Maraging Steel 3D Printing

Get instant online quotes on custom maraging steel 3D printed parts. Free shipping on all US orders. ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified. Subject to availability. Xometry doesn't guarantee that we can provide this service at any given time.

What is Maraging Steel?

The name maraging steel is a combination of the words martensite and aging. Maraging steel has the high hardness common with martensitic steels, and the material is aged by exposing it to relatively high temperatures for extended periods in a process known as precipitation hardening. The aging process increases the tensile strength of the steel without sacrificing its ductility.

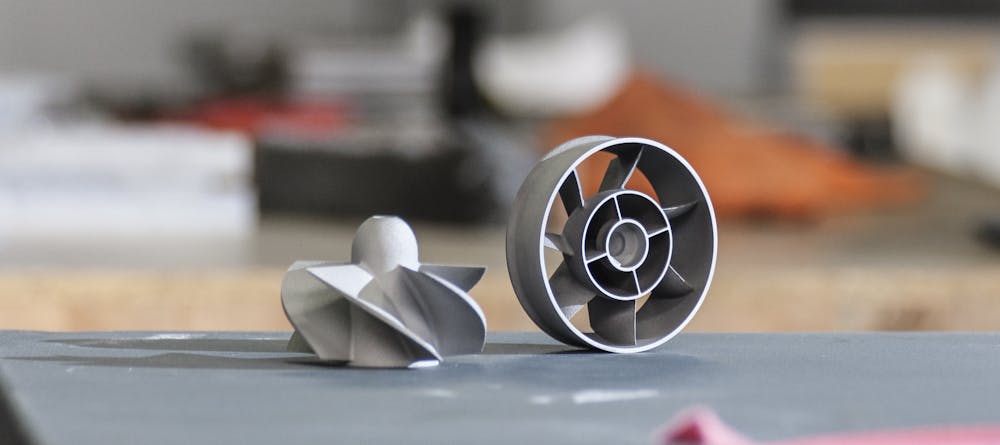

Maraging steel is a high-strength, high-hardness alloy that has very little carbon in its formulation and derives its strength from its other alloying elements. Maraging steel 3D printing allows for the creation of complex parts that are typically deployed in punishing applications found in the aerospace and automotive industries.

Maraging Steel - MS1

MS1 maraging steel is also referred to as grade 300 maraging steel. This specific alloy has the second-highest strength and hardness values out of the four common maraging steel alloys. Typical applications can include tooling, rocket motor cases, and gears.

| Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

|---|---|---|---|---|

Tensile Strength (MPa) 1200 ± 100 | Yield Strength (MPa) 1100 ± 100 | Elongation at Break (%) 12 ± 4 | Hardness (Brinell) 311 to 344 | Density (g/cm^3) 8–8.1 |

Finishes

Maraging steel 3D printing results in parts with 100% relative density and can be readily polished and machined.

Standard: The standard finish refers to the removal of any support structures. The surface of the part is also medium blasted to create a uniform appearance.

CNC Machining or Polishing: In some cases, CNC machining or polishing can be specified for specific features on the component. For example, maraging steel can be polished up to 0.5 μm. However, these additional processes are evaluated on a case-to-case basis.

Cost-saving Design Tips

To save cost when maraging steel 3D printing, follow these cost-saving design tips:

DFM: Maraging steel 3D printing can produce high-strength, high-hardness functional parts. When designing parts for metal 3D printing, make sure that any enclosed areas have holes to remove unfused powder after printing. DMLS prints generally require support structures to prevent warping as well as to support overhangs. Designs will have to take this into account. Maraging steel 3D printing can result in parts that are lighter, with fewer individual parts when compared to CNC-machined parts. In order to learn how to leverage these benefits consult with a Xometry expert.

Application: Maraging steel is an expensive alloy, and its use should be carefully considered. Most applications do not require high levels of hardness or tensile strength, other steels like 316L may be better suited.