Formal Additive Inspection is Now Supported

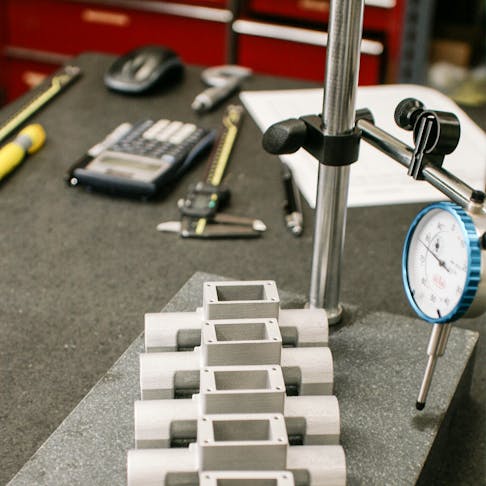

You can now request a formal inspection with a dimensional report for your additive manufacturing projects! This new offering, similar to inspection options for CNC and sheet metal parts, will produce a formal report that will ship with your order. This report will showcase measurement data on critical features defined by your provided drawing.

This new inspection option pairs perfectly with 3D-printed end-use parts and parts with quality management system requirements such as ISO 9001, AS9100D, and ISO 13485.

What 3D Printing Processes can have a Formal Inspection?

Formal inspection, as well as the option to select custom inspection reports, is available for the following additive processes:

- Selective Laser Sintering (SLS)

- HP Multi Jet Fusion (MJF)

- Carbon Digital Light Synthesis (DLS)

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- Direct Metal Laser Sintering (DMLS)

At Xometry, all parts receive a standard inspection at no additional charge. The table below shows the differences between selecting Standard Inspection or Formal Inspection with Dimensional Report.

What is the Difference Between Standard and Formal 3D Printing Inspection?

| Standard Inspection | Formal Inspection with a Dimensional Report | |

|---|---|---|

Standard Inspection Instantly quoted? | Formal Inspection with a Dimensional Report ✔️ | ✔️ |

Standard Inspection Visual check for features and finish? | Formal Inspection with a Dimensional Report ✔️ | ✔️ |

Standard Inspection Dimensional inspection to drawing? | Formal Inspection with a Dimensional Report -- | ✔️ |

Standard Inspection Inspection report provided in shipment? | Formal Inspection with a Dimensional Report -- | ✔️ |

To learn more about Xometry’s inspection and sampling plans, click here.