Acrylic Laser Cutting Service by Xometry

Upload your CAD files to get an instant quote for acrylic laser cut prototypes and production parts. No minimums. Get parts in days and free standard shipping on all US orders.

Xometry offers the highest quality custom acrylic laser cutting services for a variety of industries.

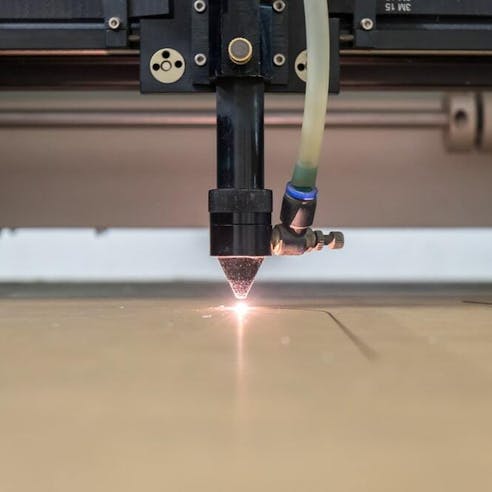

Laser cutting allows users to create complex cuts, engravings, or marks in acrylic using a laser beam within a computer numerical control (CNC) based system. Acrylic sheet can be cut into virtually any 2D shape that exactly matches your tolerances and specifications. Acrylic laser cutting offers a fast, efficient, and versatile manufacturing process for nearly any industry, and with Xometry you get access to our Manufacturing Supplier Network that provides competitive pricing, unique custom services, and additional benefits.

What is Acrylic Laser Cutting?

In laser cutting, a thin laser beam carves out parts from sheet or plate autonomously using computer numerical control (CNC). This computerized laser system cuts, engraves, or marks material as defined by the CAD design. Acrylic (also known as polymethyl methacrylate, or PMMA) is a material that performs exceptionally well when laser cut, and combined with its blend of strength and optical clarity makes it an ideal choice for laser cutting applications. To learn more about this material, see our article on Everything You Need to Know about Acrylic (PMMA). Making custom laser cut acrylic with Xometry offers an accurate, efficient, and cost-saving alternative to conventional manufacturing techniques with acrylic sheets, and increases the manufacturing capabilities of your business.

Advantages of Acrylic Laser Cutting by Xometry

- Weather Resistance & Strength-to-Weight Ratio

- Accuracy, Repeatability, and Quality

- Automated Manufacturing

- Increased Production Speed

- Instant Quotes & Free Shipping in the US

Weather Resistance & Strength-to-Weight Ratio

Acrylic laser-cut parts are exceptionally water, temperature, and impact resistant, making them an ideal choice for weather-tough environments. Acrylic is also a lightweight material with good strength characteristics, giving it a favorable strength-to-weight ratio for applications where every ounce counts.

Accuracy, Repeatability, and Quality

Laser cutting with acrylic is a highly accurate and repeatable process across many production runs. Reduce QA and verification procedures with acrylic laser cutting to prevent substandard parts and increase production volumes without impacting workflow. Also, Acrylic is by far the best plastic material to laser cut as it produces a flame-polished or frosted edge with no post-processing necessary.

Automated Manufacturing

Acrylic laser cutting is largely automated thanks to CNC control, reducing work for technicians and removing laborious manual tasks. With acrylic laser cutting, businesses can refocus time and resources to save businesses money over production runs thanks to added automation.

Increased Production Speed

Acrylic laser cutting significantly reduces the production time of parts, and allows for several unique parts to be cut at the same time, increasing the overall throughput of your manufacturing project. The quality of laser cuts also reduces post-processing steps, increasing the overall efficiency of the system.

Instant Quotes & Free Shipping in the US

Xometry offers instant pricing, lead times, and design-for-manufacturing feedback in a matter of clicks using The Xometry Instant Quoting Engine℠. This tool puts data science to work so you can easily choose the optimal price and lead time option for your project. Xometry also offers free shipping to anywhere in the US for any of our processes.

