Garolite CNC Machining

Get instant quotes on machining garolite materials with our online Garolite CNC Machining Service. Make quick turn prototypes and production parts in days with free standard shipping on all US orders. ISO 9001:2015, ISO 13485, and AS9100D certified. ITAR registered.

About Garolite CNC Machining

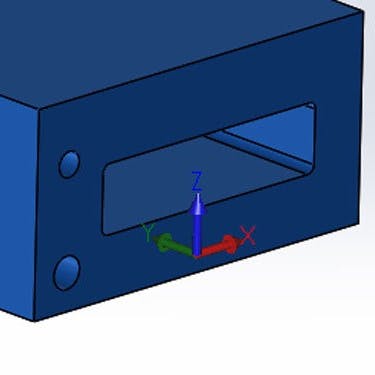

Garolite is a thermoset composite made from fiberglass and phenolic epoxy resin. As a thermoset, garolite cannot be melted and reformed. If it is heated above its peak operating temperature, it breaks down chemically and will not retain its properties once cooled. This makes injection molding in garolite impossible. CNC machining in garolite is the only method of manufacturing complex parts with this material.

Garolite is a glass-reinforced epoxy composite with a high strength-to-weight ratio and excellent corrosion and moisture resistance, making it ideal for marine applications. It is also fire-resistant and a great electrical insulator, making it a material of choice for electronic circuit board substrates.

Garolite G-10 (FR4)

CNC machining in Garolite G-10 (FR4) produces parts that are ideal for corrosive or high-moisture applications. Typically, these combinations of environmental conditions are found in the marine industry, where garolite is used for engine components such as mounting brackets and applications that require electrical insulation and mechanical strength.

Xometry offers garolite in both G-10 and G-10 FR4 grades. FR4 is a fire-retardant grade of Garolite G-10 with a flammability rating of UL94 V-0. Both grades share similar material properties except for the better flammability rating FR4 offers. In most cases, G-10 FR4 can be safely substituted when G-10 is called for; however, you should not substitute G-10 when FR4 is required.

| Tensile Strength, Yield (MPa) | Compressive Strength (MPa) | Hardness (Rockwell M) | Flammability Rating | Continous Operating Temperature (°C) |

|---|---|---|---|---|

Tensile Strength, Yield (MPa) 262-310 | Compressive Strength (MPa) 448 | Hardness (Rockwell M) 110 | Flammability Rating UL94 V-0 | Continous Operating Temperature (°C) 140 |

Garolite G11 (FR5)

Similar to G-10, garolite G-11 (FR5) is a glass-epoxy laminate material. G11 is a better thermal insulator than G10 and can withstand higher operating temperatures as a result. This makes it a great choice for mechanical or electrical applications that will be used in high-temperature environments.

| Tensile Strength, Yield (MPa) | Compressive Strength (MPa) | Hardness (Rockwell M) | Flammability Rating | Continous Operating Temperature (°C) |

|---|---|---|---|---|

Tensile Strength, Yield (MPa) 255-295 | Compressive Strength (MPa) 434 | Hardness (Rockwell M) 112 | Flammability Rating UL94 V-0 | Continous Operating Temperature (°C) 150 |

Finishes

Garolite is typically a green to yellow-green material but is also sold in black. It does not take well to polishing due to its fibrous composition. Typically, polishing its matte surface finish will not buff out to a shine.

As Machined: Garolite generally has a smooth matte finish after machining. This means that parts left in their as-machined state won’t compromise the aesthetic appeal.

Bead Blast: Parts manufactured in garolite can be bead blasted to remove any uneven surfaces produced during machining.

Cost-saving Design Tips

Garolite is a high-cost engineering plastic, and as such, it is important to limit manufacturing costs where possible.

Design to standard stock sizes: Garolite is limited to bar, rod, tube, and sheet stock. When designing parts out of this material, take care to first learn the available stock sizes, then design to meet those constraints. Less material removed to achieve the final dimensions means increased cost savings both in terms of wasted material and time spent machining. CNC machining in garolite requires diamond or superalloy tooling, so it’s an expensive material to machine.