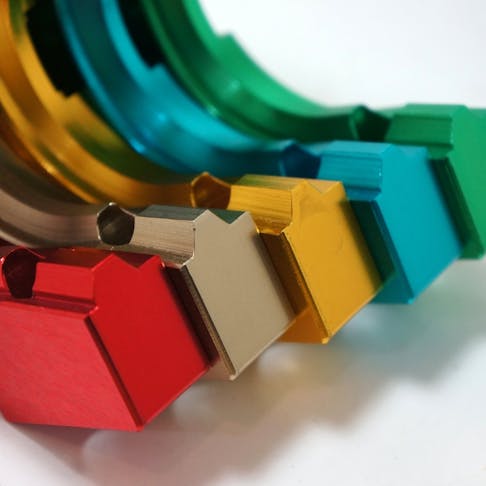

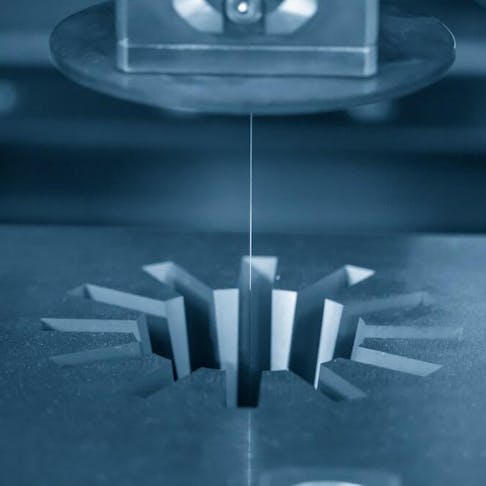

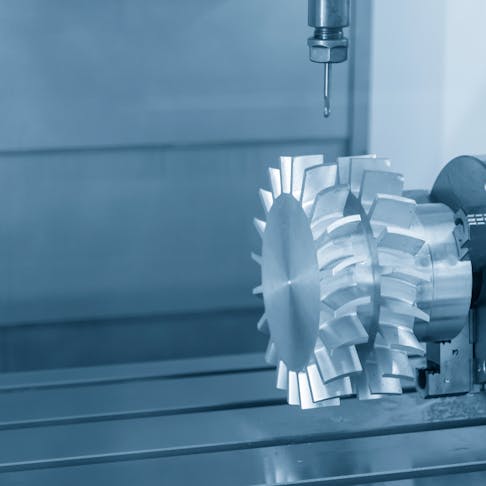

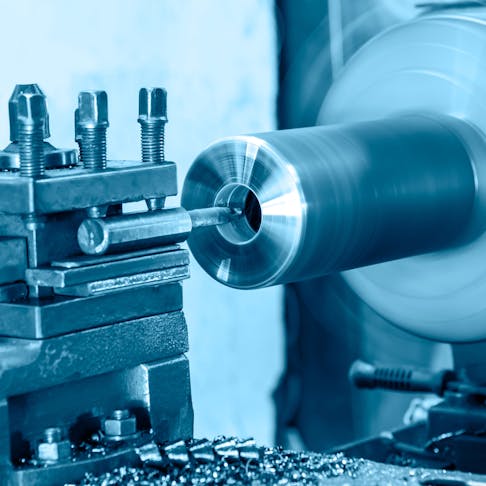

Machining Design

The latest news, trends, and manufacturing design tips for custom machined and fabricated parts.

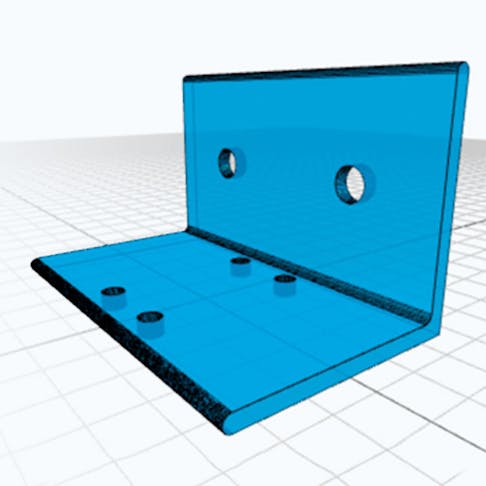

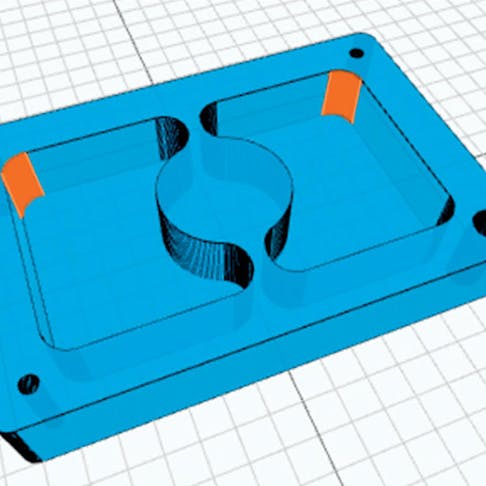

How to Start Designing with Common Sheet Metal Features in Autodesk Inventor

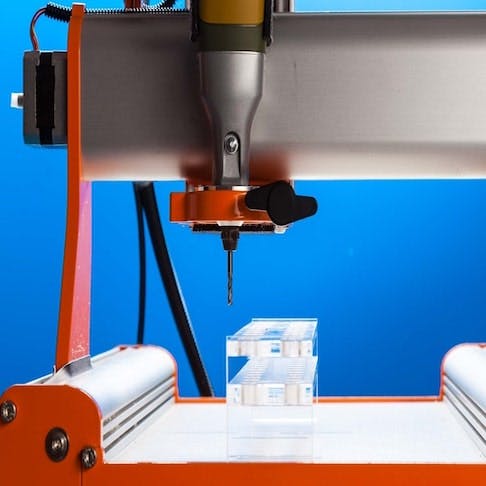

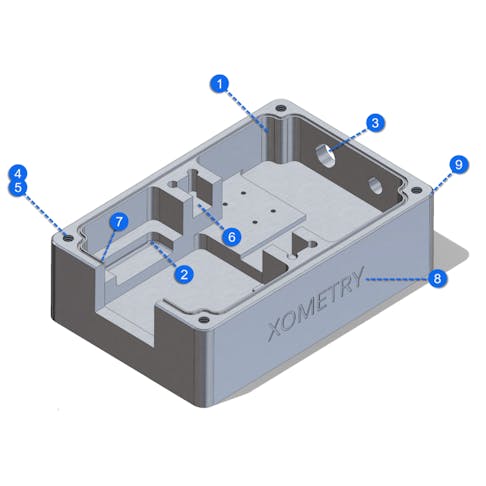

Design Reference Poster: 9 Cost-Saving CNC Design Tips

Call: +1-800-983-1959

Email: support@xometry.com

The latest news, trends, and manufacturing design tips for custom machined and fabricated parts.

How to Start Designing with Common Sheet Metal Features in Autodesk Inventor

Design Reference Poster: 9 Cost-Saving CNC Design Tips