Case Study: From Workshop to Moonshot – Xometry's Role in Intuitive Machines' Lunar Return

Learn how Xometry provided mission-critical CNC machined parts for Intuitive Machines’ lunar lander, Odysseus, helping its engineering team stay on schedule and achieve the first successful American Moon landing in over 50 years.

| Industries | Manufacturing Services Utilized | Project Brief | Solution |

|---|---|---|---|

Industries Aerospace | Manufacturing Services Utilized CNC machining | Project Brief NASA tasked Intuitive Machines with building a lunar lander, dubbed Odysseus, that would make the first successful American landing on the Moon since Apollo 17. To meet their fast-approaching deadline, they needed to source hundreds of specialized machined parts quickly. | Solution By working with Xometry, Intuitive Machines was able to source hundreds of primer-coated CNC machined parts that held the craft together as it made its descent to the lunar surface. Odysseus touched down safely, began transmitting valuable data to NASA, and helped establish a hopeful precedent for the future of commercial space exploration. |

Odysseus Sticks the (Lunar) Landing

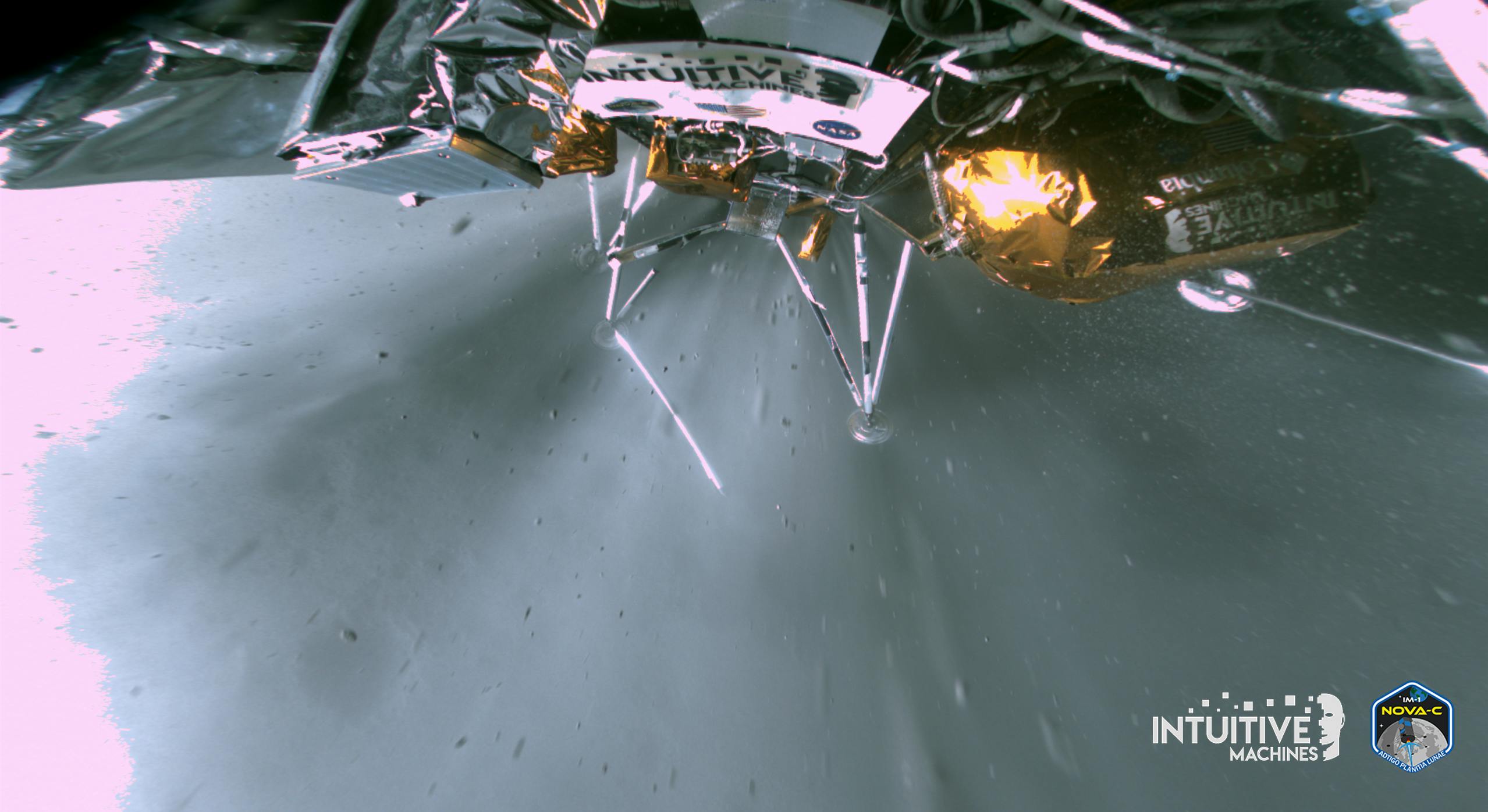

On the evening of February 22, 2024, the Intuitive Machines team waited to see if Odysseus, the lunar lander they spent years building together, had survived its harrowing journey to the Moon’s surface. “On landing day, we were all huddled up out there in the shop staring at the timer – we knew it was going be landing in a couple of minutes,” said Brandon Crain, a procurement manager for Intuitive Machines.

Intuitive Machines is a diversified space exploration company focused on pioneering the commercial landscape of outer space and is part of NASA’s Commercial Lunar Payload Services (CLPS) initiative. The science and technology payloads sent to the Moon’s surface as part of CLPS are helping lay the foundation for future human missions and a sustainable human presence on the lunar surface.

After Odysseus landed, the group continued to wait anxiously. “It's just crickets. Nothing. We're all just waiting,” Crain said. “It was like 10 minutes where we're all wondering, ‘Did it work?’”

