Laser-Cut Hardboard Services by Xometry

Xometry offers the highest quality laser-cut hardboard services and can assist in the production of parts with intricate and complex geometries and excellent surface finishes.

Laser-cut hardboard is a versatile material that can be used in a variety of craft and do-it-yourself projects. Hardboard is an engineered wood product made from highly compressed wood fibers. It is characterized by its high density and strength and is used extensively in the furniture, construction, and packaging industries.

Xometry is a reputable provider of laser-cut hardboard services. We offer top-notch solutions for a wide range of industries and applications. Our services utilize advanced laser cutting technology to achieve exceptional quality in cutting hardboard. At Xometry, we prioritize precision and accuracy, utilizing state-of-the-art machinery and a skilled team to deliver the best results. With our efficient processes and experienced professionals, we can provide fast turnaround times without compromising on quality.

What Is Laser-Cut Hardboard?

Hardboard, also known as high-density fiberboard, is a type of engineered wood product. It is made from compressed wood fibers that are bound together using heat, pressure, and, in some cases, a binder such as resin or wax. The process of manufacturing a hardboard involves the mechanical pulping of wood fibers and then forming them into a mat. Heat and pressure are applied to the mat to remove moisture and compress the fibers tightly together. During this process, the binder is activated, creating a cohesive and rigid material. In cases where no binder is used, the heat and the pressure are used to compress the wood fibers to form an even board. The wood fibers used in hardboard are typically obtained from hardwoods such as eucalyptus, birch, or beech.

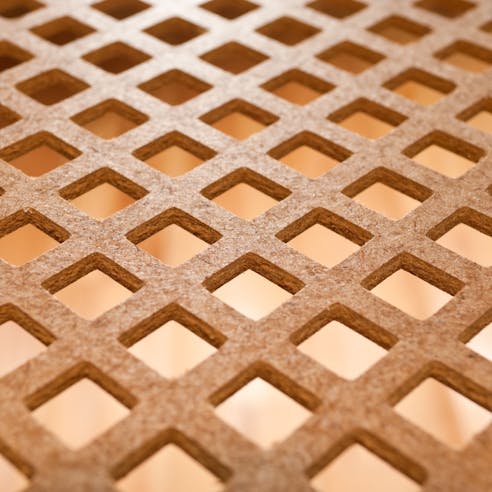

Hardboard is characterized by its high density and strength, making it a durable and versatile material. It has a smooth and uniform surface on one or both sides, depending on its intended use. The thickness of the hardboard can vary, ranging from thin sheets to thicker panels. There are different types of hardboards, including: standard, tempered, perforated, HDF, and painted. Each type of hardboard has unique properties and applications, providing a wide range of material choices based on project requirements.

Laser cutting hardboard works by directing a high-powered laser beam through a series of mirrors and lenses to focus the energy onto the hardboard surface. The intense heat generated by the laser beam vaporizes or burns away the material along the desired cutting path, resulting in clean and precise cuts.

Advantages of Laser-Cut Hardboard

Laser-cut hardboard offers several advantages, including:

- Warp Resistant

- High Strength

- Affordable

- Precision

- Versatility

- Speed and Efficiency

- Smooth Edges

- Minimal Material Waste

- Complex Designs and Intricate Details

- Reproducibility

- No Contact and Minimal Damage

Warp Resistant

Hardboard is engineered to have good dimensional stability. It is less prone to warping, fiber raising, or bending than chipboard or MDF when exposed to changes in temperature or humidity. Tempered hardboard treated with oil or tempered masonite is a good example of hardboard that has good warp resistance. However, untreated hardboard or hardboard that is not treated equally on both sides will tend to warp more. Laser cutting hardboard does not compromise the materials’ warp resistance in any way.

High Strength

Despite its lightweight nature, hardboard exhibits high strength and rigidity compared to MDF. It can withstand moderate impacts and loads, making it suitable for various applications where strength is essential. Laser cutting allows for complex interlocking designs that can further increase the strength of products made from hardboard.

Affordable

Though hardboard is typically more expensive than plywood, it is still a cost-effective option for a wide range of applications. It offers a good balance between price and performance, making it accessible for a wide range of projects and budgets. Laser cutting, being a fast and efficient cutting method only adds to the cost-effectiveness.

Precision

Laser cutting hardboard provides exceptional precision and accuracy. The focused laser beam can create clean, sharp cuts with intricate details and complex shapes. This level of precision allows for high-quality and consistent results.

Versatility

Laser cutting is a versatile process that can be used on various thicknesses (up to 15 mm in one pass) of hardboard and can cut through all types of hardboard, including standard and oil-tempered hardboard. It allows for a wide range of designs, patterns, and customization options, making it suitable for diverse applications.

Speed and Efficiency

A beam of a CO2 laser cuts through the hardboard quickly and efficiently, minimizing production cycle time and allowing for both rapid prototyping and large-scale production.

Smooth Edges

Laser cutting produces smooth, polished edges without the need for additional finishing or sanding. However, the laser cutter does leave a dark charred edge on the hardboard, and although this is mostly left as is, it can be removed through additional sanding if preferred.

Minimal Material Waste

Laser cutting is a precise and controlled process that minimizes material waste. The laser beam follows a predetermined path, optimizing the use of the hardboard and reducing material loss.

Complex Designs and Intricate Details

Laser cutting enables the creation of complex designs, intricate details, and fine engravings on hardboard. It allows for precise control over cutting depths and engraving depths, making it ideal for decorative or artistic applications.

