Vapor Smoothing 3D Printed Parts

Xometry’s vapor smoothing service provides low-cost finishing for additive-manufactured parts, resulting in a surface finish that rivals injection molding.

Vapor Smoothing 3D Printed Parts

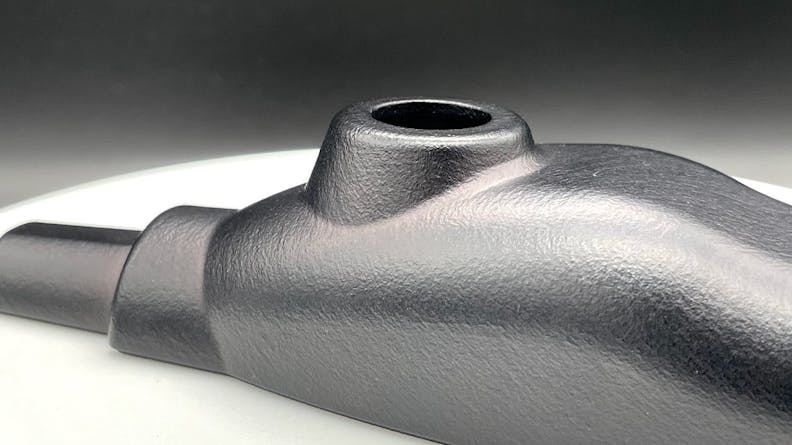

3D printing is one of the best ways to get low-volume production goods. However, plastic 3D printing tends to have one significant trade-off: parts with coarse surface finishes. Powder bed fusion processes like selective laser sintering (SLS) and HP Multi Jet Fusion (MJF) leave a matte, sugar cube-like surface finish. Fused deposition modeling (FDM) shows distinct layer lines. For the last 30 years, post-process surface finishing like abrasive media tumbling, hand finishing, or coatings have minorly improved the surface finishes of 3D printed parts. If cosmetics are a priority, engineers may choose other processes entirely like injection molding, machining, or urethane cast parts.

With the introduction of chemical vapor smoothing, a technology that smooths the surface of 3D prints and enhances mechanical performance via vaporized solvents, 3D printed plastics are now more suitable than ever for low-volume production. This process works on most 3D printed polymers and elastomers, including over twenty 3D printing materials available through Xometry. Read on to learn more about chemical vapor smoothing, its benefits, and its applications.

What Is Chemical Vapor Smoothing?

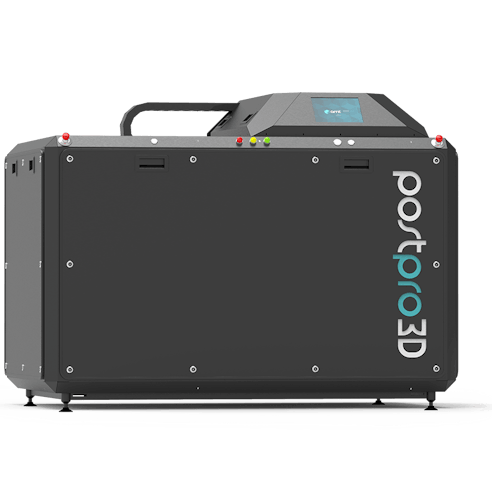

Xometry has adopted AMT’s PostPro3D chemical vapor smoothing technology. Unlike physical smoothing processes such as sanding or media tumbling, vapor smoothing does not remove material on the workpiece. Instead, a vapor finishing agent (FA 326) is introduced into a sealed processing chamber with the parts. Although the finishing agent is the same, different processing parameters are used for different materials and geometric features. Parts are racked, or hung, in a 600 x 400 x 400 mm chamber to maximize the surface exposure to the vapor. The vapor clings to the part surface where it creates a controlled chemical melt. This melt reduces the surface peaks and valleys by liquifying and redistributing material and evening the surface. The melt also has the effect of enhancing shine.