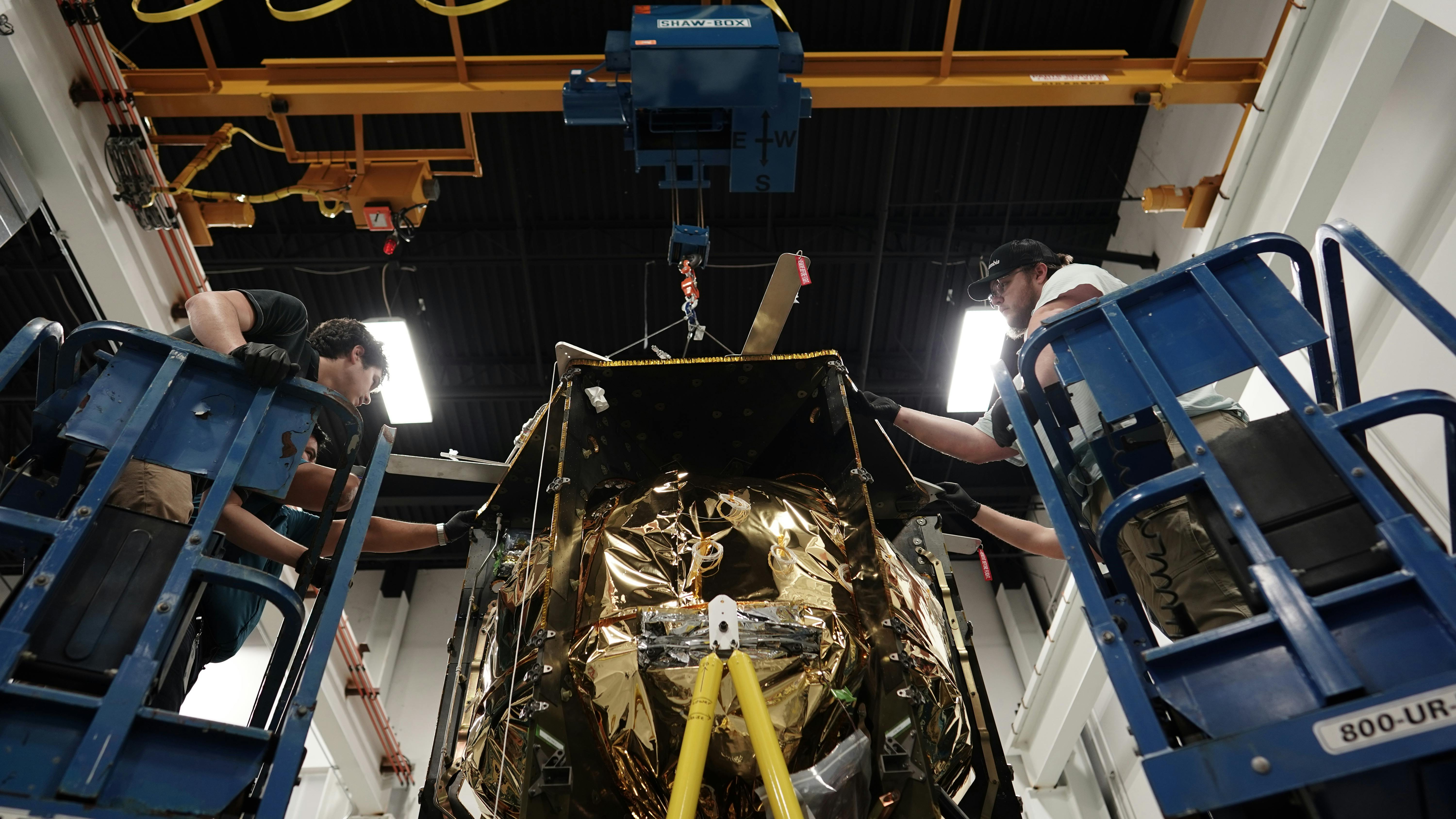

Credit: Intuitive Machines/ Nick Rios

Tim Crain (no relation), chief technology officer at Intuitive Machines, finally shared the news the team was waiting to hear “Alright, guys, we can confirm without a doubt that our hardware is on the surface of the Moon.”

The Intuitive Machines team was able to successfully land the Company’s Nova-C class lunar lander on the Moon, marking the United States’ first lunar landing since Apollo 17 more than 50 years ago.

“The minute that they could confirm that they had a signal, the place went nuts – it was amazing! Because until that minute, we didn't know [if it survived the landing],” Crain recalled, smiling. “That was a very, very fun night.”

For most, Odysseus’ journey began with a rocket launch and ended with a successful landing. For Crain and his team, that night was an exhilarating conclusion to years of hard work and dedication.

Credit: Intuitive Machines/ Nick Rios

Brandon Crain serves as a liaison between the engineering and purchasing teams at Intuitive Machines. “Once the engineers have parts they need made, they hand them off to me. I facilitate which part comes from where and I find the right vendor for each one.”

Crain first became familiar with the company by working with them as a vendor himself. When the leaders at Intuitive Machines learned of his 25 years of experience sourcing custom-machined components, they hired him as a full-time member of the team.

