Custom 3D Printed Jigs and Fixtures

Let Xometry 3D print jigs and fixtures for use in your production projects.

Xometry offers custom 3D printed jigs and fixtures for a variety of manufacturing applications.

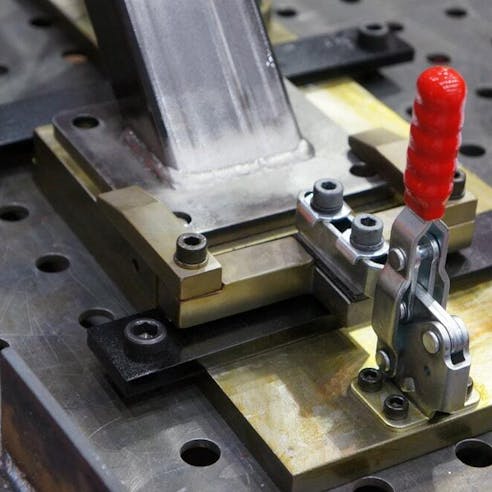

Jigs are customized tools that connect to a workpiece so that a specific fabrication process (cutting, painting, sizing, etc.) can be repeated across numerous workpieces to improve repeatability and quality. Fixtures support workpieces, securing them in a shared point of reference across workpieces. The main difference between a jig and a fixture is that a jig guides a workpiece to a stationary tool, while a fixture keeps the workpiece stationary while a tool moves to the fixed workpiece.

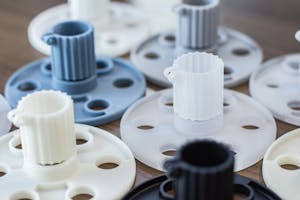

Both jigs and fixtures provide increased repeatability, accuracy, and modularity across workpieces and tools. The advent of additive manufacturing technology like 3D printing allows manufacturers to not only create more complex and contoured jigs and fixtures, but to do so at a much faster pace. 3D printed jigs and fixtures benefit from SLA, FDM, and other printing types and are commonly made out of resins, impact and heat resistant thermoplastics, electrostatically dissipative (ESD) thermoplastics, flexible plastics, and other materials.

What Are Jigs and Fixtures?

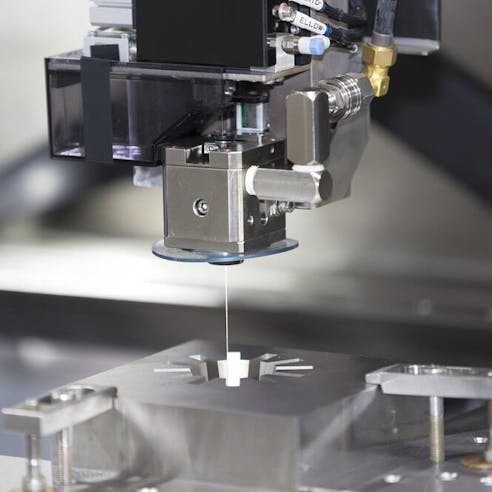

Jigs are custom-made tools used to restrict and guide a workpiece during a manufacturing process. Jigs are especially useful in cases where a complex cutting, bending, drilling, or other process is required across numerous parts and where CNC or automation is unavailable. Jigs typically connect to a part and move with it towards a stationary tool (table saw, lathe, etc.), guiding the operation to a predefined location on the piece.

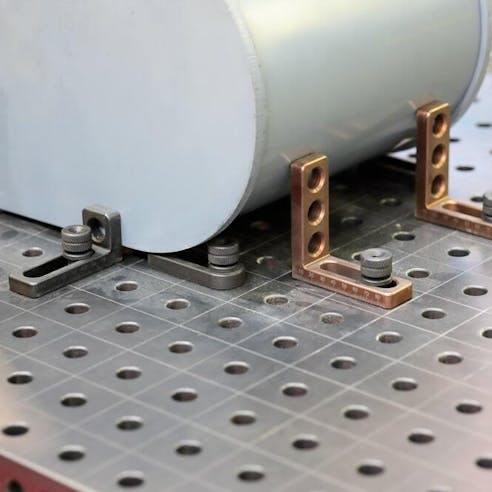

Fixtures are custom-made tools that fix a workpiece to a set, standardized location to improve repeatability and consistency across many workpieces. Fixtures are useful when supporting and locating a workpiece during operations, and provides the same datum across manufacturing runs. Fixtures do not guide the workpiece as jigs do, and typically remain stationary as a moving tool operates on the part.

Jigs and fixtures work in tandem to increase cycle time and simplify the manufacturing process, making workers both more productive and at less risk for injury. They offer a low/no error approach to performing the same operation across many parts, as the operator can only work within the restricted conditions of the jig/fixture. 3D printing adds even more flexibility in jig/fixture designs, as they can be truly custom-fit to a given application and be manufactured in a matter of hours instead of the lengthy subtractive jig/fixture fabrication process.

