Stainless Steel Laser Cutting Services by Xometry

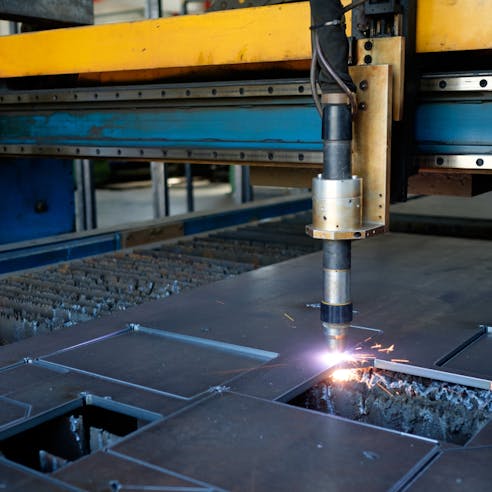

Xometry offers the highest quality stainless steel laser cutting services and can assist in the production of parts with intricate and complex geometries and excellent surface finishes.

Stainless steel laser cutting is the process of cutting stainless steel with a highly focused beam of electromagnetic energy. Many different grades and types of stainless steel can easily be laser cut, so long as the proper laser-cutting settings and tools are used. There are three main types of stainless steel: austenitic, ferritic, and martensitic stainless steel. These can be further subdivided into stainless steel grades.

Xometry offers exceptional stainless steel laser cutting services for a variety of industries — from medical to architecture and machinery, to automotive and food processing. Laser-cutting stainless steel processes have numerous advantages, including: highly precise and accurate parts, quick turnaround, environmentally friendly processes, and versatility.

What Is Stainless Steel Laser Cutting?

Stainless steel laser cutting is the process of cutting stainless steel with a highly concentrated beam of light, or electromagnetic energy. In this non-contact cutting process, the collimated beam of light, known as a laser, transfers large amounts of energy to the workpiece to rapidly heat and vaporize it away. Electrical discharges and a series of optics generate the high-powered laser, while computer programming directs the movement of the laser head. For stainless steel, fiber lasers, or lasers that are generated by doped optical fibers charged with light, are typically used for laser cutting. Energy from the laser is focused on diameters as small as 0.0125”, enabling rapid material removal while CNC G-code enables highly precise dimensions to be obtained. When it comes to stainless steel, laser cutting is one of the most precise and efficient fabrication methods for workpieces up to 20 mm in thickness.

Types of Stainless Steel

There are three types of stainless steel that differ based on their chemical compositions and preparation methods. The types of stainless steel are described in more detail below:

- Austenitic

- Ferritic

- Martensitic

Austenitic

Austenitic stainless steel is the most common type of stainless steel and has a chemical composition consisting of 16-26% chromium and up to 35% nickel. Out of the 3 types of stainless steel, austenitic stainless steel offers the highest corrosion resistance. Additionally, austenitic stainless steels are tough and ductile, which enables them to be work-hardened to various degrees. Examples of austenitic stainless steels include 304 and 316 — two of the most commonly used grades of stainless steel. These materials are used in everything from surgical and dental instruments to automotive parts to kitchen appliances.

Ferritic

Ferritic stainless steels are the second most common type of stainless steel. They are characterized by their magnetic properties and ability to be hardened by cold working. Ferritic stainless steels have a carbon content in between austenitic and ferritic types (between 0.12-0.20%). This composition makes the ferritic stainless steels hard, but mechanically weaker than both austenitic and martensitic types. Additionally, the percentage of chromium in ferritic stainless steel is lower (10.5-27%) which gives it corrosion resistance properties between that of the other types of stainless steel.

Still, ferritic stainless steels have high strength and great corrosion resistance compared to carbon steel, which makes them great for applications that are not too demanding. Popular ferritic stainless steel grades include 430 and 434. This type of steel is commonly used in trim for automobiles and architectural applications.

