Laser Engraving Services by Xometry

High-quality Laser Engraved Parts in Days Not Weeks | Free Standard Shipping on All US Orders

Xometry is an excellent laser engraving service provider dedicated to providing products of the highest caliber. Laser engraving is a precise and adaptable technique for etching designs or markings onto a variety of materials. To meet the needs of a wide range of clients, Xometry provides a variety of laser engraving services, including deep engraving, surface engraving, and rotary engraving.

Modern laser technologies are used by Xometry to guarantee astounding accuracy and fine detailing. Permanent marking, high precision, and the ability to engrave complex designs or text are just a few benefits of laser engraving. The top three applications of laser engraving services are: personalization and customization of items such as gifts, promotional products, and awards; industrial applications for part identification and branding; and artistic creations on materials like wood, acrylic, or glass. Xometry's laser engraving services offer top-notch quality and a variety of techniques to meet unique needs.

What Is Laser Engraving?

Laser engraving involves marking a surface with a laser beam to produce text and graphics. By focusing the laser beam on the material's surface, it heats and vaporizes the material in a controlled manner to produce exact and long-lasting markings.

Types of Laser Engraving Processes for Different Materials

Laser engraving can be performed on a range of materials, including metal, leather, glass, and wood, as described in the sections below:

- Metal Laser Engraving

- Leather Laser Engraving

- Wood Laser Engraving

Metal Laser Engraving

Using a laser, metal surfaces can be etched or marked with designs using a tightly focused beam of light. Metal laser engraving involves the removal of material by vaporizing or melting it, leaving behind engravings that are both durable and in high contrast. This method is often used in the jewelry and manufacturing industries and in the private or commercial production of customized gifts.

Leather Laser Engraving

Leather laser engraving is the process of using a laser beam to create patterns or designs on leather surfaces, which results in a debossed, sunken, or depressed appearance. The top layer of the leather is burned or vaporized by the laser, leaving behind fine, detailed engravings. The fashion industry uses leather laser engraving extensively to personalize leather products like wallets, belts, and bags, as well as to add decorative accents to footwear and upholstery.

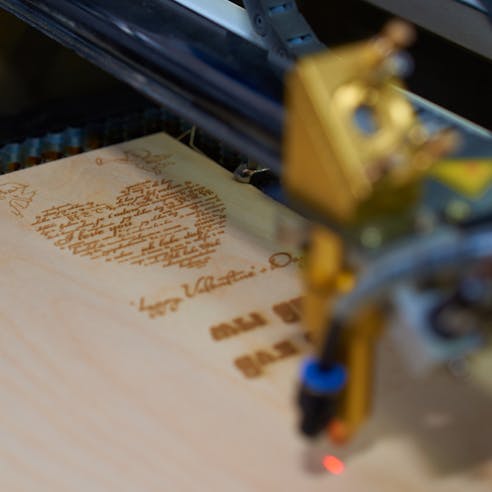

Wood Laser Engraving

Wood laser engraving involves using a laser beam to etch or cut designs onto wooden surfaces, creating permanent marks. The laser vaporizes or burns the wood, creating detailed and precise engravings. This technique is popular in various industries, including woodworking, crafts, signage, and home decor. Wood laser engraving is utilized to produce intricate designs, texts, and even three-dimensional relief carvings on wooden objects like furniture, plaques, ornaments, and wooden panels.

Laser Engraving Technologies

A variety of laser machine types are employed for laser engraving services. These are the three primary categories:

- LED Laser

- CO2 Laser

- Fiber Laser

LED Laser

LED (Light-emitting diode) lasers, also referred to as diode lasers, permit the passage of light and energy in a focused beam by limiting their flow to one direction. These lasers can engrave on a variety of materials, including leather, wood, and acrylic, and are portable and reasonably priced. For smaller-scale engraving jobs and hobbyist applications, LED lasers are commonly used.

CO2 Laser

CO2 lasers utilize a gas mixture, primarily carbon dioxide and other gasses such as helium (He) and nitrogen (N2), as the active medium. These lasers produce a high-intensity infrared beam that can be focused to create precise and detailed engravings on a wide range of materials, including wood, glass, acrylic, leather, and plastics. CO2 lasers are versatile and are frequently used in industrial and commercial settings for both engraving and cutting applications.

