The Complete Xometry Production Guide

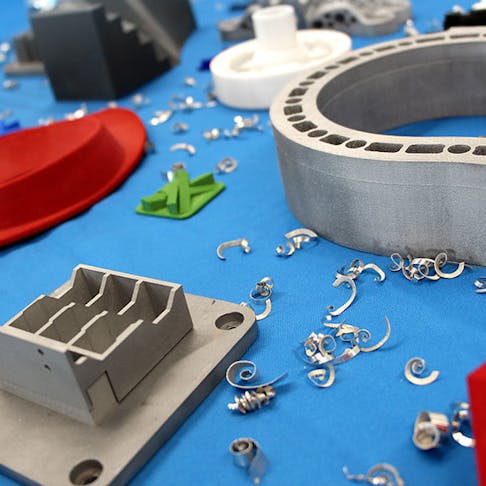

Choosing the Right Process for Your Custom Parts

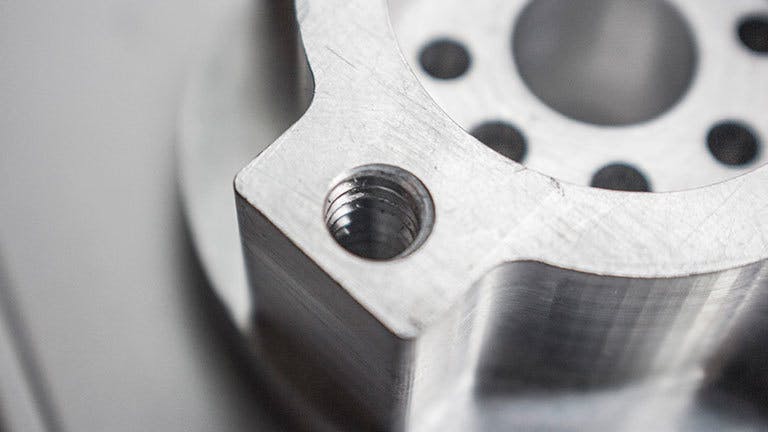

Xometry's Online CNC Machining Service

Xometry is the industry leader in custom, quick-turn CNC machining services for rapid prototyping and production parts. Our online Instant Quoting Engine gives you a CNC machining quote within seconds. Then we make your machined metal or plastic parts and get them to your door in as few as 2 days. We inspect the parts and manage your order.

Our massive partner network means that whatever your part, we have a shop and a machine that can make it. We integrate seamlessly with over 3,000 vetted manufacturing partners in the U.S. including ITAR qualified facilities and we are ISO 9001:2015 and AS9100D certified.

With such a high volume of qualified shops and over 40 certified materials available, using Xometry takes the guesswork out of CNC part sourcing. Our partners support the latest in CNC machining and turning processes, can support a high level of part complexity, and provide exceptional surface finishes. We can also machine and inspect to any 2D drawing, always ensuring you have the CNC machined parts you need, at-quality and on time.