Martensitic

Martensitic stainless steels are the least commonly used type of stainless steel and are characterized by their high hardness. Martensitic stainless steels have varying hardness due to their high concentrations of martensitic phase depending on how they are heat treated. This type of stainless steel is available in a range of carbon concentrations from 0.1% to 1.2%. In general, martensitic stainless steels are less tough than austenitic-type stainless steels and also exhibit lower corrosion resistance. Their lack of austenitic microstructure and lower nickel content allows martensitic stainless steels to be more machinable than the other types and exhibit lower work hardening capability.

Stainless Steel Laser Cutting Advantages

The advantages of stainless steel laser cutting are listed and described in more detail below:

- Affordable

- High Accuracy

- Environmentally Friendly

- Highly Versatile

- Optimal Speed

Affordable

Compared to other 2D–cutting methods, such as waterjet cutting or flame cutting, laser cutting stainless steel is highly affordable. This is because the level of precision attainable with laser cutting, coupled with its reliability and repeatability, makes the process more cost-effective than other manufacturing methods. Waterjet cutting is simply more expensive while flame cutting may require significant post-processing to obtain finished parts.

High Accuracy

Stainless steel laser cutting can achieve part dimensions as precise as +0.0004” (0.1 mm) Because laser cutting is a non-contact cutting process, there is no chance for the part to mechanically deform and work harden. Additionally, while laser cutting is a thermal process, minimal heat is applied to the part as a whole, since the electromagnetic energy is focused on a diameter as small as 0.0125” — leading to minimal thermal distortion.

Environmentally Friendly

Stainless steel laser cutting is more environmentally friendly than other manufacturing processes such as machining or plasma cutting. Stainless steel laser cutting produces far less waste than machining since manufacturers can utilize more stock material to make parts. Over time, stainless steel laser cutting also consumes less energy than machining since laser cutting processes are fast and produce highly precise parts.

Highly Versatile

The same laser cutting setup can be used to cut a variety of different shapes, unlike other manufacturing processes that require tool exchanges to complete different types of cuts. The same laser cutting machine can also be used to cut varying thicknesses of stainless steel workpieces or be used to etch and engrave parts. These two traits make stainless steel laser cutting a highly versatile process.

Optimal Speed

Stainless steel laser cutting is an automated CNC process that requires little human intervention to be successful. The fact that the process is largely automated and that the workpiece materials are rapidly heated to vaporization temperatures, makes stainless steel laser cutting much faster than other processes, such as: CNC machining, plasma cutting, and flame cutting — especially when completing complex cuts.

Stainless Steel Laser Cutting Disadvantages

Stainless steel laser cutting is not without its disadvantages. Some of these disadvantages are described below:

- High Initial Investment Required

- Limited Material Thickness

- Material Discoloration

- Requires Technical Expertise

High Initial Investment Required

The upfront costs for laser cutting machines suitable for cutting stainless steel, or any metal for that matter, are high. This can prove to be a barrier for small to medium-sized manufacturers, as laser cutting machines suitable for stainless steel cutting and industrial use can easily top $100,000.

Limited Material Thickness

The material thicknesses with which stainless steel laser cutting can be used are limited due to the fundamental principles underlying laser light generation. After a coherent light beam is generated in the machine, a series of mirrors and a focusing lens are used to concentrate the laser light at a precise point. However, lasers diverge as they travel through space. Therefore, thicker materials present more opportunities for laser light to diverge from the original tightly focused beam, making it difficult to laser-cut thicker materials. While multiple passes can be used to cut thicker materials, this reduces the overall efficiency of laser cutting. Laser cutting is best used for stainless steel workpieces under 20 mm in thickness.

Material Discoloration

Improper stainless steel laser cutting can discolor the workpiece along the cut edges. The discoloration is usually due to slow cutting speeds that can cause excessive heat build-up and leads to oxidation of the stainless steel workpiece surface. Consequently, post-processing is required to attain a uniform surface appearance.

Requires Technical Expertise

Stainless steel laser cutting requires technical expertise to determine the best type of laser and optimal settings to achieve the best results. A person well-versed in both the theory behind how lasers are generated and how laser cutting affects different materials is essential. Additionally, improper settings can not only lead to defective parts and significant post-processing but can also damage the laser-cutting machine itself.

