Copper 3D Printing Service on Xometry

Get instant online quotes on custom copper 3D printed parts. Free shipping on all US orders. ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified. Subject to availability. Xometry doesn't guarantee that we can provide this service at any given time.

Xometry offers high quality copper 3D printing services on a variety of platforms and for a wide range of industries. Additive manufacturing with metal powder allows for the creation of pure copper or copper alloy parts with high thermal and electrical conductivity, antimicrobial, and aesthetic qualities. In copper 3D printing, copper powder is fused together either with heat, plastic binder, or other material to produce complex copper parts without the need for brazed or welded assemblies. 3D printed copper parts are used in applications where high electrical conductivity or thermal conductivity are needed such as induction coils, heat sinks, or in applications where designers must eliminate brazed or welded assemblies.

Copper 3D Printing Processes

Copper 3D printing can be achieved using a number of methods. Note that certain systems can produce pure copper parts while others are restricted to copper-impregnated materials, however many of the same material properties are shared between prints despite their differing compositions of copper.

- Fused Deposition Modeling (FDM)

- Direct Metal Laser Sintering (DMLS)

Fused Deposition Modeling (FDM)

Also known sometimes as fused filament fabrication (FFF), fused deposition modeling is a process In which filament is fed into a heated extruder head that is controlled by a computer-guided XYZ gantry to print 3D parts in a layer-by-layer process. It is the most common 3D printing technology for both hobby and professional users. Though not typically used in printing metal parts, copper-impregnated filaments are available that allow these prints to possess some of the beneficial properties of the metal. If final fully metal prints are desired, some copper FDM filaments can be baked in an oven to eliminate the plastic binder material, leaving behind a copper part (note that this may require a proprietary FDM printer that can handle this type of filament). To learn more, visit our guide on FDM 3D Printing.

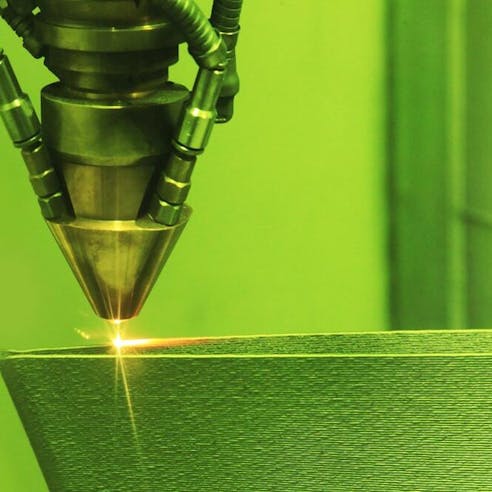

Direct Metal Laser Sintering (DMLS)

DMLS printers work by selectively melting a metal powder with a high-powered laser beam in a contained inert atmosphere (typically nitrogen or argon gas). The bed of powder metal is kept unoxidized thanks to the inert atmosphere, while a laser beam scans the cross-section of a part layer on this powder and melts the metal particles together. Some machines have up to four independent lasers that can all operate on the same layer simultaneously, effectively quadrupling the print speed. Once a layer has been melted together, the print bed moves down and another layer of metal powder is rolled onto the print bed until the full part is complete. Once the part is printed, any support material must be removed and the part is removed from the powder bed and brought to successive post-processing steps such as additional sintering, heat treatment, and surface finishing. To learn more, visit our guide on Direct Metal Laser Sintering 3D Printing.

Copper 3D Printing Properties

Copper 3D prints have unique advantages over other kinds of metal 3D printed parts. Below are some of these benefits:

- Thermal and Electrical Conductivity

- Aesthetics

- Antimicrobial

- Low Cost

- Workability

Thermal and Electrical Conductivity

Copper has one of the lowest resistivity measures across all metals, second only to silver– this means that it is also one of the best conductors of electricity and heat thanks to the lack of resistance in its structure. Copper 3D prints retain this property and are ideal for electrical or heat applications where this energy is directed through the part, such as in bus bars or heat exchangers.

Aesthetics

Copper is an incredibly attractive metal, both with a polish and a patina – this makes it an ideal metal for applications where aesthetics are important. Decorative copper parts can enhance the appearance of a project with its turquoise-like oxidation or polished mirror shine, as well as several anodized coating options.

Antimicrobial

Due to its chemical interactions with cell membranes and virus coats, copper is the best surface to prevent the spread of pathogens. Copper parts are naturally antimicrobial and can be especially useful for medical or public applications where pathogen counts must be minimized.

Low Cost

Copper (both as pure copper and copper minerals) occurs naturally in a variety of forms across environments and in the Earth’s crust, making it highly available for extraction and refinement. Its abundance paired with its other properties makes it an ideal engineering material for wiring, electrical components, and other high-volume applications.

Workability

Copper has high ductility, making it a highly malleable and workable metal. Despite its work hardening as it experiences mechanical stressors, copper can be annealed to soften the grains structure back to its malleable state, also making it a forgiving material.

Ready to 3D Print Copper Parts?

Copper 3D Printing Applications

Designers can apply copper 3D printing to numerous applications. Below are some of the most common uses of 3D printed copper in industry.

- Low-volume Production Parts

- Tooling

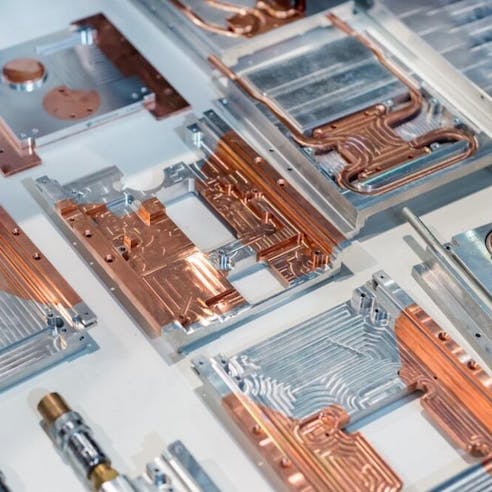

- Heat Exchangers

- Functional Prototypes

Low-volume Production Parts

If an application calls for a one-off part or does not need to scale to commercial volumes, then copper 3D printing is much more economical when compared to other subtractive manufacturing processes. Low-volume production parts benefit from the set-it-and-forget-it nature of additive manufacturing technology and from its enhanced capabilities to create highly complex parts.

Tooling

Tooling that requires high thermal or electrical conductivity can easily be printed with copper 3D printing. Spot welding arms, conductive nodes, battery connections, or any other tooling part is easy to produce and replace using additive manufacturing technology.

Heat Exchangers

Copper is highly sought after for its heat-conducting properties when implemented in heat exchangers, but they can be difficult to produce using traditional techniques due to their complexity. Not only can copper 3D printing easily produce heat exchanger parts, but the technology can be leveraged so that designs can now perform conformal cooling, where complex internal cooling channels can be designed within the part so that coolant can better reach the hottest areas of a part.

Functional Prototypes

3D printing has always been an amazing prototyping tool thanks to its speed and accuracy, but with the addition of copper as a material choice, it allows designers even more versatility in presenting their designs. Printing copper prototypes can help visualize the weight, functionality, or aesthetic characteristics of a project with little to no added fabrication complexity.

Why Choose Xometry for Copper 3D Printing?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.