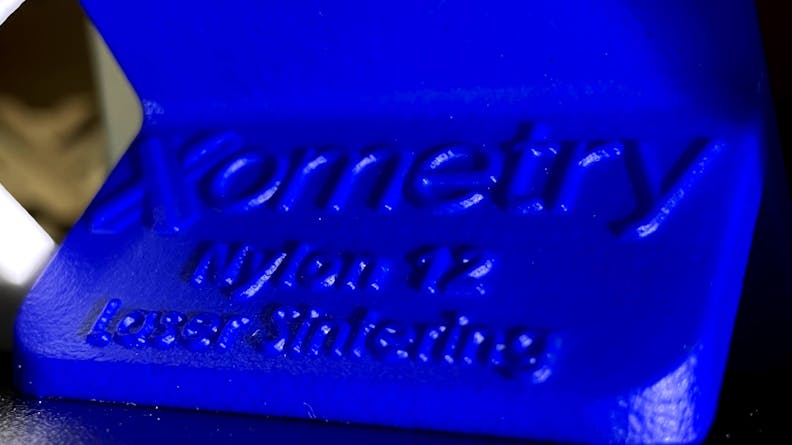

Once the parts are finished, the chamber is heated to evacuate the finishing agent to a collection vat. No residue is left on the parts. Smoothed parts are then ready for shipping or another secondary process such as dyeing.

What 3D Printed Materials Can Be Vapor Smoothed?

| Material Name | Process | Quoting Process |

|---|---|---|

Material Name Nylon 12 | Process SLS, HP MJF | Quoting Process Instant Quote |

Material Name Nylon 12, Glass Bead | Process SLS, HP MJF | Quoting Process Instant Quote |

Material Name Nylon 11 | Process HP MJF | Quoting Process Instant Quote |

Material Name Thermoplastic Urethane, TPU 88A | Process HP MJF | Quoting Process Instant Quote |

Material Name Polypropylene (PP) | Process HP MJF | Quoting Process Requires Review |

Material Name Nylon 11 EX | Process SLS | Quoting Process Requires Review |

Material Name Nylon 12, Carbon-Filled (CF) | Process SLS | Quoting Process Requires Review |

Material Name Nylon 12, Aluminum-Filled (AF) | Process SLS | Quoting Process Requires Review |

Material Name Nylon 12, Mineral-Filled (HST) | Process SLS | Quoting Process Requires Review |

The table above shows every Xometry material vapor smoothed, including those that may require a manual review. You can instantly quote select materials by choosing "Vapor Smoothing" under the "Finishes" drop-down menu.

How Much Does Vapor Smoothing Cost?

You can get instant pricing and lead times on vapor smoothing in the Xometry Instant Quoting Engine® based on the process, material, quantity, and part geometry for the most popular HP MJF and SLS materials. Because the process is batch-based, costs are relatively low per part and will decrease with increased order volumes. Xometry typically adds between 1-5 business days to lead times for vapor smoothing.

Xometry will manually review vapor smoothing orders for specialty materials like SLS high-performance blends, Nylon 11 EX, Nylon 12 AF, Nylon 12 HST, and Nylon 12 CF. Please select "Other" as your finish option and submit the quote for an expert review.