The Benefits of CNC Machining

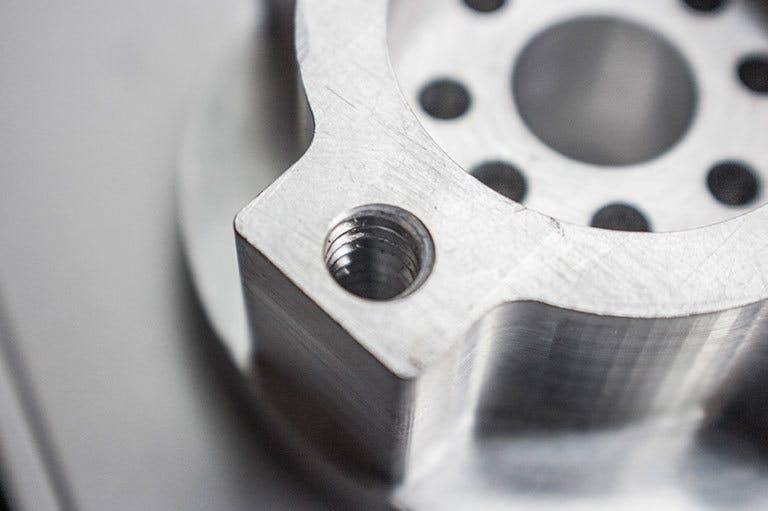

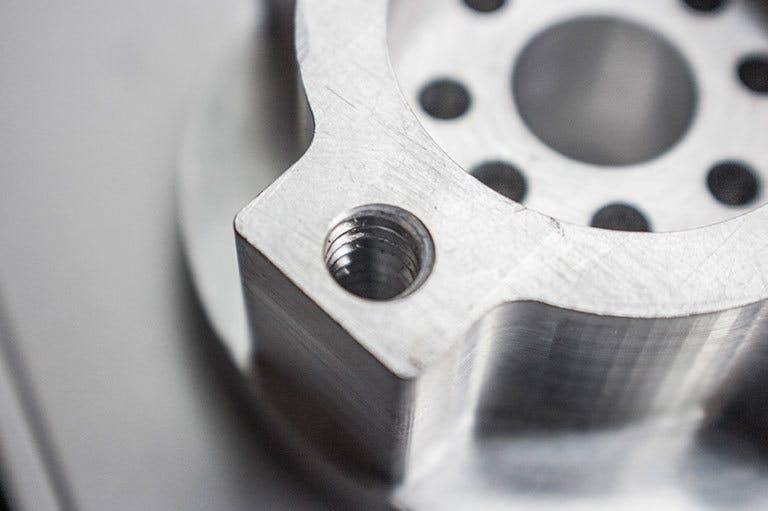

Extreme Precision and High Quality

CNC Machining is one of the fastest, most accurate methods available to build market-quality parts for almost any application. CNC removes material using high speed, precision machines that are programmed to use a wide variety of cutting tools to create the final design.

Fast Delivery

Xometry can machine parts in most common metals and plastics in as little as 6 business days. Our standard lead time for most orders is 10 business days.

Economical With Minimal Setup

We offer 5-axis CNC Machining to produce appropriate parts quickly and with minimal setups.

The Trade-Offs With CNC Machining

Given the cost of material and setup, CNC Machining can be more expensive for smaller quantities of parts. Certain features, such as those that cannot be reached by the milling tool, cannot be produced. Sharp interior corners must have a radius of at least 0.0156”, and square interior corners will have a corner radius of 1/8 times the depth of the pocket applied.

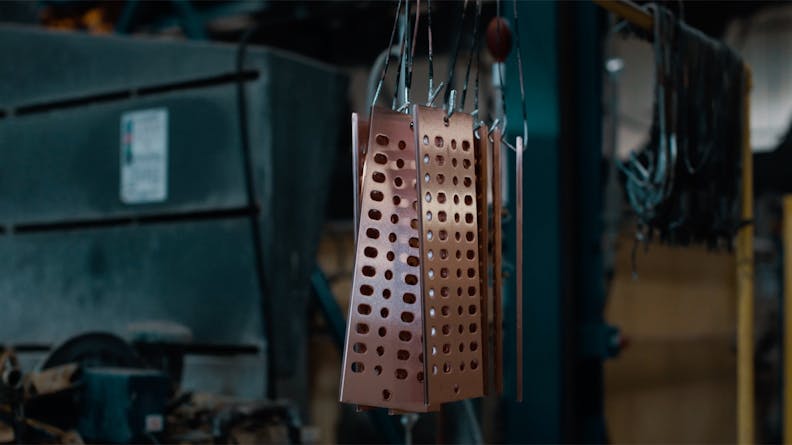

Xometry's Sheet Metal Fabrication Services

Sheet metal fabrication is the process of forming parts from a metal sheet. 3D CAD files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part. Typical forming tools are brakes, punches, and dies which can form angular bends and features.

Installing inserts, such as PEM inserts, is standard practice along with welding and finishing services. Sheet metal parts are known for their durability, which makes them great for end-use applications (e.g. chassis). Parts used for low volume prototypes and high volume production runs are most cost-effective due to large initial setup and material costs.

Our custom sheet metal services offer a cost-effective and on-demand solution for your manufacturing needs. Fabrication services range from low-volume prototype to high-volume production runs with significant cost savings.

The Benefits of Sheet Metal

Production Quality

We currently offer sheet metal fabrication services including bending, punching, and cutting many different metals to form your part for either low to high volume production runs. Parts are well known for their durability and precision, which makes them perfect for end-use.

Durable, Uniform Thickness

Sheet metal fabrication produces thin-walled, metal parts that can’t be produced with CNC Machining. Chassis, enclosures, and brackets are perfect for Sheet Metal Fabrication because they maintain a uniform thickness and need to be rigid and durable.

Quantity Discounts

As quantity increases, price per part drastically decreases due to the fact that parts are able to be patterned on the same stock of material.

The Trade-Offs With Sheet Metal

Sheet metal may be expensive for lower quantities of parts due to tooling, setup and material costs. Sheet metal fabrication cannot be used for parts with non-uniform or large wall thicknesses. Sharp interior corners are incompatible with this method, as the sheets are bent with machinery that has rounded corners.