When Crain joined the Intuitive Machines team, he set out to refine their procurement process. The 150 engineers in his Houston-based team had grown accustomed to ordering parts on their own without going through a vendor vetting process. When looking at their vendor orders, he often asked, “Is this even something this person should be selling us? Are they qualified to make this type of part? How are they going to inspect it?” Crain said.

Thankfully, Crain knew from experiences in his previous role that he could turn to Xometry to help simplify the procurement process. “Xometry quickly helped me plug some gaps. [With Xometry], we can check boxes for inspections or rely on them if we need additional surface treatments or tight tolerances. The website for submitting quotes is super straightforward. It was an easy way for us to start fixing [these issues] and get stuff very quickly.”

Credit: Intuitive Machines/ Nick Rios

One afternoon, Crain received a phone call from Xometry’s CEO, Randy Altschuler. “He's said, ‘Hey, I’m seeing a lot of activity on your account – is there anything that you need us to work on?’ I was like, ‘Man, I'm so glad you called me.’ He put some people in place to really help streamline a lot of the issues that we were facing.”

Xometry’s applications engineering team helped Crain further streamline the process. “They understood our internal language and helped get things reliably and quickly,” he said. "Xometry’s team was diligent about referencing our internal inventory tracking numbers in their communications. By doing this, Xometry helped us track and resolve DFM issues much more efficiently – which is very helpful when you are tracking hundreds of parts among hundreds of engineers."