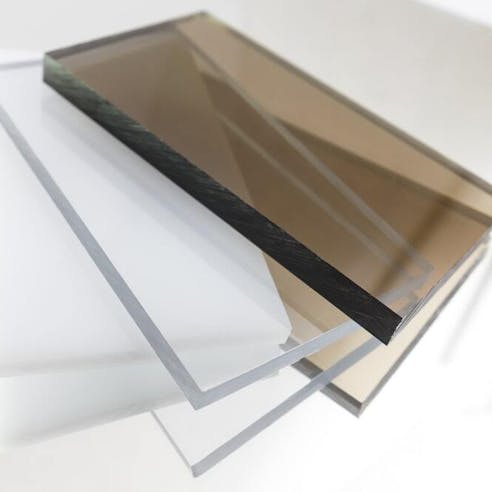

Acrylic Sheet Colors

Xometry offers laser cutting for acrylic sheets in a variety of colors, including clear and opaque options for both cast and extruded acrylic. Note that all acrylic comes in a gloss finish unless otherwise specified, and cast acrylic will have inherently better embedded clarity over extruded varieties. If you don’t see your intended material listed here, please reach out to our application engineering team and we can help source the exact material needed for your application.

- Clear Acrylic Sheet:

- Opaque Acrylic Sheet:

Clear Acrylic Sheet:

- Clear

- Clear Static-Dissipative

- Clear Fluorescent Amber

- Clear Fluorescent Blue

- Clear Fluorescent Green

- Cleat Fluorescent Red

Opaque Acrylic Sheet:

- Opaque Black

- Opaque Dark Gray

- Opaque Light Gray

- Opaque Blue

- Opaque Green

- Opaque Red

- Opaque Violet

- Opaque White

- Opaque Yellow

- Mirror

Need Acrylic Laser Cut Parts?

Acrylic Sheet Thickness

Xometry offer laser cutting for acrylic sheets in a variety of thicknesses and specifications, including:

- Clear

- Clear Fluorescent

- Opaque

- Mirror

- Static-Dissipative

| Acrylic Type | Minimum Thickness (inches) | Maximum Thickness (inches) |

|---|---|---|

Acrylic Type Clear | Minimum Thickness (inches) 0.100” | Maximum Thickness (inches) 0.254” |

Acrylic Type Clear Fluorescent | Minimum Thickness (inches) 0.095” | Maximum Thickness (inches) 0.132” |

Acrylic Type Opaque | Minimum Thickness (inches) 0.088” | Maximum Thickness (inches) 0.132” |

Acrylic Type Mirror | Minimum Thickness (inches) 0.106” | Maximum Thickness (inches) 0.130” |

Acrylic Type Static-Dissipative | Minimum Thickness (inches) 0.088” | Maximum Thickness (inches) 0.162” |

Laser Kerf Specifications at Xometry

Kerf is a term to describe material losses due to cutting. Laser kerf is the material lost from burning material with a laser. Acrylic laser cutting has kerf sizes typically less than 0.010”, which is much less than other mechanical methods. Kerf size is important for part creation as it directly impacts material wastage, restricts minimum feature sizes, and defines overall design capabilities. Acrylic laser cutting kerf sizes are small enough to reduce material inefficiencies, improve tolerances, and unlock more design freedom for the final part.

Common Project and Product Use of Acrylic Laser Cutting

Xometry's acrylic laser cutting service provides acrylic parts that are design-cut for a variety of projects and uses. Some examples of common acrylic laser cutting projects and products are below:

- Windows & Shields

- Signage & Displays

- Recreation/Protective Equipment

Windows & Shields

Clear acrylic sheet is regularly used for window applications in place of glass for its enhanced impact resistance, increased strength, and its optical clarity. Acrylic sheet is an ideal material for technologies like bulletproof glass where there is no compromise between safety and transparency. Laser cutting allows these windows and shields to be manufactured in more complex shapes that better fit the final design, and can be warped or molded post manufacturing for additional contouring.

