3D Printing History – When Was 3D Printing Invented?

The invention of 3D printing involved a combination of scientific research, technological innovation, patents, and commercialization efforts, leading to the widespread adoption of additive manufacturing across industries. While the end goal of low-cost parts of high precision, strength, and production speed is common to all of the technologies, the diversity of methods and materials is continuing to expand at an increasing pace.

This article will discuss what 3D printing is and how the solutions are becoming more diverse and complex as the pace of innovation increases.

What Is the Historical Origin of 3D Printing?

The historical origin of 3D printing lies in R&D performed in the 1980s when the co-founder of 3D Systems, Chuck Hull, invented stereolithography (SLA) in 1983. SLA was one of the earliest forms of 3D printing technology, utilizing ultraviolet (UV) light to selectively cure layers of liquid photopolymer resin, creating solid objects layer by layer.

This breakthrough paved the way for subsequent advancements in additive manufacturing, including other techniques like selective laser sintering (SLS) and fused deposition modeling (FDM®), leading to the widespread adoption of 3D printing across various industries.

When Did 3D Printing Started?

Chuck Hull created the first SLA machine, called the “STL-1” or “SLA-1,” in the early 1980s. This machine used a process called photopolymerization, in which ultraviolet (UV) light was used to selectively cure layers of liquid photopolymer resin, solidifying them into desired shapes.

Hull patented this breakthrough in 1986, which led to the commercialization of SLA systems by his company, 3D Systems. The invention of SLA marked the beginning of the additive-manufacturing revolution and laid the foundation for subsequent advancements in 3D printing technology.

How Did 3D Printing Start?

The first commercially produced SLA machine was launched by 3D Systems in 1988, and its impact on the prototyping sector was profound, bringing previously impossible solutions into the hands of designers and engineers.

This was rapidly followed by the development and commercialization of FDM® by Stratasys, offering lower-resolution models, using a lower-cost approach, and built from materials that more closely resembled “real” production.

Early agencies and in-house services quickly revolutionized the product development process and began the process of shortening design cycles and accelerating the design-sign-off process by improving design validation at the earliest stages.

When Was the First 3D Printer Introduced?

The adoption of 3D printing was an organic process that initially occurred over several years, as conservative thinking gave way to a more rapidly testable process that facilitated exploration. Combined with the coincident advent of 3D CAD-CAM systems, product design became a more flexible and less-black-art field.

The first SLA machines in 1989 heralded a revolution, but that change was slow moving and it is still in motion.

Who Invented the First 3D Printer?

The two technologies that broke the first ground in additive manufacturing were: SLA, developed by Chuck Hull and commercialized by 3D Systems from 1988/89, and FDM®, developed by Scott Crump at around the same time and commercialized soon after SLA by Stratasys.

What Are the Significant Events That Happened During the 1980s to 3D Printing History?

During the 1980s, the following seminal events shaped the origin and early history of 3D printing:

- In 1983, Chuck Hull first developed the concept that became SLA, the earliest 3D printing technology, commercialized by 3D Systems in 1988.

- Carl Deckard and Joseph Beaman developed selective laser sintering (SLS) at the University of Texas in 1986, bringing another of the foundational technologies in additive manufacturing to early-stage development.

- Scott Crump patented fused deposition modeling (FDM®) in 1989, laying the groundwork for the commercialization of FDM®-based 3D printers by Stratasys.

These milestones mark the birth of 3D printing and set the stage for its ongoing and rapid evolution in subsequent decades.

What Are the Significant Events That Happened During the 1990s to 3D Printing History?

During the 1990s, the following pivotal events contributed to the accelerating evolution of 3D printing:

- Commercialization of SLA and SLS technologies by companies like 3D Systems and DTM Corporation led to increased adoption across many higher-value and higher-tooling-cost design sectors.

- The introduction of desktop 3D printers, beginning with the FDM® technology by Stratasys, began making 3D printing more accessible to businesses and eventually hobby/enthusiast users.

- Expansion of applications into all industries, driven by advancements in materials, printing techniques, increased agency competition, falling costs to users, and improved post-processing methods.

- Development of rapid prototyping and rapid tooling applications, streamlining product-development cycles and manufacturing processes.

These milestones cemented 3D printing as the transformative technology it was rapidly becoming, with widespread and near-universal sector application.

What Are the Significant Events That Happened During the 2000s to 3D Printing History?

During the 2000s, the following significant developments and technological events propelled the advancement of 3D printing:

- Development of new 3D printing technologies, including direct metal laser sintering (DMLS) and electron beam melting (EBM), enabling the production of full-density, finished-size metal parts with complex geometries.

- Introduction of low-cost desktop 3D printers by companies like MakerBot, Ultimaker, and Prusa Research, disseminated access to 3D printing technology down to the comfortable reach of individuals and small businesses.

- Expansion of applications into healthcare, with the use of 3D printing for medical implants, prostheses, early bioprinting, and patient-specific surgical guides.