Reproducibility

Laser cutting provides consistent and repeatable results. Once a design is programmed into the laser cutting machine, it can be reproduced accurately and efficiently, ensuring consistency across multiple pieces.

No Contact and Minimal Damage

Laser cutting is a non-contact process, which means there is no physical contact with the hardboard during the cutting process. This reduces the risk of damage, distortion, splintering, or warping that can occur with other cutting methods.

Disadvantages of Laser-Cut Hardboard

There are also some disadvantages to consider when laser cutting hardboard:

- Not Water Resistant

- Limited Thickness

- Dark Charred Edges or Burn Marks

Not Water Resistant

While some types of hardboard, such as oil-tempered hardboard, offer increased water resistance, standard hardboard is not inherently water resistant. Hardboard is susceptible to swelling, warping, and deterioration when exposed to moisture or high humidity levels. Plywood, with its layers and adhesive, provides better resistance to water damage. Laser cutting hardboard can cause the cut edges to be further exposed to moisture and water.

Limited Thickness

Laser cutting may have limitations on the thickness of the hardboard that can be effectively cut. Laser cutters can only cut hardboard up to about 15 mm thick in one pass. Thus, thicker hardboard may require multiple passes or alternative cutting methods, which can affect productivity and increase production cycle time.

Dark Charred Edges or Burn Marks

Laser cutters tend to leave burn marks or a dark charred edge on the hardboard after it has been cut. Though most people usually leave the material in its as-cut condition, the charring can be removed by sanding the edges.

Laser-Cut Hardboard Applications

Hardboard, with its versatility and durability, finds a wide range of applications in various industries and projects. Some common applications of hardboard include:

- Wall Paneling

- Flooring Protection

- Prototyping

- Lightweight Furniture

- Crafts and DIY Projects

- Packaging

- Storage

- Signage

- Children's Toys and Games

Wall Paneling

Hardboard is commonly used as a material for wall paneling. It can provide a smooth and uniform surface, adding aesthetic appeal to interior walls while also offering insulation.

Flooring Protection

Hardboard can be used as a temporary or protective covering for floors during construction or renovation projects. It helps prevent damage to existing flooring from scratches, spills, or heavy foot traffic.

Prototyping

Hardboard is often used in prototyping and model making. Its ease of cutting, shaping, and forming makes it suitable for creating mock-ups, architectural models, and prototypes in various industries.

Lightweight Furniture

Hardboard can be utilized in the construction of lightweight furniture pieces such as shelves, bookcases, and small cabinets, specifically in the non-load-bearing parts. Hardboard is commonly used as a backing material for cabinets, shelves, and storage units. It provides stability and reinforcement to furniture structures.

Crafts and DIY Projects

Hardboard is a popular choice for crafting and DIY projects. It can be easily cut, shaped, and painted. Hardboard is used for creating photo frames, signage, puzzle boards, models, stencils, and other creative crafts. It is also popular among artists for painting. Hardboard is also used as a sturdy backing material for paintings, photographs, and other artwork. It provides support and protection to the artwork.

Packaging

Hardboard is used in the packaging industry to create boxes, dividers, and protective inserts. It provides strength and protection for delicate items during shipping and handling.

Storage

Perforated hardboard, also known as pegboard, is also a popular choice for organizing tools and equipment. The evenly spaced holes allow for easy hanging and storage of tools. Hardboard can also be employed as a material for drawer bottoms, providing a smooth and sturdy surface for organizing and storing items.

Signage

Hardboard serves as a substrate for many types of signs, including indoor and outdoor signage. It can be easily painted, laminated, or printed on to display graphics, logos, or information.

Children's Toys and Games

Hardboard is utilized in the production of various children's toys, games, and puzzles. Its durability and versatility make it suitable for creating interactive and educational play items.

In need of custom hardboard laser cutting services?

Alternatives to Laser Cut Hardboard

If you're looking for alternatives to the laser cutting of hardboard, here are some other services offered by Xometry that can be used instead:

- CNC Routing

- Jigsaw or Scroll Saw

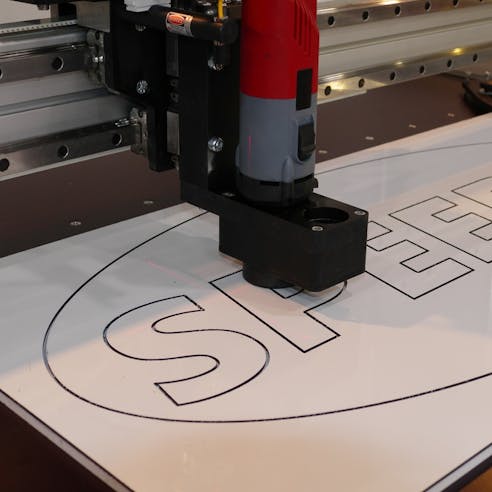

- CNC Router: A CNC (computer numerical control) router can be used to cut and shape a hardboard. It operates by using a computer-controlled cutting tool to precisely carve out the desired shapes.

- Jigsaw or Scroll Saw: A jigsaw or scroll saw can be used to cut hardboard. The main difference between these two tools is that a jigsaw is a handheld manual tool, while the scroll saw is not. These tools allow for intricate and curved cuts, although they may not provide the same level of precision as laser cutting.

Why Choose Xometry for Hardboard Laser Cutting Services?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.