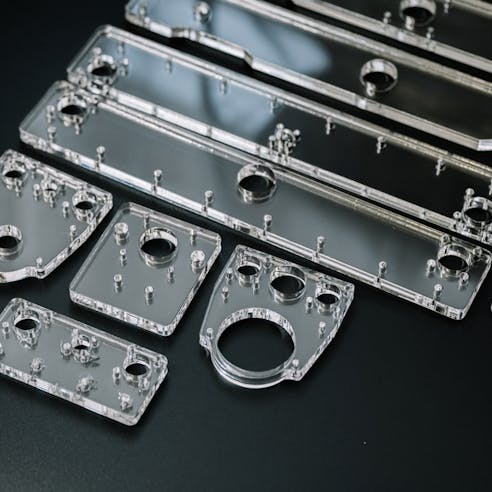

On-Demand Custom-Cut Acrylic Services

Upload your CAD files to get an instant quote for custom cut acrylic prototypes and production parts. No minimums. Get parts in days and free standard shipping on all US orders.

Acrylic is a versatile and widely used thermoplastic that is lauded for its optical clarity, versatility, light weight, strength, and durability. Xometry offers high-quality custom-cut acrylic services for a variety of industries and applications. Precision cutting processes like laser cutting, waterjet cutting, and mechanical cutting, can all be used to produce intricate acrylic designs for signage, protective barriers, display fixtures, and medical equipment. Our comprehensive industry experience, coupled with our vast manufacturing network and dedication to client satisfaction, allows high-quality custom-designed parts to be made with precision and speed.

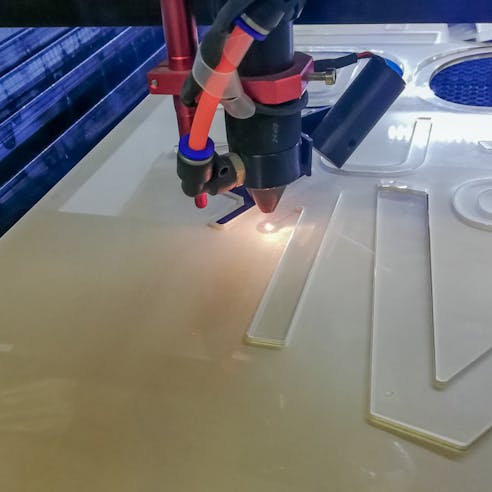

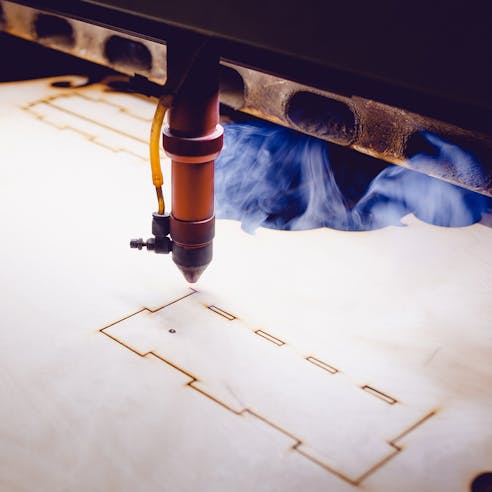

Custom-Cut Acrylic Process

The custom-cut acrylic process consists of four steps. The first step in our custom-cut acrylic process is to use CAD design to create precise templates. Templates are designed in such a way that allows repeatable fabrication of acrylic parts. Careful and meticulous design from the beginning of the process ensures that acrylic parts satisfy each requirement established by the client. Machine parameters are then established to ensure client requirements are satisfied. Regardless of whether laser cutting, waterjet cutting, or CNC machining is used for acrylic cutting, careful planning during this stage is essential to ensure successful production. Once the CAD design is complete and process parameters are established, production of the acrylic parts can begin. While the process is largely automated, attentive observation is required during this stage to ensure proper fabrication and avoid time-consuming errors. We employ post-processes like polishing and finishing to obtain the desired appearance of the part as requested. After the product has been cut and finished, a final quality inspection is conducted to ensure all client requirements are satisfied.

Material Options and Finishes for Custom-Cut Acrylic

There are many different material options and finishes when it comes to custom-cut acrylic parts. The different material options and finishes are described below:

- Clear

- Colored

- Frosted

- Mirrored

- Glossy

- Matte

- Clear: Clear acrylic is the most common type of acrylic and is ideal for applications in which transparency/visibility, and user protection, are important. Applications of clear acrylic include: windows, doors, and safety barriers like sneeze guards in restaurants or hockey rink barriers.

