Polypropylene (PP) CNC Machining

Get instant quotes on custom polypropylene machined parts with our Online CNC Machining Service. Make quick-turn prototypes and production parts in days with free standard shipping on all US orders. ISO 9001:2015, ISO 13485, and AS9100D certified. ITAR registered.

About Polypropylene Machining

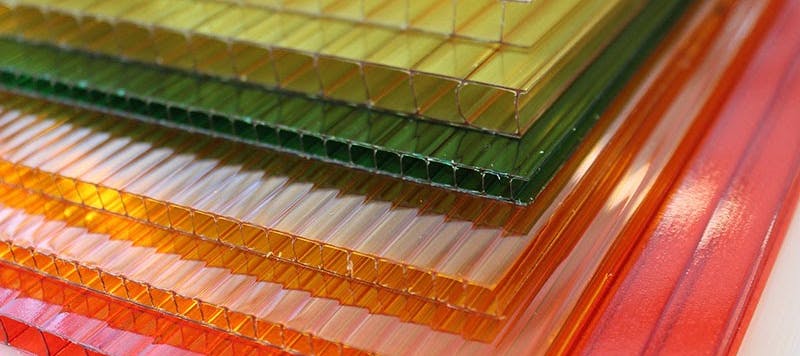

Polypropylene (PP) is a semi-crystalline thermoplastic that comes in two different forms; it can be composed of homopolymers or copolymers. Homopolymer polypropylene is the most generic grade whereas copolymer polypropylene has varying degrees of ethylene mixed into it. Machining polypropylene may be more challenging than with other common plastics due to its tendency to gall and melt. Polypropylene’s excellent chemical resistance and fatigue strength make it especially useful for flexible parts and parts that are exposed to corrosive environments.

Polypropylene (PP) is a BPA-free, lightweight plastic with exceptional fatigue resistance and toughness. These properties make it a popular material for use in a wide range of applications across the automotive, packaging, and consumer product industries.

Generic Polypropylene

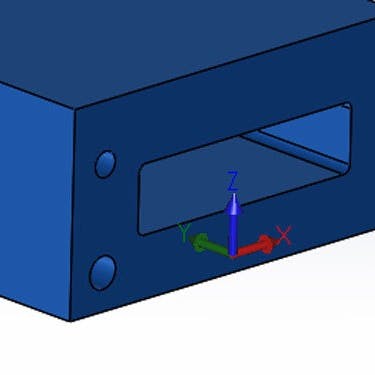

While CNC machining in polypropylene is challenging due to its tendency to gall and melt, homopolymer polypropylene offers a range of benefits for CNC machined parts. Its slick surface makes it ideal for mechanical items like gears and its fatigue resistance means that thin features such as living hinges are easy to incorporate into designs.

| Tensile Strength, Yield (MPa) | Elongation at Break (%) | Hardness (Rockwell R) | Heat Deflection Temperature (°C) | Glass Transition Temperature (°C) |

|---|---|---|---|---|

Tensile Strength, Yield (MPa) 19-45 | Elongation at Break (%) 8-750 | Hardness (Rockwell R) 49-81 | Heat Deflection Temperature (°C) 60-129 | Glass Transition Temperature (°C) 130-174 |

Finishes

Polypropylene parts are a natural off-white color. PP does not accept surface finishes like paints very well. Its hydrophobic nature also makes it very difficult to dye.

As Machined: The most common surface finishing option for anyone CNC machining in polypropylene is to simply leave the part in an as-machined state.

Bead Blast: CNC machining in polypropylene tends to leave burrs on part edges and the polypropylene easily melts when in contact with the cutting tool. This creates a sub-par surface finish that needs further sanding with coarse sandpaper or media.

Cost-saving Design Tips

CNC machining in polypropylene can be cost-effective thanks to the low cost of the material. However, reducing excessive machine and post-processing time is critical to keeping costs low. One way this can be achieved is by keeping tolerances standard for plastic and composite machining:

+/- 0.010” for features of size (length, width, height, diameter)

+/- 0.010” for location (position, concentricity, symmetry)

This is especially important because machining plastics can cause warping from the heat generated during material removal.