- Continued refinement and expansion of materials and increased diversification of printing processes and software all served to enhance the capabilities and precision of 3D printing technology.

The largest effect of the developments of this period was the demystification of additive manufacturing and the increasing acceptance of at least the idea of higher-level processes as having potential for finished product manufacture on small to medium scale.

What Are the Significant Events That Happened During the 2010s to 3D Printing History?

During the 2010s, the pace of development increased yet further, shaping a variety of trajectories in the increasingly diverse capabilities that together represent 3D printing. Some of these are:

- Advances in bioprinting technology enabled the printing of collagen frameworks to be growth-populated by living tissues during this period. Increased experimentation with live-cell printing for medical research and potential transplantation began at this time, as techniques developed.

- Growth of 3D printing in aerospace and automotive industries for manufacturing end-use parts, such as: aircraft/rocket combustion chamber parts and automotive prototypes, restoration parts, and even exploration towards “mass” production.

- Penetration of 3D printing into construction, with the development of large-scale additive manufacturing techniques for building structures by liquid extrusion of cement-type pastes.

- Introduction of metal 3D printing systems capable of producing high-resolution, full-density metal parts for aerospace, automotive, and medical applications. Two basic approaches were developed — polymer-bonded parts that are post-printing sintered AND directly applied local melting for final off-machine finished components.

- Adoption of 3D printing in education, maker spaces, and DIY communities, fostering innovation and creativity.

What Are the Significant Events That Happened During the 2020s to 3D Printing History?

Significant events in 3D printing during the 2020s include:

- 3D printing played a well-publicized role in producing personal protective equipment (PPE), ventilator experiments, and nasopharyngeal swabs. Much of this was publicity-driven and not suitable for real use, but the profile effects on the sector were profound.

- Increasing focus on eco-friendly materials and processes, as well as recycling and circular economy initiatives. This includes increasing the use of recycled and bio-sourced filaments for FFF/FDM®, increased use of water-soluble and biologically inert support materials, and efforts to reduce waste and toxicity in many processes.

- NASA, the US military, and private companies began to utilize additive manufacturing for prototyping and manufacturing components for spacecraft and habitats.

- Progress in printing complex tissues and organs for medical applications and regenerative medicine continued, though this remains generally experimental.

- Moves towards atomic-scale additive manufacturing process research that is very early stage, small scale, but rapidly developing.

- Increasing use of 3D printing for mass customization, spare-parts production, and tooling across various industries.

The pace of release of new commercial executions of existing technologies, entirely new processes, and diversification of materials towards “real” rather than prototype properties and end-use part characteristics is still accelerating.

When Did 3D Printing in the Food Industry Start?

3D printing in the food industry started gaining momentum in experimentation in the early 2010s. While the concept of 3D printing food has been explored for several years, notable developments began around 2011–2012 when researchers and chefs started experimenting with 3D printers modified to extrude food materials. The basic concept differs only in automation from the complex, 3D hand-decorating of cakes and confectionery which already has a long history.

One of the early pioneers in the additive manufacture of food was Barcelona-based Natural Machines, which introduced the Foodini 3D food printer in 2014. Subsequently, various companies, research institutions, and culinary professionals have been exploring the potential of 3D printing technology to create customized, visually appealing food items, ranging from confectionery and chocolate to pasta, meat substitutes, and even entire meals.

To learn more, see our full guide on 3D Printing in Food.

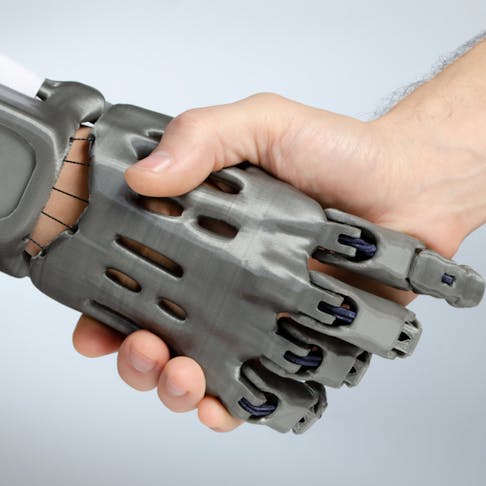

When Did 3D Printing in Prosthetics Start?

3D printing in prosthetics began to gain traction beyond the conceptual/visualization level in the early to mid-2010s. The concept had been explored in research settings before that, with few long-term functioning outcomes.

One of the significant early developments occurred in 2011 when a South African carpenter named Richard Van As collaborated with an American prop maker, Ivan Owen, to create a 3D-printed prosthetic hand for a young boy named Liam. Their design, known as the "Robohand," was open-source and widely shared online, sparking interest in using 3D printing technology to create affordable and customizable prosthetic devices. Since then, 3D printing has been increasingly utilized in the prosthetics field for its ability to produce personalized, lightweight, and cost-effective prosthetic limbs and components. Improving materials, wider dispersal of capabilities, and a deepening understanding of the implications of the approach are driving constant innovation in the space.