- Colored: Acrylic can come in many different colors. This makes it great for signage, advertisements, and decorative trim pieces in commercial, transportation, and consumer goods applications.

- Frosted: Frosted acrylic is used to create privacy screens that still allow light to pass through the material. Frosted acrylic is great for things like: shower doors, windows, and architectural accent pieces.

- Mirrored: Mirrored acrylic is a lightweight and easier-to-handle alternative to glass mirrors. Additionally, mirrored acrylic is more impact resistant and stronger than glass.

- Glossy: Glossy acrylic is great for signage since glossy surfaces can improve visual appeal and aesthetic qualities.

- Matte: Like glossy acrylic, matte acrylic is great for signage. The contrast between matte acrylic and other sheens allows for more eye-catching features and improves visual appeal.

Benefits of Custom-Cut Acrylic Services

Acrylic has numerous benefits. Utilizing Xometry’s on-demand custom-cut acrylic services ensures you can get high-quality custom acrylic parts fast. Some benefits of acrylic are listed below:

- Versatility

- Durability

- Light Weight

- Transparency

- UV Resistant

- Weather Resistance

- Impact Resistant

Versatility

When it comes to cutting acrylic, laser cutting, waterjet cutting, and mechanical cutting are all possible. Additionally, acrylic’s ability to easily be shaped and formed into different products makes it great for a wide range of applications across different industries. This enables customers to pick fabrication methods suitable for their project and budget while still being able to satisfy the requirements of their application.

Durability

Acrylic is a strong material compared to glass—up to 30x stronger! This is because acrylic is a thermoplastic with an ordered crystal structure compared to glass which has an amorphous structure. Acrylic’s ordered crystal structure means it is also more ductile and more impact resistant compared to glass. This makes acrylic great for applications like protective barriers such as: windows, doors, and anti-theft display cases.

Light Weight

Acrylic is not only stronger than glass but is also more lightweight. This makes cut acrylic parts easier to handle, transport, and install and also makes it great for applications in which weight is a concern, such as in the aerospace industry.

Transparency

Acrylic is praised for its optical clarity and ability to remain transparent over time. It does not yellow like other transparent plastics. The material is great for applications found in airplanes, residential buildings, and commercial windows, as well as sneeze guards, signs, light fixtures, lenses, and motorcycle shields.

UV Resistant

Acrylic is resistant to UV radiation and does not discolor over time like other clear plastics such as polycarbonate or PET (polyethylene terephthalate). This makes acrylic a great choice for architectural accent pieces, windows, and doors.

Weather Resistance

Acrylic parts are weather-tough materials and are resistant to water and ambient environment temperature extremes. Additionally, acrylic retains its clarity and color over time. These weather-resistant characteristics make acrylic great for outdoor applications like signage and architectural components.

Impact Resistant

Acrylic is highly impact resistant and has an impact strength that is 6 to 17 times higher than glass. This makes acrylic great for transparent, protective enclosures like windows and doors for residential and commercial applications, as well as safety enclosures for sporting or leisure venues like hockey rinks or ball fields.

Need custom cut acrylic parts?

Disadvantages of Custom-Cut Acrylic Services

There are some disadvantages to using custom-cut acrylic products. Described below are four disadvantages:

- Fragility

- Susceptibility to Scratches

- Limited Heat Resistance

- Cost

Fragility

While acrylic is durable and has high impact resistance compared to glass, it is brittle compared to other thermoplastics. Acrylic’s fragility makes its use in applications that experience frequent impact or require high strength limited.

Susceptibility to Scratches

Acrylic is highly susceptible to scratches. Scratches can create blemishes on acrylic’s surface which may ruin its aesthetic appeal. Therefore, precautions must be taken to ensure the optical clarity and surface finish of acrylic, especially for point-of-sale materials.

Limited Heat Resistance

Compared to other thermoplastics, acrylic has limited heat resistance. Other popular thermoplastics such as polycarbonate can be used in temperatures up to 140 °C while acrylic can only be used up to 90 °C. This makes acrylic unsuitable for high-temperature applications.