Signage & Displays

Clear and colored acrylic sheets are commonly used for signage and display applications where weather resistance and aesthetics are a must-have. Mirrored acrylic can be used to create reflective shines or accent features that heighten appeal, and thick acrylic sheets can protect items on display from being stolen while not sacrificing viewability. Laser cutting allows designers to fit their advertising and displays to their creative intentions, and allows for custom features that aid in installation, maintenance, and longevity.

Recreation/Protective Equipment

Thin opaque acrylic sheet is commonly used in the manufacturing of recreational and protective equipment for a variety of industries. The strength-to-weight ratio of acrylic makes it ideal for helmets, padding, and other equipment pieces that are worn for long periods of time. Laser cutting acrylic for these applications adds automation into the manufacturing process, improving the part-to-part quality while also augmenting manufacturing capacity.

Alternatives to Acrylic Laser Cutting

Xometry also offers many options for alternatives to acrylic laser cutting services, including other materials and other manufacturing processes, such as:

- Acrylic CNC Machining

- Custom Waterjet Cutting

- Metal Laser Cutting

- Stereolithography (SLA) 3D Printing

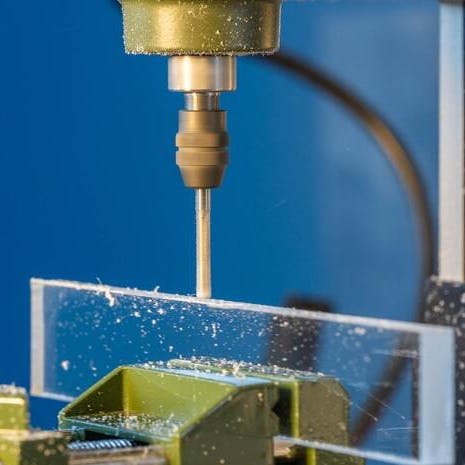

- Acrylic CNC Machining: Machining acrylic sheet with a CNC mill, while not as accurate as a laser cutting system, can offer manufacturers additional fabrication choices like embossments, angled cuts, more complex geometries, and much more. Learn more about our capabilities with our Acrylic CNC Machining capabilities page.

- Custom Waterjet Cutting: Waterjet cutting allows designers to cut much thicker acrylic while retaining the low kerf size and design freedoms of laser cutting. Waterjet cutting can also cut a much wider range of materials including those not suitable for laser cutting (including glass). Learn more about our capabilities with our Custom Waterjet Cutting Services capabilities page.

- Metal Laser Cutting: While opaque, metal has key advantages over acrylic such as strength, workability, and scientific characteristics (conductivity, antimicrobial, etc.). Metals also offer a totally unique aesthetic quality over acrylic, and can heighten a design with premium trims and polished furnishings. Learn more about our capabilities with our Custom Laser Cutting Services capabilities page.

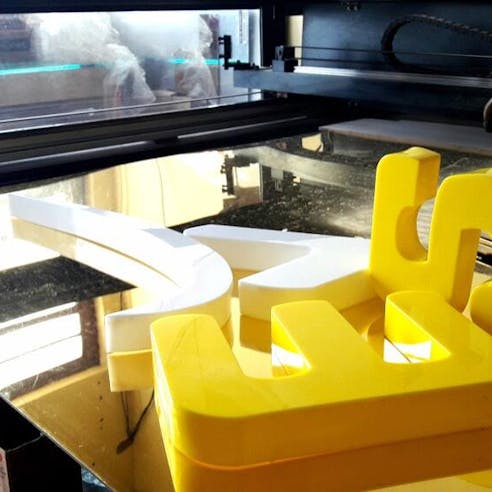

- Stereolithography (SLA) 3D Printing: If your part must be translucent but is more complex than what other acrylic techniques can achieve, SLA printing offers high-resolution prints with high-quality clear plastic alternatives. Achieve great results in as fast as a few hours by simply loading a CAD file into an SLA printer and letting it manufacture your clear part for you, no tooling necessary. Learn more about our capabilities with our Stereolithography (SLA) 3D Printing Services capabilities page.

Why Use Xometry's Acrylic Laser Cutting Services?

Endless Options

Choose from thousands of possible combinations of sheet materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.