Xometry's SLA 3D Printing Services

Stereolithography (SLA) is a powerful 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

Stereolithography is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. Stereolithography 3D printing is a highly-versatile platform for making custom parts in prototype and production settings, often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, offering up to a 29" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

The Benefits of SLA 3D Printing

Smooth Moves

SLA parts are printed with almost glassy finish—smoother than other 3D Printing processes—due to their UV curing process. (Note: matte finish is also available.)

Physical Snapshots

Combining high resolution prints with speed and versatility, parts printed in SLA allow product developers to see their designs come to life quickly and cost-effectively throughout the iterative process.

Detail-Oriented

SLA's precision and fidelity allows for highly detailed features, such as embossing, that are not always possible with other 3D Printing processes.

The Trade-Offs With SLA 3D Printing

Long and broad are subject to uneven curing, which can lead to warping. They are also more susceptible to distortion caused by heat and moisture which can happen during post-processing or shipping. As with most 3D Printing processes, there is a risk of especially small features not resolving. Be sure to meet the minimum suggested dimensions to avoid resolution errors.

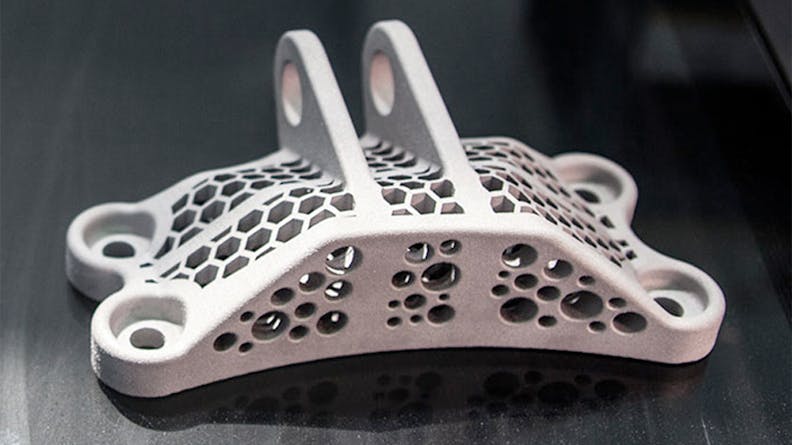

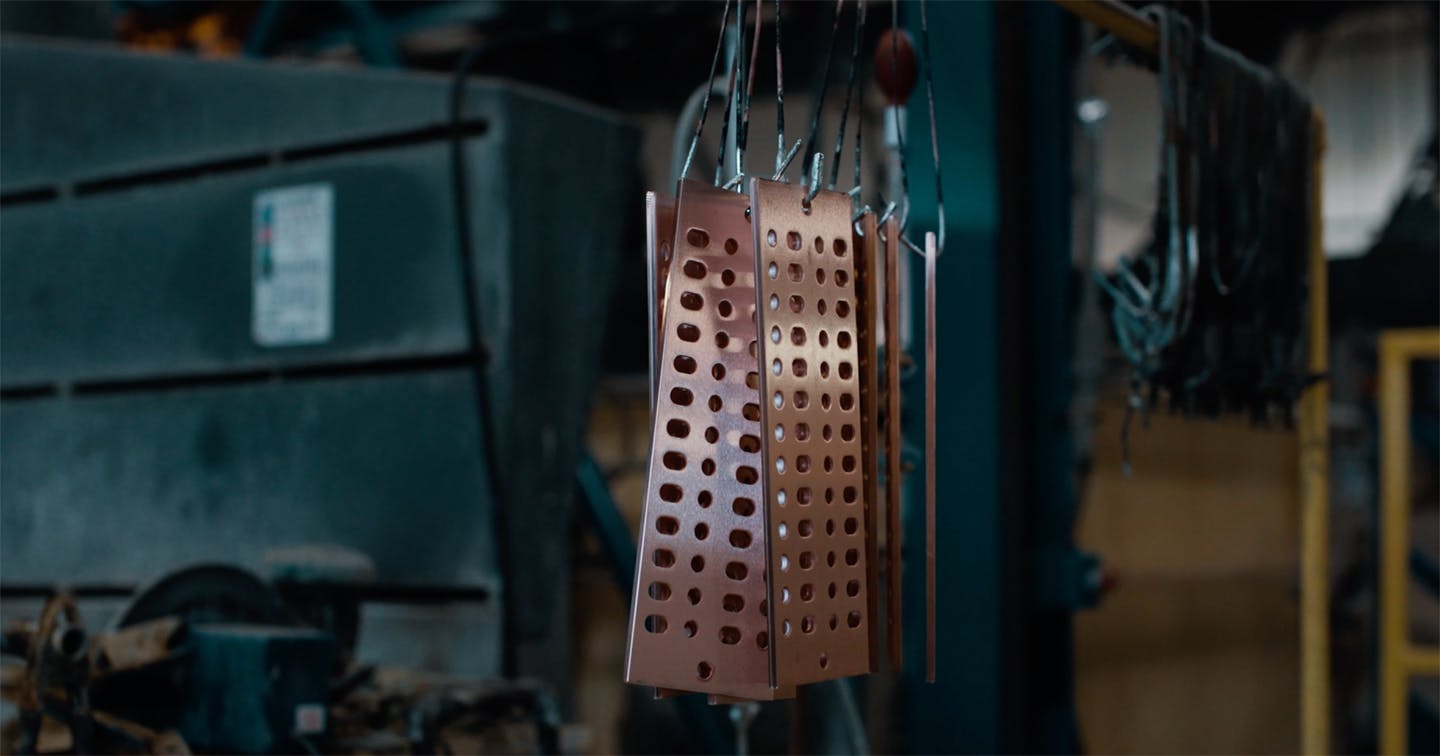

Xometry's DMLS 3D Printing Services

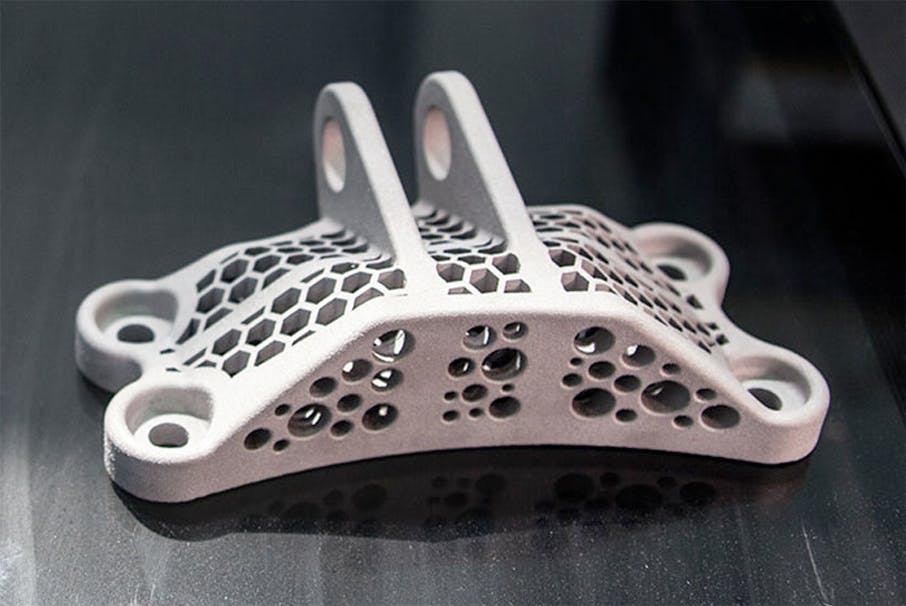

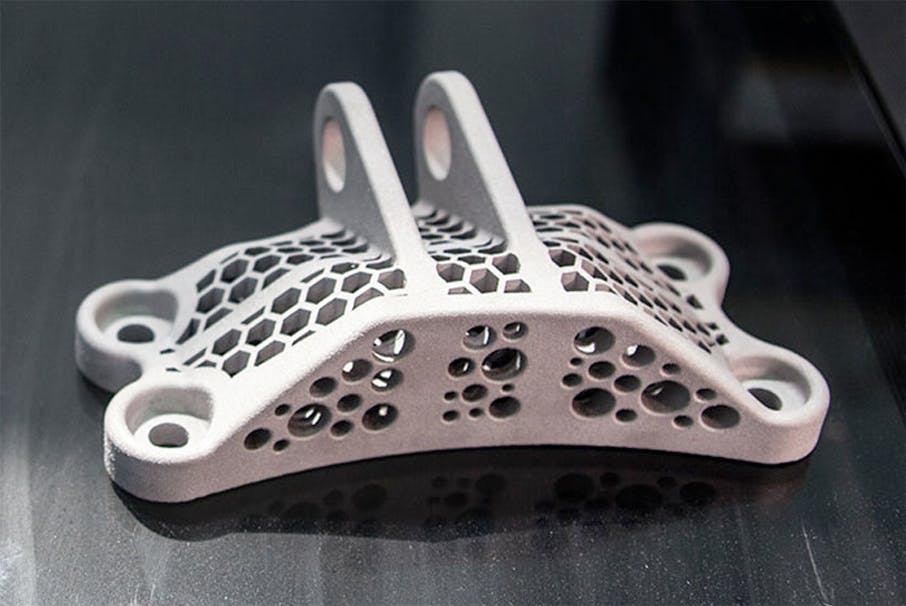

Direct Metal Laser Sintering (DMLS) is a metal 3D printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques. DMLS is often used as a substitution for aluminum or steel metal casting.