The Benefits of Vapor Smoothed 3D Prints

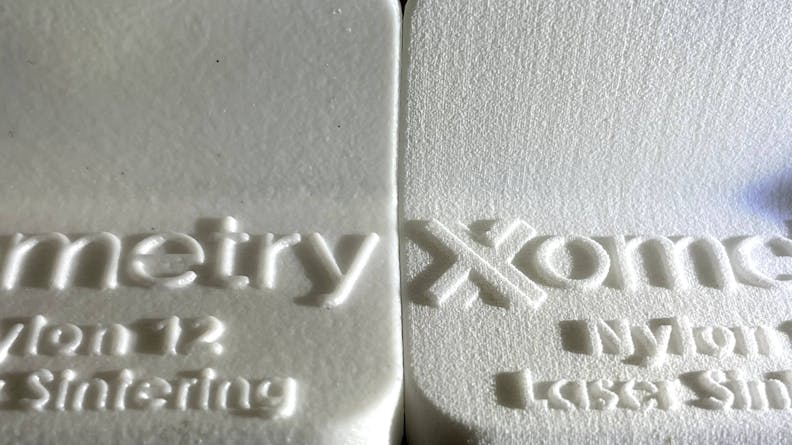

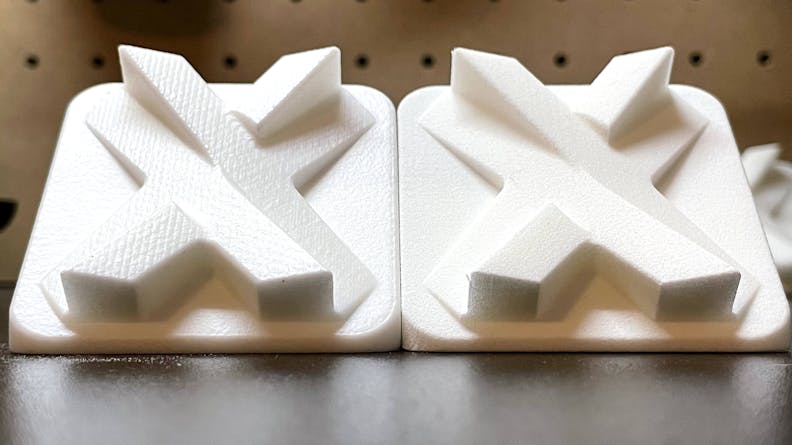

Vapor smoothed parts have improved cosmetics and are comparable to injection molding surface finishes. Standard SLS parts typically have a surface roughness greater than 250uin Ra, but with chemical vapor polishing can improve to below 125uin Ra and as low as 40uin Ra. In some studies, chemical vapor smoothing improved material surfaces by 800%-1000%. It is important to note that chemical vapor smoothing re-distributes surface material to provide a sealed, smooth surface but it does not create a polished surface. There will still be visible surface topology and minimal layer lines.

Chemical vapor smoothing can significantly increase the viability of 3D prints in food processing, medical devices, and consumer products, and is recommended for end-use applications in these industries. Notably, vapor-smoothed nylon 12 3D prints effectively reduce bacterial attachment and growth compared to standard nylon 12 3D prints. Studies have shown that vapor-smoothed SLS and HP MJF parts conform to and pass multiple biocompatibility and safety tests.

Other benefits of chemical vapor smoothing include:

- A uniform, sealed surface, on 3D printed parts

- Improved tensile, elongation, and flexural performance

- No extra coatings; the surface is the part's material

- Significantly reduced moisture absorption

- Closed loop, repeatable processing results

- Ability to polish non-line-of-sight features

- Retains features and dimensional accuracy

- No residual chemicals or media in features

- Improved cosmetics and enhanced colors

Surface roughness of chemical vapor smoothed SLS part (left) next to a standard finish part (right)

Chemical Vapor Smoothing for Health and Safety Products

| Test | Results | Details | Normative Reference |

|---|---|---|---|

Test Food Contact Test | Results PASS | Details SLS printed PA-12 parts chemically vapor smoothed with PostPro3D does not affect the consumer health nor influence the quality of food. | Normative Reference According to regulation |

Test Skin Irritation Test | Results PASS | Details SLS printed PA-12 parts chemically | Normative Reference ISO 10993-10 (2013); |

Test Cytotoxicity Test | Results PASS | Details MJF printed PA-12 parts chemically | Normative Reference ISO 10993-5 (2009); |

Test Microbiological Test on MRSA Bacteria | Results PASS | Details MJF printed PA-12 parts chemically vapor smoothed with PostPro3D show a reduction of bacterial growth quantified as 99.88% against MRSA | Normative Reference MOD ISO 22196: 2011 |

Test Microbiological Test on E. coli Bacteria | Results PASS | Details MJF printed PA- 12 parts chemically | Normative Reference MOD ISO 22196: 2011 |

The chemical used for vapor polishing is safe and the closed-loop process of AMT’s PostPro3D system ensures that there is no extra residue left on the parts after smoothing. In fact, studies have shown that vapor-smoothed SLS and HP MJF parts conform to and pass multiple biocompatibility and safety tests concerning food contact, skin irritation, cytotoxicity, and bacterial growth. The results are summarized above and more details can be found in this AMT PostPro3D document on safety certifications.

Design Tips for Vapor Smoothing 3D Prints

- Add radii to sharp internal corners to prevent rounded voids

- Keep wall and feature thicknesses above 0.040" (1 mm) to avoid distortion or defects

- Keep wall thicknesses uniform, similar to injection molding

- Be mindful that orientation-specific build lines may still be present, but smoothed

- Racking marks may be visible depending on how the work was held during processing

- Flexible materials, like TPU 88A, may have more surface imperfections versus rigid materials

On-demand Webinar: Everything You Need to Know about Vapor Smoothing 3D Prints

Understanding and Preventing Vapor Smoothing Defects

Applications for Vapor Smoothing

Concept Models

Enhanced cosmetics, better coloration, and sealed surfaces can make vapor smoothed 3D prints showstoppers.

Rapid Prototyping

Vapor smoothing does not significantly increase lead times, allowing for highly functional parts in record times.

Direct Digital Manufacturing

3D printing vapor smoothing is a bulk finishing process, making it an ideal way to build large quantities of customized parts.

Get Started on Your 3D Printing Quote

Free shipping available for domestic 3D printing orders ; learn more!

Why Choose Xometry for 3D Printing Services?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.