Cost

The cost of custom-cut acrylic services varies depending on the level of precision and appearance characteristics required. These two things ultimately dictate what manufacturing processes and finishing techniques are used to make the acrylic parts.

Applications of Custom-Cut Acrylic

Acrylic is a highly versatile material used in numerous industries and for different applications. Below are some of the applications of custom-cut acrylic parts:

- Signage

- Display Fixtures

- Point-of-Sale Materials

- Protective Barriers

- Medical Equipment

Signage

Both clear and colored acrylic are popular for use in signage and display applications due to their weather and UV resistance, impact resistance, and optical properties. Additionally, mirrored acrylic can be used to create reflective accent surfaces that improve visual appeal. Custom-cut acrylic parts can help designers tailor their acrylic parts to satisfy their advertising and visual criteria while acrylic’s light weight makes it easy to transport and install.

Display Fixtures

Acrylic is great for use in display fixtures such as: easels, display boxes, cases, and shelves. When it comes to display boxes, such as those seen in jewelry stores, acrylic sheets can protect items on display without sacrificing visibility. Custom acrylic cutting can be used to create display fixtures of many different sizes for a variety of applications.

Point-of-Sale Materials

Point-of-sale displays are product displays that are placed strategically near cash registers and retail checkouts to maximize visibility and encourage a last-minute decision to buy amongst consumers. The different types of acrylic, from clear and glossy to frosted and matte, are great for point-of-sale displays since they can be used to create attractive displays that entice consumers to purchase more products.

Protective Barriers

Clear and transparent acrylic is commonly used to create protective barriers like: retail display cases, restaurant sneeze guards, hockey rink barriers, windows, and doors. The strength and light weight of acrylic and the ease of our custom-cut acrylic services make the material great for these applications.

Medical Equipment

Custom-cut acrylic parts can be used in medical equipment for protective windows and doors for hospital rooms, medical diagnostic equipment display protection, light fixtures, and more.

Alternatives to Custom-Cut Acrylic

Acrylic may not be suitable for certain applications and projects. In that case, alternative materials can be used to satisfy requirements. Listed below are five alternatives to using custom-cut acrylic parts:

- Polycarbonate

- PETG

- PVC

- Wood

- Metal

Polycarbonate

Polycarbonate is a thermoplastic material that is available in a variety of different opacities and colors and can be considered a viable alternative to acrylic parts. It may be preferred over acrylic for applications that require high strength or use in high-temperature environments. However, against these considerable advantages, polycarbonate is more expensive and lacks the visual appeal of acrylic since it cannot be polished and also yellows over time if exposed to UV radiation for extended periods.

PETG

PETG (polyethylene terephthalate glycol) is another thermoplastic alternative to acrylic that is also available in different opacities and colors. It is stronger and more impact resistant than acrylic, but not as flexible. Additionally, PETG is safe for food use. These characteristics make PETG great for food containment, signage, and point-of-sale materials. However, the optical clarity of PETG is not as high as acrylic—clear PETG will have a slight tint compared to clear acrylic. Additionally, PETG cannot be polished like acrylic and is also more susceptible to scratches than acrylic.

PVC

PVC (polyvinyl chloride) is also a thermoplastic alternative to acrylic. Like acrylic, PVC can come in a wide range of colors and is also available in transparent finishes. PVC is strong, high-impact resistant, lightweight, and durable. Additionally, PVC is chemically inert, fire resistant, and has low permeability. These characteristics make PVC great for point-of-sale materials and protective barriers for commercial and industrial use. Though PVC is more affordable than acrylic, it may not offer the same level of optical clarity and glossiness as acrylic.

Wood

Wood lacks the capability for its surface to be manipulated but can still be considered a great alternative for acrylic parts. While it is not transparent and its surface cannot be made glossy or matte, wood can still be an attractive and visually appealing material for signage, display fixtures, and protective barriers. Additionally, wood is strong and easy to cut and process into finished parts.

Metal

Metal can be considered an alternative to acrylic if transparency is not a big concern. Like acrylic, metal can have a lustrous and glossy appearance which could make it attractive for use in signage and architectural elements. Additionally, metal is significantly stronger than acrylic which makes it great for applications like protective barriers. However, metal cut parts can be harder to fabricate than acrylic and are much more expensive compared to acrylic.

Why Use Xometry's Custom Cut Acrylic Services?

Endless Options

Choose from thousands of possible combinations of sheet materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.