Our Direct Metal Laser Sintering metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote (See our Manufacturing Standards for more details). Find out the cost of the parts you need using Direct Metal Laser Sintering or compare the costs of DMLS vs. SLS. Get a free instant quote today.

The Benefits of DMLS 3D Printing

Speed Meets Durability

DMLS is a 3D printing technology that uses metal powder and precision lasers to quickly and accurately create fully-dense parts from a 3D CAD file. DMLS is great for applications that require robust and complex parts in a short lead time. Parts typically ship in 4-8 business days!

High-Performance Materials

Xometry offers DMLS in Aluminum, Stainless Steel (316L and 17-4), Titanium, and Copper.

Production Quality

The durability and strength of DMLS parts up to 980 MPa in stainless steel makes them perfect for end-use applications. These parts are also useful for injection molds, and fully functional late-stage prototypes.

The Trade-Offs With DMLS 3D Printing

DMLS cannot produce the smooth surface finish of a machined part. Pieces can be manually polished, but the process is time-consuming and makes tolerances difficult to maintain. Parts require support structure for overhangs greater than 45 degrees from vertical. Fillets are great to allow surfaces to be self-supporting and grant more freedom of design.

Xometry's HP Multi Jet 3D Printing Services

HP Multi Jet Fusion is a unique 3D printing process that is vastly different from the others on offer. However, it is no less precise, capable of creating high-quality parts up to 10X faster than competing 3D printing processes, allowing you to get to market faster.

Like all powder-based 3D printing processes, HP Multi Jet Fusion builds parts layer by layer, using a fusing agent and heat to set each layer before moving onto the next. In the more traditional 3d printing processes — such as Selective Laser Sintering (SLS), Stereolithography (SLA), or Direct Metal Laser Sintering (DMLS) — each part is imaged, layer by layer, with a single laser beam. HP’s Multi Jet Fusion works a bit more like a traditional ink-jet printer with a printhead that deposits the material, and then a fusing agent, across the entire build plate in one pass, allowing for improved economies of scale when printing in bulk.

HP Multi Jet Fusion is an extremely exciting, robust and flexible addition to Xometry’s manufacturing capabilities. It’s excellent for prototyping, small-batch production runs or as a bridge process to injection molding, allowing you to get a feel for how your parts will perform with minimal upfront costs.

The Benefits of HP Multi Jet

The Power of Nylon

HP MJF prints parts in Nylon, making it a robust and “forgiving” process due to nylon's inherent toughness and flexibility (including a high degree of chemical resistance). Materials can also be sterilized via steam autoclave, Et0, plasma, chemical, and gamma methods. We consider HP Multi Jet Fusion to be one of the best 3D printing processes for both prototyping concept models and for low-volume manufacturing of end-use parts.

Complexity Without Support

Like SLS 3D printing, HP MJF 3D printed parts are built in a self-supporting powder bed which allows fine details, overhangs, and lattice structures to grow easily in all directions. This makes it a great method for complex parts.

Economical and Fast

Because parts are “free-floating” and can be nested together in a bulk build, HP Multi Jet Fusion is a very cost-effective process--even being more economical than Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM) 3D printing in most cases where high quantities are needed.

Rugged Black and Gray Parts

HP Multi Jet Fusion parts have a natural gray surface finish but are solid, jet-black material underneath. The parts can be dyed black and benefit from being able to “scratch black” in applications where they experience high impact, wear, or tear. This makes HP MJF parts ideal for rugged electromechanical enclosures, clips, and prosthetics.

Xometry's Carbon DLS 3D Printing Services

Carbon® uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This technology, along with Carbon’s custom liquid resins, unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory. The Carbon platform enables companies to bring products to market that were never thought possible.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The Benefits of Carbon DLS

End-Use Durability Without Cosmetic Sacrifice

Parts made with Carbon Digital Light Synthesis (Carbon DLS) are great for applications such as automotive, medical, and commercial goods parts due to their ability to be produced quickly and at a low price over volume, while having a smooth surface similar to Stereolithography (SLA) 3D prints. The urethane and epoxy-based materials can withstand high vibration, stress, and are wear-resistant.