In need of custom stainless steel laser cutting services?

Stainless Steel Laser Cutting Applications

Stainless steel laser cutting is used in numerous industries. Some typical stainless steel laser cutting applications are listed and described below:

- Medical Components

- Automotive Components

- Appliances

- Food Processing Equipment

- Construction

- Kitchen Utensils

- Hardware

- Blades

- Machinery

Medical Components

Laser cutting is often used to make stainless steel components for medical devices and instruments. Components in medical diagnostic machinery such as: X-ray and MRI machines, pacemakers, prosthetics, and surgical and dental instruments are often made by laser cutting. The precision offered by laser cutting, coupled with its high repeatability, ensures that safe and effective medical components and devices are easily accessible to the public.

Automotive Components

Laser cutting can be used to make stainless steel automotive components such as sprockets, chassis and frame components, and more.

Appliances

Stainless steel laser cutting is used to produce parts for kitchen appliances such as brackets, plates, and exterior cover panels.

Food Processing Equipment

Machinery components for food processing equipment like mixers can be made from laser cutting. Components like exterior cover panels, mixing blades, slicers, and more are commonly made from stainless steel laser cutting due to the precision, speed, and affordability offered by the process.

Construction

Construction is an industry where stainless steel laser cutting is intermittently used. The process is used to make decorative trim pieces and facades to improve the aesthetic appeal of homes, businesses, and offices.

Kitchen Utensils

Kitchen utensils such as cutlery, ladles, tongs, spatulas, and more are often made from stainless steel laser cutting. Laser cutting is used for kitchen utensils to obtain intricate designs and customized engravings.

Hardware

Hardware commonly used for building and construction, like brackets and washers, can be made from stainless steel laser cutting. Holes in L-brackets can also be easily made by laser cutting.

Blades

Blades for a variety of industries such as food processing, agriculture, manufacturing, and more can easily be made by stainless steel laser cutting. Laser cutting is commonly used for the fabrication of blades since high precision can ensure blades are shaped and ready for use.

Machinery

Machinery components such as: gears, sprockets, brackets, link arms, and more can be made from stainless steel laser cutting. These components’ features are all predominantly in a 2D frame making them perfect for laser cutting. Moreover, laser cutting ensures that these parts are made to precise dimensions to ensure that overall assemblies fit together seamlessly.

Alternatives to Stainless Steel Laser Cutting

There are many alternatives to stainless steel laser cutting if laser cutting is not viable. The alternatives to stainless steel laser cutting are listed and described below:

- Plasma Cutting

- Waterjet Cutting

- Flame Cutting

- Plasma Cutting: Plasma cutting is a manufacturing process that utilizes an accelerated and controlled stream of hot, electrically charged particles, called “plasma,” to remove material from the workpiece surface. Plasma cutting can be used to cut through thicker pieces of metal and is cheaper than laser cutting, but cannot make cuts with the same level of accuracy as a laser cutter. Unlike laser cutting, significant post-processing is required to make presentable parts since cut edges produced by plasma cutting are rough and require grinding to obtain desired dimensions.

- Waterjet Cutting: Waterjet cutting utilizes high-pressure water (up to 60,000 psi) to cut through the material. Abrasives like garnet can be added to enhance the process’s cutting capability. While a waterjet can cut workpiece thicknesses as thick as those that can be cut with a laser, its precision is not as good. Waterjet cutting can achieve dimensional tolerances as precise as +0.02” while laser cutting can achieve dimensions as precise as +0.0004”.

- Flame Cutting: Like laser cutting, flame cutting is a thermal process. However, it uses the heat generated by a gas-fueled flame rather than a laser to cut parts. High-pressure oxygen is used to blow molten metal away and create a cavity to cause rapid oxidation and melting away of workpiece material during flame cutting. Flame cutting is perhaps the most cost-effective alternative to laser cutting, especially when cutting thick materials. However, flame cutting is a slower process and does not offer the same level of precision as laser cutting. Additionally, flame-cutting use is limited only to ferrous metals.

Why Choose Xometry for Stainless Steel Laser Cutting Services?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.