Navigating the Tool Library and Tool Detail Pages

Learn how to view and track the status of your tooling for injection molding, extrusion, stamping, and die casting.

So You've Requested an Injection Molding, Stamping, Casting, or Extrusion Project. Now What?

Formative processes like injection molding differ from direct manufacturing like CNC machining or additive manufacturing because they require tools. A custom-manufactured tool or die enables parts to be produced rapidly, consistently, cheaply, and at scale. Tooling is necessary for injection molding, die casting, plastic or metal extrusion, stamping, and other production-viable processes.

Xometry's AI-driven Instant Quoting Engine® makes it easy to upload your 3D file and request a product made in various tooled processes. Once your quote is requested, our team will create tooling line items that can be tracked via your Tool Library and Tool Detail pages. This page will guide you on navigating the Tool Library and the steps outlined on the Tool Detail page.

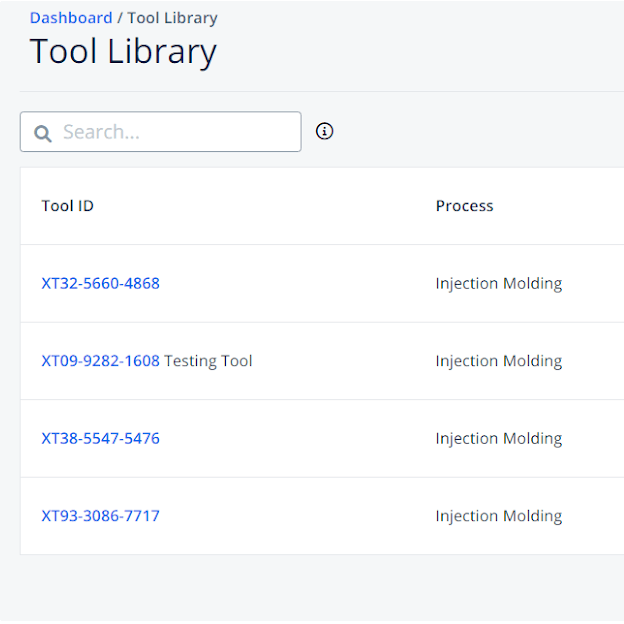

Navigating the Tool Library

Everyone with an Xometry customer account has a Tool Library. You can access this from your Dashboard by clicking Account > Tool Library. Any active tools will show on this page; the Search Bar is handy for finding projects. Clicking the three dots on the right of the the tool line item will give you the option to Edit Tool Name for extra customization. You will be able to see the following information from your Tool Library:

- Tool ID with Name

- The Process the Tool is Designed Towards

- The Status of the Tool

- Parts Orderd from that Tool

- When the Tool was Created

- The Tool Owner (Customer)

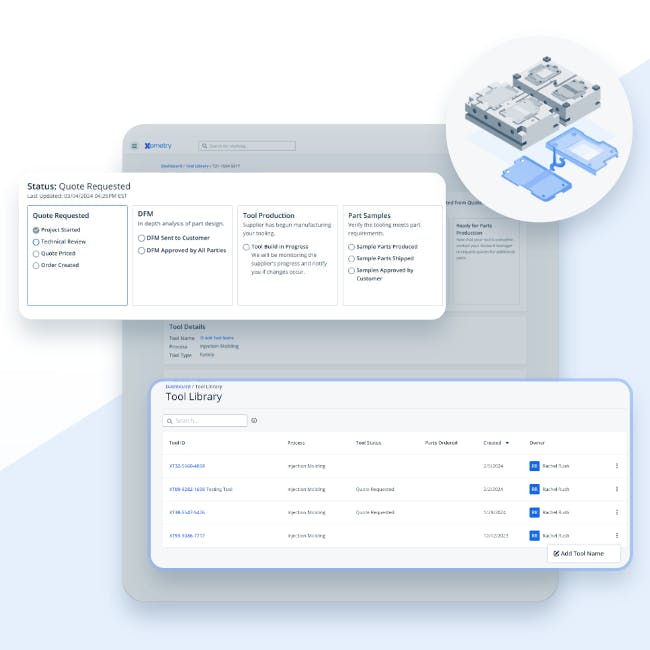

Tool Details: A Digital Toolmaking Workflow

From your Tool Library, you can click on an individual tool to find its Tool Details page. This page identifies the status of your tool, what quotes and orders it applies to, and the next steps needed before the tool is ready for part production.