Advantages of 3D Printed Jigs and Fixtures

There are several key benefits to choosing 3D-printed jigs and fixtures over traditionally manufactured versions, which include:

- Improved production speed

- Reduced production cost

- Consistent part dimensions

- Increased part accuracy

Improved Production Speed

3D printed jigs and fixtures save time in two directions–they are quicker to produce, and quicker to deploy. Additive manufacturing designs can be quickly iterated on and refined, meaning that an ideal jig or fixture can be brought to the bench as fast as the printer can print (a matter of hours, or at worst a couple of days). These customized tools will also speed up manufacturing for operators, as they simplify their job and provide a near fool-proof method of handling workpieces without risk of injury or mistakes.

Reduced Production Cost

Many traditional jigs and fixtures are made out of wood or metal, and must be fabricated using adhesives, fasteners, and other material (not to mention the labor cost for designing, building, and verifying the jig/fixture). 3D printing consolidates these production costs into just the print material and the operating cost (electricity bill and sometimes a supervising technician). 3D printed jigs and fixtures are a much more economical option, both in their initial production cost and in their replacement cost (if it breaks, just print another).

Consistent Part Dimensions

3D printed jigs and fixtures allow designers to input the exact dimensions needed for their workpieces, providing consistent part dimensions across the whole manufacturing run. 3D printing materials are dimensionally stable under working conditions and offer the same repeatability as other, more expensive traditional jigs and fixtures. Using these additively manufactured tools, fabricators ensure the right work happens in the right location across workpieces, providing consistent part dimensions with little investment cost.

Increased Part Accuracy

By restricting the workpiece’s movement and guiding the tool to the correct location, jigs and fixtures increase accuracy without the need for computerized control. If CNC or other automation tools cannot be implemented, jigs and fixtures are the best method to create accurate, highly repeatable parts.

Ready to print custom 3D jigs and fixtures?

Free shipping on all US 3D printing orders

Industry Applications of Custom 3D Printed Jigs and Fixtures

The use of jigs and fixtures in production spans across industry and helps to increase precision manufacturing capabilities for a range of manufacturing applications and processes. Xometry's custom 3D printing of jigs and fixtures provides support to industries such as:

- Aerospace & Defense

- Automotive

- Consumer Products

- Electronics & Semiconductors

- Energy

- Lighting

- Medical & Dental

- Robotics

Medical Jigs and Fixtures 3D Printing

Xometry provides the manufacturing tools for custom 3D printed jigs and fixtures for the medical industry using compliant materials like PCTG, TPU, PEEK, PETG, and others. The medical industry not only has significant design specifications, but also the requirements of regulatory bodies that must be firmly adhered to. Xometry will fabricate your 3D printed jigs and fixtures with these in mind and is ISO 13485, 7, and 8 Medical Clean Room certified to ensure these requirements are exceeded.

Jigs and Fixtures for the Automotive Industry

Xometry provides the manufacturing tools for custom 3D-printed jigs and fixtures for the automotive industry. Xometry is ISO 9001 and 2768 certified to ensure accurate tolerances and compliance with the many regulatory manufacturing standards found in automotive applications. 3D printed jigs and fixtures can be made out of durable metals like tool steels, aluminum, and other alloys to ensure the high volume production runs of car manufacturing do not wear them down. Xometery’s QA Lab inspects and certifies each part before shipping, giving you peace of mind that your automotive part will not buckle under full load.

Jigs and Fixtures for the Aerospace Industry

Xometry provides the manufacturing tools for custom 3D-printed jigs and fixtures for the aerospace industry. Aerospace manufacturing must not only be highly accurate but also relies on the integrity of each part to keep users safe, meaning jigs and fixtures are an absolute necessity during manufacturing (especially with oversized parts that cannot fit in a standard CNC machine).

Xometry is AS9100 and NADCAP certified to ensure each part is built to the accreditation standards of this demanding industry and is also ITAR-compliant to comply with the even more rigorous standards of defense equipment manufacturing and exporting.

3D Printing Processes

Custom Metal 3D Printing Service

Stereolithography (SLA) 3D Printing Services

Direct Metal Laser Sintering (DMLS) 3D Printing Service

Metal Binder Jetting 3D Printing Service

Why Choose Xometry for 3D Printed Jigs and Fixtures?

Wide Range of Process and Material Options

Xometry offers a full suite of 3D printing processes and a wide selection of material choices.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

We are ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

Let Xometry create 3D-printed jigs and fixtures for your production projects

Free shipping on all US 3D printing orders