Fiber Laser

Fiber lasers use optical fibers doped with rare-earth elements, such as erbium or ytterbium, as the gain medium. They generate a laser beam that is highly suited for engraving on metal surfaces, including stainless steel, aluminum, brass, and more. Fiber lasers offer excellent engraving precision and high speed and are often used in industries such as jewelry-making, vehicle manufacture, and the fabrication of electronics.

Laser Engraving Advantages

Laser engraving is a popular option in many industries because it has several benefits over conventional engraving techniques. Here are some of the main benefits of laser engraving, as well as instances where these benefits are especially helpful:

- Accuracy

- Fast Fulfillment

- Flexibility

- Tactile Markings

- Wear and Tear Resistant

Accuracy

Intricate designs and minute details are possible thanks to the exceptional precision and accuracy of laser engraving. Laser engraving enables much smaller detail sizes when compared to traditional engraving techniques. It can create clear scripts that may need a magnifying glass to read, as well as tiny letters and intricate patterns that are discernible to the unaided eye. Without magnification, the GIA mark on a diamond cannot be seen. A loupe or magnifier strength of 20x is typically advised to read the laser-inscribed GIA serial number. This level of accuracy is especially useful in fields like jewelry production, where fine engravings on tiny surfaces are required to improve the aesthetic appeal of goods.

Fast Fulfillment

Laser engraving is a quick process that can be completed efficiently, enabling fast turnaround times. This advantage is valuable in industries that require rapid production and delivery, such as the personalized gift industry. For instance, a company specializing in customized trophies can use laser engraving to quickly engrave names and messages on awards, ensuring timely delivery.

Flexibility

Laser engraving is suitable for a variety of applications because of its flexibility. It is possible to perform laser engraving on a variety of materials, including metals, plastics, glass, wood, and more. To serve a diverse customer base, a manufacturer of promotional products might use laser engraving to customize a range of products, such as keychains, pens, and phone cases, made from various materials.

Tactile Markings

Laser engraving can produce tactile markings by modifying the depth and texture of the engraved surface. This is advantageous for industries like the medical device industry that demand enhanced grip or tactile identification. The blind community may benefit from using tactile markings created using laser engraving. On a variety of materials, laser engraving can produce raised patterns or braille characters by altering the depth and texture of the engraved surface. By enabling the blind to interact with and perceive visual content through touch, these tactile markings have the potential to provide information, improve accessibility, and broaden the horizons of the blind.

Wear and Tear Resistant

Laser-engraved markings are highly durable and resistant to wear and tear. This benefit is especially useful for applications like industrial labels and serial numbers on machinery where durability and permanence are essential. Equipment identification tags that have been laser engraved can withstand harsh conditions, including chemical exposure, without fading or degrading.

In need of custom laser engraving services?

Laser Engraving Disadvantages

Despite being a well-liked and effective technique for leaving precise and long-lasting markings, laser engraving has limitations. Here are two significant drawbacks of laser engraving:

- Uses More Energy

- Less Versatile

Uses More Energy

Typically, laser engraving calls for powerful lasers that use a lot of energy. Higher operational costs and a greater negative impact on the environment may result from this compared to alternative engraving methods or smaller-scale engraving. Laser engraving can result in higher electricity costs and a larger carbon footprint, especially when large-scale engraving is performed regularly. In comparison to other engraving methods, such as mechanical engraving or chemical etching, laser engraving tends to have higher energy requirements. This drawback is more pronounced in circumstances where energy efficiency is a top priority, such as in environmentally friendly manufacturing processes or locations with scarce energy resources.

Less Versatile

Laser engraving is highly effective at engraving and etching on certain materials, such as wood, metal, glass, and acrylic. When it comes to engraving or marking on other materials, it might not be the best process choice. For example, the production of hazardous gasses or dust during laser processes may make materials like PVC (polyvinyl chloride), carbon-based materials, and PVB (polyvinyl butyral) less than ideal choices. Alternative techniques like screen printing, direct printing, or heat transfer may be more appropriate in such circumstances. Working with unusual materials or when a broad range of material customization options is required can be challenging due to the limited versatility of laser engraving.

