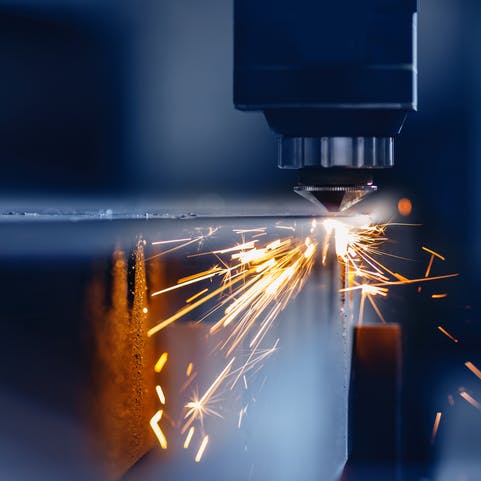

Laser Cutting Delrin® Services by Xometry

Xometry offers the highest quality Delrin® laser cutting services and can assist in the production of parts with intricate and complex geometries and excellent surface finishes.

Xometry is a leading provider of Delrin® laser cutting services. We offer high-precision cutting solutions for Delrin materials using state-of-the-art equipment and expertise. All you need to do is choose the right laser cutting, laser marking, or laser engraving process to meet your needs.

Lasers are versatile tools capable of cutting smooth edges into Delrin parts. This makes laser cutting an ideal choice for many applications, with the top three being pump and valve components, gears, and bearings. The strength, low friction, and dimensional stability of Delrin make it a reliable material for these critical components. Xometry's Delrin laser cutting services ensure the highest quality and accuracy, delivering parts that meet the strictest requirements and specifications for these industries.

What Is Delrin?

Delrin® is the brand name for a type of thermoplastic acetal resin polymer. The material, which most properly goes by the generic name polyoxymethylene (POM), was developed and patented by DuPont™ in 1956. It is known by various alternative names, including: acetal, polyacetal, and acetal homopolymer. Delrin is a high-performance engineering plastic that possesses excellent mechanical properties in terms of: strength, stiffness, and hardness. It also maintains good dimensional stability over time and has a low coefficient of friction.

When it comes to cutting Delrin, CO2 laser cutters are considered the optimal choice. They’re cheaper and easier to use than fiber optic or neodymium laser cutters. Fiber optic lasers are better for reflective materials like metals because metal absorbs their wavelengths rather than reflecting them. Neodymium lasers, on the other hand, can cut tougher and thicker materials but come at a significantly higher cost than CO2 lasers. Laser cutting Delrin with a CO2 laser operating at a 10.6-micron wavelength provides excellent results, delivering precise cuts with smooth edges.

Laser Cutting Processes With Delrin

When it comes to laser cutting Delrin, there are three main processes:

- Laser Cutting

- Laser Marking

- Laser Engraving

Laser Cutting

Delrin can be cut using a focused laser beam that traverses along a precise pre-programmed path. The laser beam melts or vaporizes the material, creating a clean and accurate cut. CO2 lasers are the most common for laser cutting Delrin because they are so effective against non-metal materials. Laser cutting machines can create intricate shapes, straight cuts, holes, and other precise geometries in Delrin.

Laser Marking

Laser marking generates permanent markings or surface color changes on the Delrin material. With the proper power and intensity, the laser beam will interact with the Delrin surface, causing a localized change in appearance. This can include darkening or discoloration of the material, creating clear and permanent markings. CO2 lasers or fiber lasers can be used to laser-mark Delrin. The two create slightly different effects on the surface.

Laser Engraving

Laser engraving Delrin is similar to laser marking but is slightly more invasive. The beam will remove layers of the Delrin material to create indentations. Usually, these take the form of patterns, designs, or text on the surface. The laser beam vaporizes or ablates the material, leaving behind a permanent engraving. Laser engraving generates precise and detailed results, making it suitable for decorative or informational designs. CO2 lasers or fiber lasers can be used for laser engraving, depending on the depth and intricacy of the engraving.

Advantages of Laser Cut Delrin

Here are some highlights when it comes to laser cutting Delrin:

- Strong

- Machinable

- Creep Resistance

- Natural Lubricity

- No Physical Contact

- Precision

- Speed and Efficiency

- Minimal Material Waste

- Automation and Reproducibility

Strong

Delrin is strong and stiff, making it suitable for applications that require structural integrity and durability. Laser cutting Delrin does not affect this property of the material.

Machinable

Delrin is known for its machinability and acceptance of tight tolerances. Some machining operations like turning or tapping screw threads can’t be accomplished with lasers, so your laser cutting operation may simply set your part up for the next machining steps.

Creep Resistance

Delrin strongly resists creep (the tendency of a material to deform gradually when under constant stress or load). Good performance in this regard ensures dimensional stability and long-term performance in applications that remain under continuous loads. Laser cutting does not affect this property of Delrin.

Natural Lubricity

Delrin has inherent lubricity, meaning it has a low coefficient of friction. This reduces the need for additional lubricants or coatings even when friction is a concern.

No Physical Contact

Laser cutting is a non-contact process, meaning there is no direct physical contact between the cutting tool and the Delrin material. This eliminates the risk of mechanical damage such as deformation or tool wear during the cutting process.

Precision

Laser cutting Delrin creates very precise and accurate results, so it will accommodate intricate designs, complex shapes, and fine details. The focused laser beam makes clean and precise cuts, resulting in high-quality finished products.

Speed and Efficiency

Laser cutting Delrin is a fast and efficient process, allowing for high production rates and quick turnaround times. It is particularly beneficial when you need to accurately and efficiently cut masses of identical or intricate parts.

