Quality Assurance

ISO 9001:2015, ISO 13485:2016, IATF 16949:2016, and AS9100D certified | ISO 2768 compliant | ITAR Registered | CMMC Level 2

Job One at Xometry Is Making Your Custom Parts to Your Specifications

Xometry is ISO 9001:2015, ISO 13485:2016, AS9100D certified, ISO 2768 compliant, CMMC Level 2, and ITAR-registered. Our Manufacturing Supplier Network's seamless integration, the in-house applications engineering team, and the Xometry Quality Assurance Lab enable us to back every part we ship. Our Quality Assurance Lab's professionally trained quality engineering team continuously improves the part certification documentation process and our virtual inspection process to bring you peace of mind on every single order. We are experts in metrology.

Certifications to Meet Your Need

Xometry is ISO 9001:2015, ISO 13485:2016, IATF 16949:2016, and AS9100D certified, ISO 2768 compliant, CMMC Level 2, and ITAR-registered. Our diverse manufacturing suppliers have the certifications you require.

- ITAR

- ISO 9001

- AS9100

- ISO 13485

- UL

- ISO 7 and 8 Medical Clean Room

- NADCAP

- IATF 16949

- CMMC Level 2

Inspection Services

Xometry inspects your parts to the degree that your projects require. Again, you can have it your way.

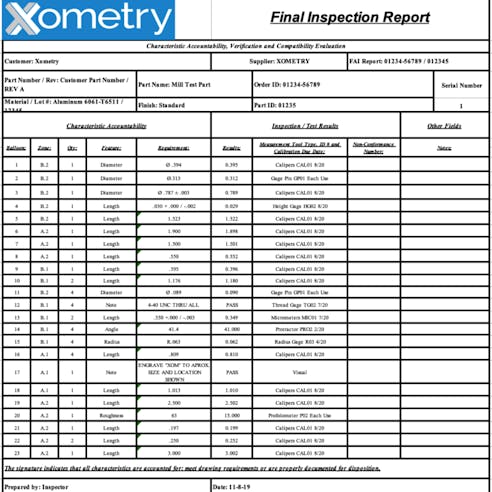

- Standard Inspection

- Standard Inspection with Dimensional Report

- CMM Inspection with Dimensional Report

- First Article Inspection Report (per AS9102)

- Source Inspection

- Additive Part Inspections

- Custom Inspection: Choose this option if your part requires other inspection requirements such as, but not limited to, the following: non-destructive testing, serialization, custom sampling plan, or if you would like to provide your own inspection datasheet.

State-of-the-art Equipment

Xometry and the facilities in our Manufacturing Supplier Network have the latest equipment to perform inspections your way.

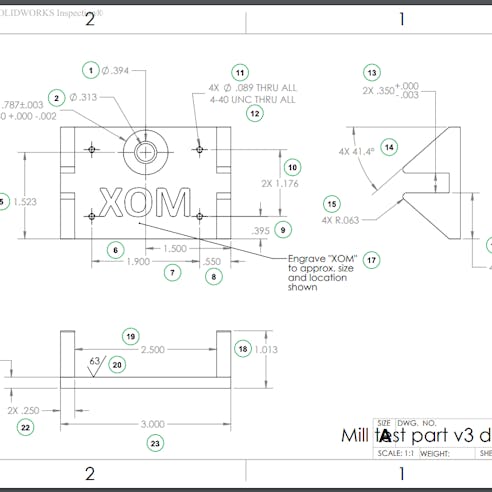

- In-line CAD stations for our technicians

- Part drawing creation to your datum schemes

- Measuring equipment certification programs

- Coordinate measurement machine (CMM) from Hexagon Metrology (Browne and Sharpe), Zeiss, Nikon, and Mitutoyo

- Shadowgraph devices

- Mass spectrometer (XRF) to validate material compositions

- Ring and thread gauges

- Gage blocks and gage pins

- Assortment of micrometers and calipers

Xometry - A Leader in Quality

You will receive thorough and timely communication from our team of quality engineering professionals. Examples include design feature confirmation, tolerance and datum scheme confirmation, design value optimization (VA/VE), sharing of key quality documents, and more. With high-precision industrial manufacturing, a variety of finishes on solid metal or plastic parts, and our quality assurance capabilities, Xometry strives to make your custom parts to your specifications. See our service agreement for more details.

Experience It For Yourself

All uploads are secure.