To learn more, see our full guide on 3D Printing in Prosthetics.

When Did 3D Bioprinting Start?

3D bioprinting, the process of creating three-dimensional biological structures using living cells, began to emerge as a research field in the early 2000s. One of the earliest demonstrations of 3D bioprinting occurred in 2003 when Thomas Boland, a researcher at Clemson University, developed a technique to print living cells onto biocompatible scaffolds using an inkjet-based bioprinter. This marked a significant milestone in the development of 3D bioprinting technology. Subsequent advancements in materials science, bioengineering, and additive manufacturing techniques have led to the development of more sophisticated 3D bioprinting systems capable of printing complex tissues and organ-like structures. Today, 3D bioprinting holds immense promise for: tissue engineering, regenerative medicine, drug discovery, and personalized medicine applications.

What Is the Current Status of 3D Printing?

3D printing has evolved into a mature and diverse range of technologies, with methodologies and applications ranging from the microscopic to built environments; from biology to high technology; and from polymers and composites to metals, food, and biological materials. The huge range of applications runs across all industries, markets, and geographies.

3D printing’s status reflects a thriving group of rapidly diverging industries whose common ground in additive manufacturing is becoming mundane, even as the applications become embedded in and central to the industries/sectors they supply. Ongoing continuous innovation is resulting in expanding capabilities and a growing diversity of applications across all sectors.

As the core technologies continue to advance and evolve in complexity and capability, 3D printing is poised to increase the criticality of its role in shaping the future of manufacturing and beyond.

What Are the Significant Developments in 3D Printing Today?

Several significant near-term and forward-looking developments are shaping the landscape of 3D printing over the next period. Examples include:

- Researchers are making the first giant strides in 3D bioprinting, with progress in printing complex tissues and organ-like structures for regenerative medicine, drug testing, and personalized healthcare. These hold out the potential for built replacement organs to become commonplace.

- There's growing interest in large-scale additive manufacturing for construction, aerospace, and automotive applications. Companies are developing novel techniques and materials for printing large structures, such as: buildings, aircraft components, and vehicle parts. Polymer-bound regolith will likely be the construction material of choice for moon construction, for example in mining Helium-3.

- The 3D printing industry is focusing on sustainability, with efforts to develop more eco-friendly materials, reduce waste, and implement recycling programs. Companies are exploring (or already marketing) bio-origin, biodegradable, and recycled materials that minimize environmental impact.

- 3D printing is becoming a cornerstone, integrated into digital manufacturing workflows across forward-looking Industry-4.0 installations, enabling on-demand production, mass customization, and distributed manufacturing networks. Advances in software, automation, and digital design tools are driving this integration, as the cost of processes/parts drops due to increased volume and material/process simplification.

- 3D printing continues to offer opportunities to revolutionize healthcare, with applications in patient-specific structural implants, surgical guides, biocompatible and organic soft tissue manufacture, and prosthetics. Innovations in medical-grade materials and bioprinting techniques hold out the prospect of near-term and rapidly improving patient outcomes and reduced healthcare costs.

These developments reflect the ongoing evolution and diversification of 3D printing technologies across a wide spectrum of technologies and approaches, with significant implications in all market sectors. As the core technologies continue to advance and diversify, 3D printing is poised to unlock new possibilities and reshape the future of manufacturing and beyond.

Did the Development of 3D Printing Technology Take Place in the Latter Half of the 20th Century?

The dream of additive manufacturing is older than the technology, but the reality of being able to convert a digital file into a real-material, printed part only became tentatively realized in the last years of the 20th century.

What Are the Other Things I Should Know About 3D Printing?

The huge and expanding range of technologies under 3D printing is astonishing so far. AI and machine learning algorithms are being integrated into 3D printing processes to optimize design, improve printing speed, and enhance material properties.

Researchers are approaching the ability to bio-print complex human tissues and organs using living cells derived from the patient. This has the potential to revolutionize regenerative medicine and organ replacement. 3D printing enables the customization of medical devices such as implants, prosthetics, and surgical tools to match individual patient anatomy. This reduces surgery times, improves treatment outcomes, and reduces recovery times.

Combining 3D printing with nanotechnology allows the creation of intricate structures at the nanoscale, enabling advancements in materials science, electronics, and drug delivery systems. This is approaching atomic scale construction, at the leading edge of research.

Furthermore, 3D printing technologies are being adapted for use in space. This enables the manufacture of tools, spare parts, and even habitats on demand during long-duration space missions. Advancements in multi-material 3D printing allow for the simultaneous deposition of a variety of materials. This enables the creation of complex structures with customizable properties built from multi-functional parts.

To learn more, see our full guide on How 3D Printers Work.

Summary

This article presented the history of 3D printing, explained it, and discussed various important milestones. To learn more about 3D printing, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Copyright and Trademark Notice

- FDM® is a registered trademark of Stratasys Inc.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.