Mechanical Property Range

Depending on the material, Carbon DLS parts can be either rigid, flexible, or rubber-like. Material properties compare to urethane cast or injection molded components and some speciality materials offer best-in-class heat resistance.

Economical at Scale

Carbon Digital Light Synthesis can print parts in production at low costs with a shorter lead time compared to traditional tooling methods. Pricing quickly amortizes as the part quantity increases.

The Trade-Offs With Carbon DLS

The platform size is limited, being most suitable for parts under 6” x 4” x 4” and the best economy-of-scale with multiple parts below 3” x 2” x 1”. The support material may leave more pronounced bumps where removed. Single-unit costs are higher than other 3D printing processes.

Xometry's SLS 3D Printing Services

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. SLS is one of the most inexpensive options for industrial 3D printing services because it can build parts in bulk without support structure requirements.

An additive manufacturing layer technology, Selective Laser Sintering involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the selective laser sintering process is repeated until the part is completed.

The Benefits of SLS 3D Printing

The Power of Nylon

SLS prints parts in Nylon 12, making it a robust and “forgiving” process due to nylon's inherent toughness and flexibility (including a high degree of chemical resistance). Nylon can also be sterilized via steam autoclave, Et0, plasma, chemical, and gamma methods. We consider SLS to be one of the best general-use processes for both prototyping concept models and for low-volume manufacturing of end-use parts.

Complexity Without Support

SLS parts are built in a self-supporting powder bed which allows fine details, overhangs, and lattice structures to grow easily in all directions. This makes it a great method for complex parts.

Economical and Fast

Because parts are “free floating” and can be nested together in a build, SLS is a very cost-effective process.

Watertightness and Sealing

Parts that are over 0.040” tend to be water tight and fully dense. Sealing surfaces may require manual smoothing due to the matte finish of sintered plastic.

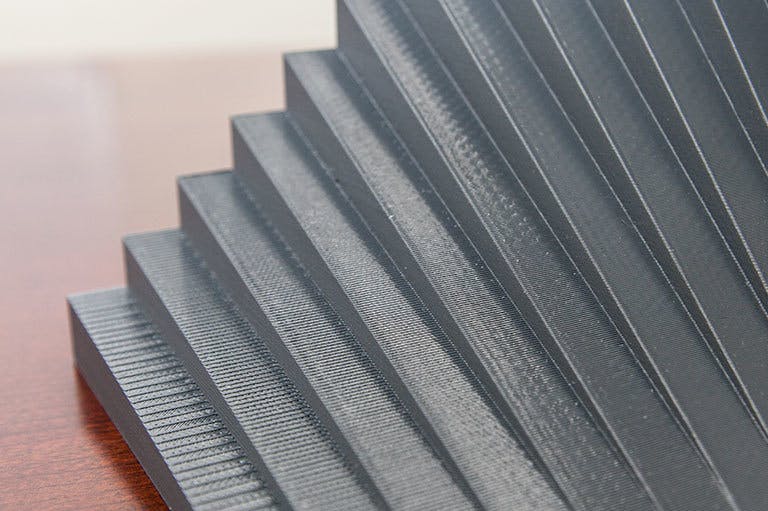

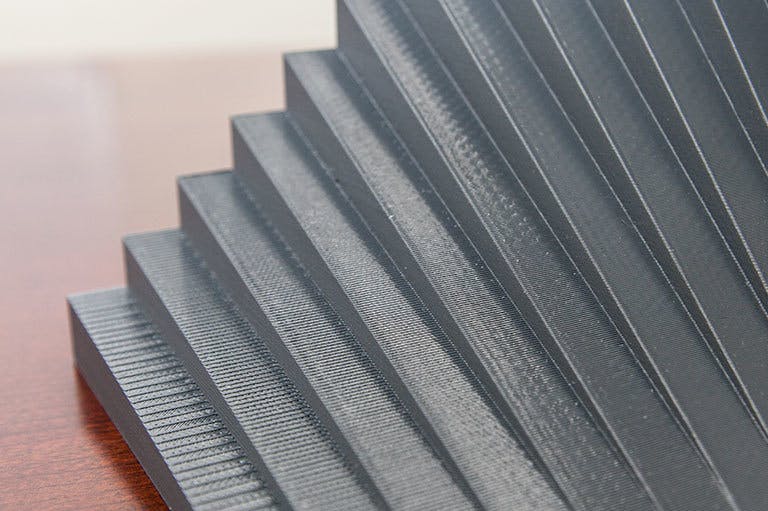

Xometry's FDM 3D Printing Services

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. An FDM machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), and can be lightweighted through multiple infill options.