Laser Engraving Applications

Despite its limitations in terms of versatility, laser engraving remains a highly adaptable technology with extensive applications. Here are a few typical applications for laser engraving, along with some examples of industries that profit from them:

- Awards and Trophies

- Barcode Creation

- Decorative or Commemorative Annotations

- Medical and Electronic Components

- Signage

Awards and Trophies

Many people use laser engraving to customize trophies and awards. Laser engraving supports intricate and exact designs for text, logos, and graphics. For their recognition programs, businesses in sectors like sports, entertainment, corporate, and academic institutions frequently use laser engraving.

Barcode Creation

Barcodes can be engraved with laser technology onto a variety of materials, including metal and plastic, to produce long-lasting, high-quality codes. Laser engraving is useful in sectors like manufacturing, logistics, retail, and healthcare where precise and scannable barcodes are required for product tracking and inventory management.

Decorative or Commemorative Annotations

Laser engraving can be used to add decorative or commemorative annotations on a variety of items. It can be used to engrave intricate patterns, images, names, dates, or messages on materials like wood, metal, glass, leather, and acrylic. Industries such as giftware, jewelry, personalization services, and memorabilia benefit from this application.

Medical and Electronic Components

Laser engraving is crucial in the medical and electronics industries for marking and branding various components and devices. It allows for permanent, noncontact marking on materials like metals, plastics, and ceramics, ensuring traceability, identification, and compliance with industry regulations.

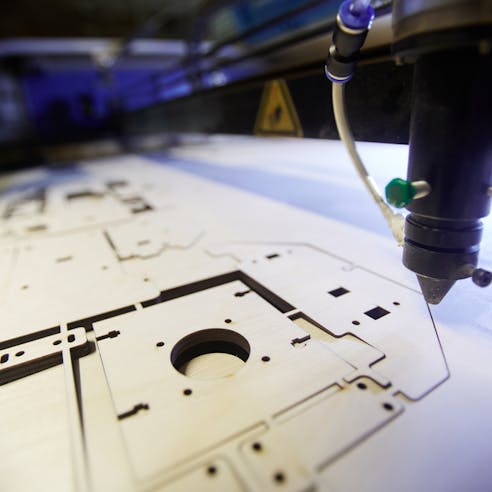

Signage

Laser engraving is a common technique for producing enduring and high-quality signage. It makes it possible to precisely cut and engrave materials like foam, metal, acrylic, and wood, producing finely detailed artwork and clear text. Laser-engraved signage is essential for branding, wayfinding, and advertising in sectors like advertising, retail, hospitality, and interior design.

Alternatives to Laser Engraving Service

Some alternative Xometry capabilities that can be used instead of laser engraving service include:

- CNC Machining

- 3D Printing

- Waterjet Cutting

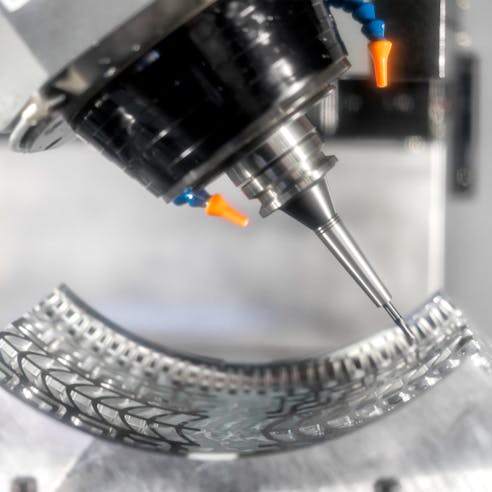

- CNC Machining: CNC machining is a subtractive manufacturing process that uses high-speed cutting tools to create a part or a design. Xometry provides precision machining services to produce intricate designs on a variety of materials.

- 3D Printing: 3D printing is an additive manufacturing process that creates a part layer by layer using various 3D printing technology such as SLA, SLS, and FDM. Xometry provides 3D printing services that can be used to add customized designs or textures to objects.

- Waterjet Cutting: Waterjet cutting is a manufacturing process that uses a high-velocity stream of water to remove material. Xometry offers waterjet cutting services to etch patterns or designs onto a variety of materials.

Why Choose Xometry for Laser Engraving Services?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.