothermic oxidation that aids in cutting. Fusion cutting relies entirely on the laser beam to melt the material, making it more energy-intensive.

- Thin Sheet Metal Only: Due to the high energy requirements, only thin sheets are recommended for laser fusion cutting. Thicker sheets require excessive energy to melt through the plate, and in some cases, the melt will never reach through the entire width of the plate. This can be mitigated to an extent by using oxygen for the initial piercing action.

- Striation Formation: Striations are formed due to oscillations in the melt front and fluctuations in laser power or gas flow, resulting in visible lines on the cut edge that reduce surface quality and are undesirable.

For more information, see our guide on the Advantages and Disadvantages of Laser Cutting.

How Does Laser Fusion Cutting Differ From Other Types of Cutting?

Laser fusion cutting differs primarily in the type of cut edge that is left after cutting, i.e., unoxidized. Laser flame cutting typically produces oxidized cut edges due to the use of oxygen, while vaporization cutting may also result in oxidation depending on the assist gas and material used. This oxidation must be removed for aesthetic purposes as well as to prepare the edge for subsequent welding. Fusion cutting generally requires more energy than flame cutting due to the absence of exothermic oxidation. However, energy requirements compared to vaporization cutting depend on the material and thickness being processed. Laser fusion cutting is particularly useful for cutting thin stainless steel sheets due to the elimination of oxidation and the ability to localize heat in the cut zone rather than transferring it to the rest of the plate, which can cause warping.

What Are Some Common Applications for Laser Fusion Cutting?

Laser fusion cutting is ideal for the high-volume processing of stainless sheet metal components. Some additional applications are listed below:

- Stainless steel piping

- Finely detailed sheet metal cutouts

- Precision cutting of thin metal components for medical or aerospace applications

- Cutting titanium sheeting

- Cutting magnesium alloy sheeting

What Materials Can Be Used With Laser Fusion Cutting?

Laser fusion cutting is especially effective with materials that are sensitive to oxidation. Examples are listed below:

- Stainless Steel Sheet: Sheets up to approximately 10–15 mm can be cut using laser fusion cutting, although best results are typically achieved with thinner sections.

- Thin Stainless Steel Tubing: Laser cutters equipped with a fourth axis can be used to cut thin tubing.

- Alloyed Steel: Alloyed steel sheeting can be readily cut without the development of oxidation on the cut surface, meaning components can be welded without additional surface preparation.

- Aluminum: Aluminum sheeting can be cut using laser fusion to avoid oxide buildup and discoloration, which can interfere with subsequent welding or finishing steps like anodizing.

- Magnesium Alloys: When oxidized, magnesium alloys produce a high-energy reaction. As such, they must be cut in an inert atmosphere.

- Titanium Alloys: Titanium is readily oxidized at high temperatures. As such, laser fusion cutting is a good option for cutting this material as it protects the cut edge from oxidation.

What Is the Procedure for Laser Fusion Cutting?

The laser fusion cutting process is very similar to other laser cutting processes with a few key differences as described below:

- The sheet is placed on the cutting bed and accurately positioned.

- Once in position, the laser head moves to the start point and begins heating the material until it has reached a molten state throughout the thickness of the plate.

- Once the molten state has been achieved, a high-pressure stream of inert gas (typically nitrogen), often ranging from 10 to 20 bar depending on material and thickness, is directed at the molten metal to blow it out of the cut.

- The laser head moves along the cut path while continuously heating the material to its molten point. The inert gas continues to blow the molten material from the cut.

- During cutting, the inert gas shields the molten edge from atmospheric oxygen, preventing oxidation. This role is conceptually similar to shielding gas in TIG welding, although applied differently.

- The focused laser beam provides localized heating, while the inert gas assists in removing molten metal and slightly cooling the cut zone. This combination helps minimize heat transfer and warping.

- Once the parts are removed, they do not require mechanical or chemical post-processing to remove oxidation from the cut edge and can be welded.

Frequently Asked Questions About Laser Fusion Cutting

What Are Laser Fusion Cutting Machines?

Laser fusion cutting machines are designed to cut thin metal sheeting while minimizing warping and preventing oxidation at the cut edges. This allows parts to be welded without additional surface treatment.

What Gas Is Used in Laser Fusion Cutting?

Inert gases like nitrogen or argon are often used in laser fusion cutting, with nitrogen being the most commonly used. This inert gas is used so that the edges are not oxidized during cutting by displacing atmospheric oxygen from the cut area. In addition, some laser cutting machines also use oxygen to assist in initial piercing.

Is Laser Fusion Cutting Faster Than Other Types of Laser Cutting?

Yes, for thin sheets (especially stainless steel), fusion laser cutting is faster than vaporization cutting and often faster than flame cutting. However, laser flame cutting may be faster for thicker mild steel because of the additional heat from oxidation. Because the inert gas cools the cut zone, fusion cutting can operate at higher speeds than other methods that risk overheating and warping the material. However, with thicker plates, laser fusion cutting is no longer comparatively fast.

Summary

This article presented laser fusion cutting, explained what it is, and discussed the process and materials used for it. To learn more about laser fusion cutting, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.