Credit: Intuitive Machines

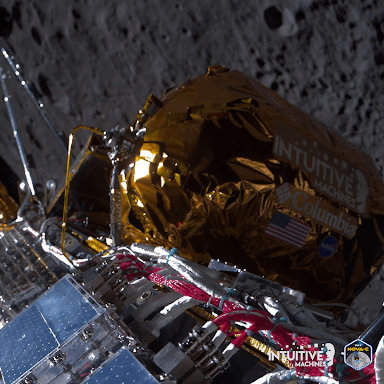

The lunar lander is encased in carbon fiber and aluminum honeycomb sandwich panels. This design makes Odysseus robust enough to withstand landing forces while remaining lightweight.

“Mass is the enemy,” Crain explained. “Because the heavier you are, the more fuel you need. The more fuel you need, the heavier you get. And so we do everything we can to be as light as possible while keeping it strong enough for its application.”

Unfortunately, while this panel design kept the design lightweight, it did create a challenge for Intuitive Machine’s engineering team. “You can't screw anything into it; It doesn't have the meat,” Crain said “And so anywhere we need a fastener like a screw or bolt, you have to put a metallic body inside of that panel.”

By placing Xomery CNC machined spool fittings on each side of the panel, Intuitive Machines’ engineering team was able to create a thread point that they could screw into. These titanium spool fittings are about an inch in diameter and are coated in a special adhesive primer, which helps the spool fasteners bind the panels together.

Credit: Intuitive Machines/ Nick Rios

“There are hundreds of those, and they're literally all over the vehicle,” Crain remarked. “[There is a] very good chance that if it got bolted onto the lander, it was bolted through a Xometry spool fastener.”

Xometry is equipped with thousands of material and surface finish options. If you don’t see what you need on our menu, that doesn’t mean Xometry can’t source it. Select “Other,” and our DFM team will get back to you with the price and lead times. Xometry will match you with a supplier that is best suited to your unique needs. In the rare circumstance where Xometry does not have immediate access to a material or finish option, it will onboard suppliers with materials or finishes you provide.

When he brought the issue to Xometry, “they took on that custom primer for us,” Crain said. “And it's been a game changer for building the first vehicle. We ordered hundreds of parts with that primer on it, and they're on the Moon right now.”

One of Crain’s favorite Xometry parts was the CNC machined landing gears designed to make first contact with the lunar surface. After ordering the custom aluminum panels that were placed on the bottom side of the landing gear, Intuitive Machines leadership etched the names of their team into them.

“Xometry made and delivered that dish. That was pretty dang cool.”

How Xometry Helps You Build Your Big Ideas

Xometry has helped thousands of engineers and procurement professionals source high-quality parts quickly. Our AI-driven platform, backed by our global 10,000+ supplier strong network, revolutionizes the procurement process, providing instant pricing and lead times for you and your team.

If you have a big idea you need built, we’d love to help. Get an instant quote today, or connect with a member of our team and discover why you can count on Xometry for your next project.

Credit: Intuitive Machines/ Carter Pytel

After successfully landing its first spacecraft, Intuitive Machines has fundamentally disrupted the economics of landing on the Moon through a fixed-price performance contract, demonstrating unprecedented economics and efficiency to commercial customers and NASA.

Intuitive Machines is now readying itself for the IM-2 mission. The commercial and NASA payloads on IM-2 complement the pursuit of water on the Moon and the effort to establish a foothold on the south pole, where NASA’s $93 billion Artemis campaign is targeting human missions this decade.

Intuitive Machines is assembling IM-2’s propulsion and structural components in-house and will be completing the integration of NASA’s ice mining drill in the fourth quarter of 2024. In addition, Intuitive Machines’ Micro Nova hopper, designed to search for water ice in permanently shaded regions of the Moon, completed thermal vacuum chamber testing before the end of the year.

Xometry is excited to support them as they embark on their next voyage into the final frontier.

To learn more about how to get the most value from our proprietary platform, be sure to watch 7 Pro Tips for Mastering Xometry’s Instant Quoting Engine®. This webinar recording is a must-listen for engineering, product design, and procurement professionals looking to leverage Xometry's platform for enhanced manufacturing efficiency.