When ordering through Xometry, you get the benefits of Industrial 3D Printing without the costs associated with buying and maintaining entire machines. Combined with our Instant Quoting Engine, our online 3D Printing service can turn around your FDM parts in as little as 1 day.

Additionally, Xometry's FDM solution offers large build volumes, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem. Our full list of plastic material capabilities is constantly being expanded and updated to fit your unique manufacturing needs.

The Benefits of FDM 3D Printing

All-Around MVP

FDM is widely known for its speed, accuracy, and competitive cost. These factors make it a good choice for concept models, prototypes, and end-use parts.

Trusted Materials with Excellent Mechanical Properties

FDM 3D printing builds parts layer by layer using an extruded thermoplastic filament. Its robust material options make it a great fit for applications that require proven, high-performance plastics such as ABS, Polycarbonate, PPSF, and Ultem.

Color Customization

We offer an enormous amount of customization for FDM parts with 16 colors to choose from, depending on the material.

Xometry's PolyJet 3D Services

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports the ability to print in multiple materials and full color at once and can simulate rubber materials and overmolds.

Xometry’s massive U.S.-based partner network offers a range of higher-end PolyJet machines to support your unique manufacturing requirements, including many multi-material overmold options. Combined with our Instant Quoting Engine, our online 3D Printing service can turn around your Polyjet printing prototypes in as little as 1-2 days, delivering high-quality PolyJet printed parts quickly and at excellent quality.

The Benefits of PolyJet 3D Printing

Incredible Speed and Precision

PolyJet 3D printing builds parts layer by layer using UV light to cure a jetted resin. It offers one of the most advanced industrial 3D Printing solutions available and, due to its simple pre- and post-processing procedures, allows for quick lead times.

Smooth Finish

This process is known for resolving very fine details and producing a smooth surface finish. Polyjet builds parts in fine layers using a UV-cured photopolymer deposited through jetting print heads. It is widely used for models, prototypes, and (low-heat) molds.

A Wide Variety of Properties

Parts in PolyJet can be printed in materials with many different properties from rigid to rubber-like, and even translucent. PolyJet machines can also run multiple materials simultaneously or blend materials together! This drastically increases the variety and characteristics a part can come in.

The Trade-Offs With PolyJet 3D Printing

PolyJet materials tend to be more fragile than FDM or SLS parts. We recommend using it for fit-checks, “feel” checks, trade-show models, and other uses that do not involve harsh environments or impact. Small features on PolyJet parts pose a high risk of breaking off during post-processing. We recommend adding drafts, fillets, and ribs to strengthen the part. Thin and narrow sections of a part are most vulnerable to break. Support material is needed for certain features, which could reduce the freedom of design because removal of support may risk breaking fragile features.

