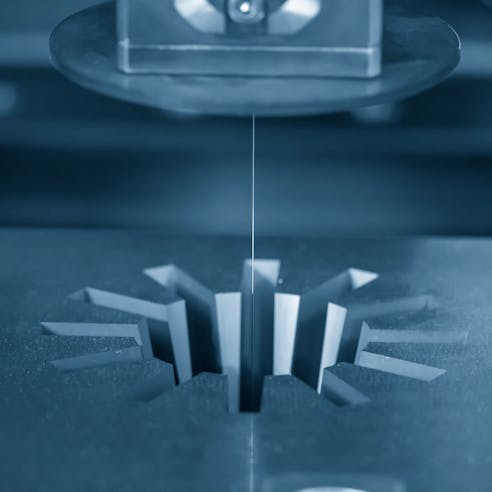

Wire EDM Machining Service

High-quality wire EDM parts with free shipping in the US. ISO 9001:2015, AS9100D, IATF 16949:2016 & ISO 13485 certified.

Custom Wire EDM Machining With Xometry

Xometry makes high-quality wire EDM parts in days, not months. Our network includes hundreds of shops with wire EDM capabilities, giving you nearly infinite capacity to make simple and complex parts.

Wire EDM (also called Electrical Discharge Machining) uses a thin single strand of wire, which is fed through the piece or part along with deionized water. The wire is spooled between two guide rollers which are guided by the computers that drive the machine. The process uses electric current to cut away conductive materials from the part and leave behind a smooth surface that does not require post-processing. Though the process is complex, Xometry's suppliers, including ITAR registered, ISO 9001:2015, ISO 13485:2016, IATF 16949:2016 and AS9100D facilities are highly skilled and can get the job done.

Other CNC Machining Services From Xometry

Custom Online CNC Machining Services

Custom CNC Milling Services

CNC Turning Service

Wire EDM Machining Finishes Available

Standard Finish (as-milled)

The finish option with the quickest turnaround. Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. Surface finish is comparable to 125 uin Ra finish.

Bead Blast

The part surface is left with a smooth, matte appearance.

Tumbled

This is a batch-based process that tumbles vibrating media to remove sharp edges and burrs on machined parts. Tumbling can remove machine marks on exterior surfaces. Parts over 8” may require a manual review.

Anodized (Type II or Type III)

Type II (MIL-A-8625/MIL-PRF-8625, Type II) creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and is usually associated with aluminum. Type III (MIL-A-8625/MIL-PRF-8625, Type III, Class 1/2 "hardcoat") is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

Titanium Anodize

A surface finish for titanium per AMS-2488 Type 2 specification. Also called Tiodize, this finish increases fatigue strength and the wear resistance of a part. Titanium anodized parts are common in aerospace and medical device manufacturing. Non-pigmented titanium anodize finishes will dull shine.

PTFE Impregnated Hard Anodize

A hard coat anodize process that embeds PTFE to create a self-lubricating, dry contact surface with Type 3 hard coat’s protective properties. This finish can be used on aluminum alloys or titanium and increases the service life of the product. This finish conforms to the AMS-2482 Type 1 Hard Coat Anodizing with Teflon (Non-Dyed).

Chem Film

Provides corrosion resistance and good conductivity properties. Can be used as a base for paint. Can leave surface yellow/gold. Adds very little thickness, about 0.00001”-0.00004”. Chem film will conform to MIL-DTL-5541, TYPE I/II.

Passivation

Improves corrosion resistance for 200 and 300 series and precipitation hardened corrosion-resistant steels. Thickness is negligible, about 0.0000001”. Conforms to ASTM A967, AMS-QQ-P-35, MIL-STD-171, ASTM A380, or AMS 2700.

Powder Coat

This is a process where powdered paint is sprayed onto a part that is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic.

Electropolishing

An electrochemical process cleans steel parts to reduce corrosion and improve appearance, by making the metal brighter. Removes about 0.0001”-0.0025” of the metal. Conforms to ASTM B912-02.

Electroless Nickel Plating

Provides uniform nickel coating which offers protection from corrosion, oxidation, and wear on irregular surfaces. The finished part will be brighter. Thickness starts at .0001”. Conforms to MIL-C-26074.

Silver Plating

Silver offers high solderability and electrical conductivity but is susceptible to tarnish. Conforms to AMS QQ-S-365D. Thickness is about 0.00002” - 0.0003.”

Gold Plating

Gold Plating provides good corrosion and tarnish resistance with excellent solderability. Default application specification is MIL-G-45204 and ASTM B488, CLASS 00, 0, OR 1. Thickness is about 0.00002" - 0.00005."

Zinc Plating

Provides uniform zinc coating which offers protection from corrosion, oxidation, and wear on irregular surfaces. Conforms to ASTM B633-15.

Ready to get started on your wire EDM machining project?

Free shipping available for domestic CNC orders ; learn more!