The Tool Details Page consists of three sections:

- Status: This outlines major project milestones for both pre- and post-sale. This includes initial quoting through getting your first parts in hand.

- Tool Details: Details of the tool, including a section to customize its name, the Xometry Tool ID, and what type of tool, such as a single cavity, family tool, multi-cavity, etc.

- Your Activity: A filterable summary of every quote and order that contains a part associated with this tool.

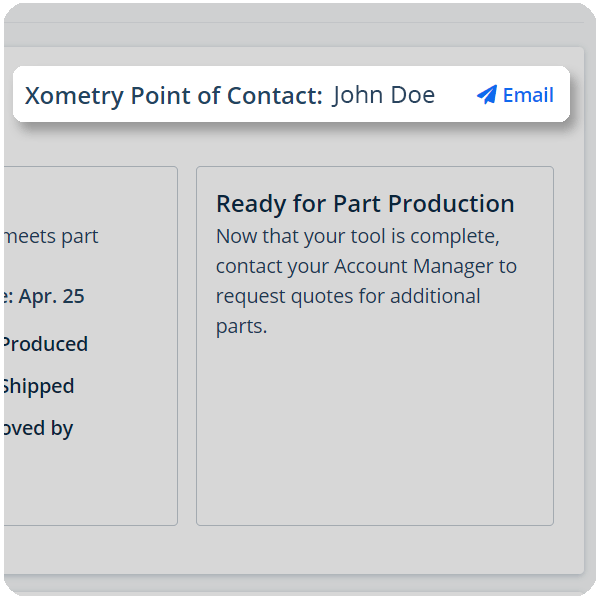

Your Point of Contact

Throughout the course of your tooling project, you may find it necessary to get in touch with us. To streamline communication, we've incorporated a Xometry Point of Contact field conveniently located in the upper right corner. This feature not only provides you with the contact's name but also enables you to initiate contact with a simple click. As your tool production progresses, the optimal contact point may evolve. Be assured that the displayed contact information will dynamically update to ensure you're always connected with the right person for your project's current phase. This ensures you have clarity on who to reach out to at any given moment.

Tool Detail Status

- Quote Requested: Pre-sale activities and the initial order.

- DFM: Design for manufacturability, tooling strategy, revision updates, and tooling kickoff.

- Tool Production: The manufacture of your custom tooling to your specifications.

- Part Samples: Initial samples, called T1s, are shipped for your review and approval.

- Ready for Part Production: Your tool is complete and can produce your part orders and future reorders.

Ready to Build Your Next Big Idea?

Tool Status Breakdown

Project Started

A manual quote request has been submitted. After reviewing your request, Xometry has created a Tool Details page so you can view and manage your project.

Technical Review

Xometry's Solutions Engineers have reviewed the project and are providing preliminary feedback. This can include consultative calls, design for manufacturing (DFM) feedback, and adjusting the quote scope based on additional feedback.

Quote Priced

Based on the initial quote and technical review the Xometry team will supply and updated quote ready for purchase. Often these quotes assume some design change will occur post-order as more in-depth DFM is presented at kick-off.

Order Created

Xometry receives an order for the tool.

DFM

Xometry works to build a comprehensive DFM analysis as well as tooling strategy to present to the customer. This is the initial kickoff and it is common to receive updated designs from the customer based on the feedback provided.

DFM Approved by All Parties

The part revision and tooling strategy is locked in after an explicit approval between the customer, Supplier, and Xometry.

Tool Build in Progress

The tooling or die(s) are being manufactured.

Sample Parts Produced

The first good parts off the tool are produced and evaluated. These are often called "T1s" and do not count toward the total order amount. If this is an injection mold that requires texturing the samples may be made untextured; the texture being applied after the samples are approved.

Sample Parts Shipped

T1s or additional samples are shipped to the customer for review and approval.

Samples Approved by Customer

Customer reviews and approves the samples allowing for part production. If required, additional finishes like texturing can be applied to the tool.

Ready for Part Production

The tool is complete and will be queued for producing the first production run as well as subsequent production orders.

Xometry's Tooled Processes

Custom Plastic Injection Molding Service

Metal Stamping Services

Metal Extrusion Services

FAQ About Tool Library and Tool Details

Check out our FAQ for Tracking Status of Molded and Tooled Projects to learn more about Xometry's Tool Library and Tool Details features. Still have questions? Contact us and we'll be happy to help.