Minimal Material Waste

The precision and tight computer control of the laser cutting process means it generates minimal material waste. The focused laser beam vaporizes only a minimal amount of plastic, so you get more usable Delrin from a given sheet than you would if cutting by mechanical means.

Automation and Reproducibility

Laser cutting tools can be easily integrated into automated systems, allowing for consistent and reproducible results. The use of computer numerical control (CNC) technology ensures precise and repeatable cuts, making it suitable for large-scale production.

Disadvantages of Laser Cut Delrin

While laser cutting is a great way to shape Delrin sheets, there are a few potential disadvantages to consider:

- Tends to Warp

- Bondability

- Flammability

- Heat Sensitivity

- Thermal Stress

- Charring and Discoloration

- Limited Thickness

Tends to Warp

Delrin has a tendency to warp when exposed to heat or when stored improperly. This can result in distorted or uneven parts, affecting the overall quality and functionality of the final product. Proper storage and handling techniques will minimize warping.

Bondability

Delrin is known for its incompatibility with adhesives. Relatively few adhesives will bond well with Delrin. This limitation restricts certain assembly or joining methods, pushing designers toward alternative fastening techniques such as mechanical fasteners or thermal bonding.

Flammability

Delrin is classified as a flammable material. It has a relatively low ignition temperature and can burn if exposed to an open flame or high temperatures. Adequate fire safety measures such as flame-resistant coatings or additives are often necessary if your Delrin parts may be exposed to such conditions.

Heat Sensitivity

Delrin is sensitive to heat and can degrade when exposed to elevated temperatures for extended periods. High temperatures can result in discoloration, degradation of mechanical properties, and reduced overall performance. It is important to consider the temperature limitations when using Delrin.

Thermal Stress

Laser cutting generates heat which can create thermal stress in the Delrin material. This stress can cause slight warping or distortion, especially in thin or delicate parts. It is important to optimize laser settings and cutting parameters such that they’ll minimize thermal stress.

Charring and Discoloration

Delrin is susceptible to charring and discoloration when exposed to the laser’s high temperatures. This can lead to unsightly marks or browning along the cut edges. Proper control of laser power and speed, along with air assist or other cooling methods, can help mitigate charring and discoloration.

Limited Thickness

Thin sheets of Delrin are the best targets for laser cutters. Thicker Delrin sheets may require multiple passes or more powerful lasers, which can increase processing time and costs.

In need of custom Delrin laser cutting services?

Laser-Cut Delrin Applications

Laser-cut Delrin finds use across various industries thanks to its excellent properties and versatility. Some common applications include:

- Pump & Valve Components

- Gears

- Bearings

- Water Softeners

- Rollers

- Fittings

- Robotics

- Irrigation Components

- Garden Chemical Sprayers

- Pumps & Beverage Valves

- Soap Dispensers

- Electrical and Electronics

Pump & Valve Components

Delrin's chemical resistance, low friction, and dimensional stability make it suitable for pump and valve components such as seals, diaphragms, and valve seats.

Gears

Delrin's high strength, wear resistance, and low-friction properties make it an excellent choice for teeth, gear racks, and timing pulleys.

Bearings

Delrin can be used in bearings, providing minimal friction and impressive wear resistance for smooth operation in various applications.

Water Softeners

Delrin’s resistance to moisture and chemical reactions makes it perfect for water-softener components such as valve bodies, pistons, and seals.

Rollers

Delrin's toughness, dimensional stability, and resistance to wear make it suitable for rollers in conveyors, printing machinery, and other industrial applications.

Fittings

Delrin is used in fittings and connectors due to its chemical resistance, durability, and ease with which threads and seals can be machined into the plastic.

Robotics

Delrin finds work in robotics for various components including: robot joints, gears, grippers, and structural parts. Its strength, low friction, and dimensional stability contribute to smooth and reliable robot movements.

Irrigation Components

Delrin is employed in irrigation systems for components such as: valve bodies, nozzles, and fittings. An inherent resistance to moisture and chemicals along with easy machinability are great for precise flow control.

Garden Chemical Sprayers

Delrin is used in garden chemical sprayers for nozzle components, trigger mechanisms, and seals due to its resistance to chemicals and dimensional stability.

Pumps & Beverage Valves

Delrin's resistance to moisture, chemicals, and dimensional creep makes it suitable for pump and beverage valve components, including diaphragms, seals, and valve bodies.

Soap Dispensers

Delrin is utilized in the pumps on soap dispensers, ensuring smooth and reliable flow thanks to the material’s low friction and chemical resistance.

Electrical and Electronics

Delrin is employed in: electrical connectors, insulating components, switches, relay parts, and other electrical and electronic devices. Its electrical insulation properties, moisture resistance, and dimensional stability make it an ideal choice for these applications.

Alternatives to Laser Cut Delrin

While laser cutting is a popular and effective method for shaping Delrin, there are alternative cutting processes that may occasionally suit your purposes better Some alternative Delrin cutting processes offered by Xometry include:

- CNC Milling and Turning

- Saw Cutting

- CNC Milling and Turning: Delrin can be cut using computer numerical control (CNC) milling machines. CNC milling removes material and shapes the Delrin using rotating cutting tools. The machines are versatile and precise, so they can create complex geometries and high-quality finishes.

- Saw Cutting: Delrin can be cut using jig saws, band saws, or table saws, as long as they’re equipped with blades designed for cutting plastics. Saws are suitable for straight cuts, but may not provide the same level of precision or intricacy as laser cutting or other processes.

Why Choose Xometry for Delrin Laser Cutting Services?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.