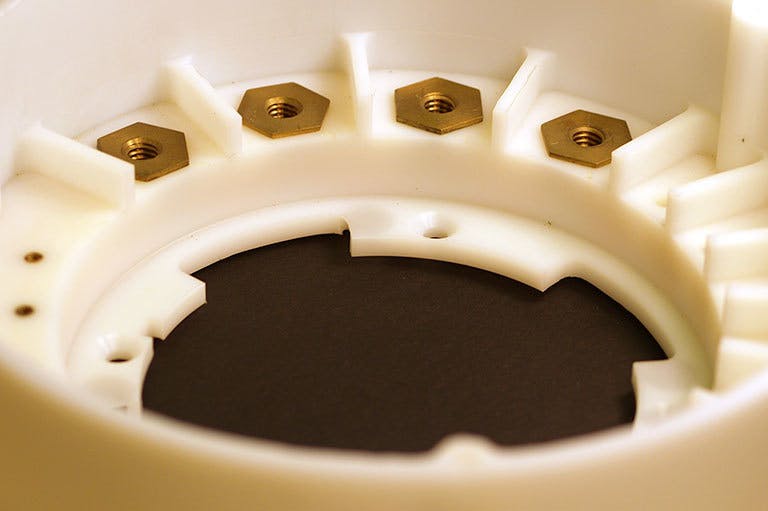

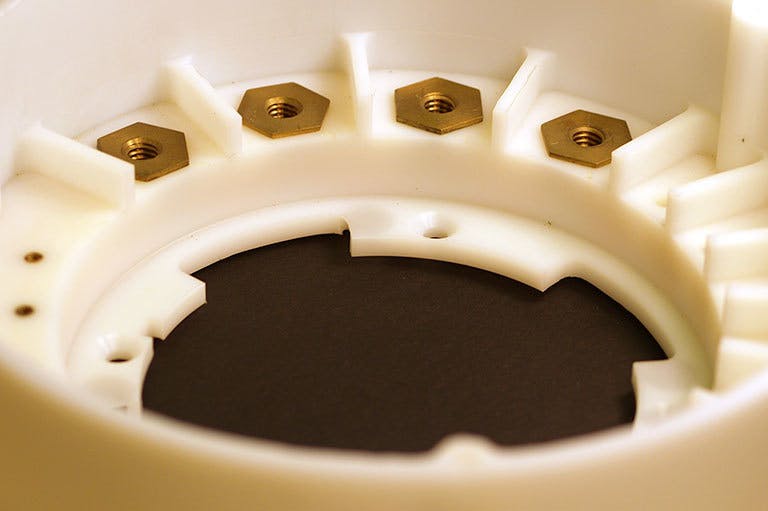

Xometry's Injection Molding Services

Xometry delivers high-quality, on-demand injection molded parts. Injection molding is the cheapest process to make a plastic part at scale by offering consistent quality for mid-to-high volume manufacturing. Molding also has the highest variety of materials, colors, and configurations compared to CNC machining or even 3D printing. Beyond materials, injection molded parts can have custom cosmetics, polishes, or surface textures.

Xometry takes a “have it your way” approach to molding. We specialize in complex projects, typically requiring side action or hand loaded inserts. Our goal is to provide a long term solution, moving beyond rapid prototyping, with dedicated project managers and engineering experts to communicate through all project stages from design to production.

The Benefits of Injection Molding

Variety of Material Properties

The Injection Molding process offers a vast array of plastic resins to work with. These materials have been developed to meet specific requirements for strength, high temperature and chemical resistance, abrasion resistance, and low friction.

Thin Walls? No Problem

Unlike many other manufacturing methods, thin walls actually benefit Injection Molded parts by reducing cycle time and, by extension, part cost.

Precise Surface Finish

Molded parts will carry the exact surface finish of their molds, allowing for greater control over the finished product.

Economy of Scale

Since large numbers of uniform parts can be produced from a single mold, Injection Molding is an excellent choice for production runs—the more you buy, the less you spend per unit.

The Trade-Offs With Injection Molding

Shrinkage varies based on material and must be compensated for in the mold. Cost-prohibitive in small quantities, Injection Molding is best for low-volume production runs. The molded part will pick up even the smallest imperfection in the mold surfaces, so additional finishing of the mold may be required.

Xometry's Urethane Casting Services

Urethane casting provides end-use, rigid or flexible plastic parts with production-level quality. Built without expensive and time-consuming hard tooling, our urethane casting process uses a 3D printed master pattern and silicone molds to deliver high-quality, short-run parts up to 30” long. The finished dimensions of urethane cast parts depend on the accuracy of the master model, part geometry and casting material. In general, a shrinkage rate of + 0.15% is expected.

Xometry supports any urethane casting process, material or finish you could need. Our extensive network of SLA and Polyjet 3D printing partners means we can handle everything from the master pattern and mold-making, to the production casting of parts and custom finishes. With more than 4,000 vetted manufacturing partner facilities across the U.S., Xometry is able to pair your part order with the machine shop best suited to handle the quality, surface finishes, performance, and color requirements you need — resulting in competitive prices and ideal lead times for your projects.

The Benefits of Urethane Casting

End-Use Durability

Parts made with urethane casting are great for applications such as automotive and aircraft parts due to their ability to be produced quickly and at a low price, while being durable enough for end-use.

Mechanical Property Range

Depending on the mixture, urethane casted parts can be either rigid, flexible, or rubber-like and are even sufficient for end-use applications due to this method’s high impact strength, abrasion resistance, and resistance to heat.

Faster Than Injection Molding

Urethane casted parts are known for “bridge tooling” or “soft tooling” when compared to Injection Molded parts because of the faster rate of production and lower fixed cost.

The Benefits of Xometry's Finishing Services

Competitive Pricing

Access a deep network of world-class finishers, helping you find the suppliers you need at competitive prices.

Save Time

Free up your team to focus on high-value projects and let our tech handle the time-consuming RFQ process.

One-Stop Shop

Xometry's new lightning-fast finishing services offers two-hour quoting on most orders, competitive pricing, and two-day delivery on standard finishing services without expediting fees.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.