Is 3D Printing Food-Safe?

3D printing has matured as a manufacturing technology over the past decade, inching closer to becoming a mainstream manufacturing technology. This is in large part because 3D printing technology has gotten more sophisticated, leading to more consistent, durable, and complex prints that match its counterparts made with injection molding and CNC machining.

With this continued acceptance, more industries are exploring the use of 3D printing as a part of their manufacturing strategy. One of these is the food industry, where food packaging, utensils, or spare parts for food production lines can all become important 3D printed parts. The food industry has strict regulations regarding safety which must be considered when planning on using a new manufacturing technology. This article will discuss how to design and implement food-safe 3D printing and clarify the responsibilities of the client and manufacturer when it comes to ensuring the printed parts meet strict requirements.

What Makes a Part Food Safe?

In order to make a part food-safe, it is important to review the relevant regulations in the region where the part is to be distributed or used. This section will focus on the challenges of implementing food-safe 3D printing by basing the analysis on the 3-A Sanitary Standards that were developed to help companies comply with FDA and USDA regulations. In general, there are three factors that determine if a part is safe for use with food: its design, the materials used, and the manufacturing process.

1. Food-Safe 3D Printing Design

In terms of food safety, parts are divided into two categories according to the 3-A Sanitary Standards:

- Product Contact Surfaces - “Essentially any part surface which is exposed to the product as well as any surface onto which other food material can splash or drain onto the product.” In short, any surface of the part that can contact food.

- Non-Product Contact Surfaces - “Any part surface that does not come into contact with the product or areas such as structural supports or other external components.” In short, this is any surface of the part that does not contact food.

When evaluating a component for food-safe 3D-printing, it is important to focus on the product contact surfaces. Listed below are some key points that need to be considered in the design phase.

- Free of Crevices or Voids - Parts should not be designed with crevices or voids. This will create areas that cannot be adequately cleaned, and thus will allow bacterial growth. If these types of voids are necessary for the item’s functionality, the areas should be easily accessible when the device is disassembled so that they can be cleaned regularly.

- Smooth Corners and Radii - It is important to eliminate any sharp corners in a design and instead use large-radius fillets wherever practical. Sharp corners are difficult to clean and should therefore be avoided.

- Robustness - Food-grade parts must be robust enough to withstand their intended application without breaking down, corroding, or cracking. Each of these failure modes can introduce areas for bacteria to grow. In general, 3D printed parts and materials can withstand corrosion and breakdown if designed correctly.

2. Additive Materials for Food Safe 3D Printing

Another critical factor in determining the food safety of parts is the material. Listed below are some key material-specific factors that product designers should consider.

- Non-contaminating and Non-toxic - The base material, plus any post-processing additives like dyes or coatings, must be food safe. In terms of 3D printed plastics, it is possible for the bulk material to be food-safe initially, but get rendered unsafe by pigments and other additives. It is important to consult the Material Safety Data Sheet (MSDS) for everything that will go into the item.

- Corrosion-Resistant - A key factor in maintaining a smooth and clean surface is choosing an inert material or one that is resistant to corrosion. Some examples of corrosion-resistant materials for food-safe 3D printing include plastics such as polycarbonate or polypropylene, and metals like stainless steel. A corroded surface can become a breeding ground for bacteria because it is more difficult to adequately clean. Cleaning chemicals must also be considered.

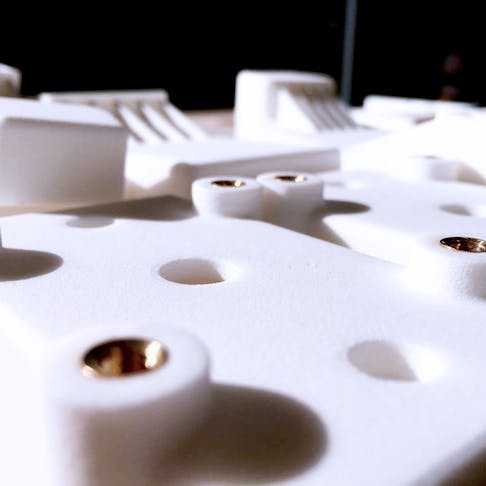

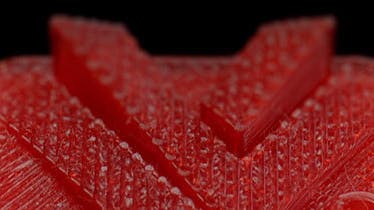

- Smooth, Non-porous, and Non-absorbant - A surface profile of 32 Ra or better should be achieved for food-safe 3D printed products. Most 3D-printing technologies build parts up layer by layer. Each of these layers interfaces to generate microscopic crevices into which food products can collect and promote dangerous bacterial growth. Porous and absorbent materials are difficult to clean and therefore promote bacteria growth. This is one of the largest challenges with food-safe 3D printing, and often requires post-process polishing or food-safe coatings to create a non-porous, smooth surface.

Which 3D Printed Materials are Sterilizable?

It is important to understand that sterilizable does not necessarily mean food-safe. Sterilizable simply means that the material can be effectively purged of all bacteria. However, the factors mentioned above can determine whether the part is ultimately food-safe. An example of this in the list below is ABS; while it is sterilizable it is not food-safe. Listed below is a summary of various sterilizable 3D printed materials.

| Process | Material | Method of Sterilization | Considerations |

|---|---|---|---|

Process SLS / HP MJF | Material Nylon 11 or 12 | Method of Sterilization Chemical, EtO, Gamma, Plasma, Chemica, Steam Autoclave | Considerations Moisture absorption, matte surface |

Process FDM | Material ABS-M30i | Method of Sterilization EtO, Gamma | Considerations Gaps and crevices in surface |

Process FDM | Material PC-ISO | Method of Sterilization EtO, Gamma | Considerations Gaps and crevices in surface |

Process FDM | Material ULTEM | Method of Sterilization EtO, Gamma, Steam Autoclave | Considerations Gaps and crevices in surface |

Process Carbon DLS | Material CE, EPX, RPU | Method of Sterilization Electron Beam Irradiation, EtO, Gamma, Steam Autoclave | Considerations Limited cycles or minor changes in mechanical properties |

Process Carbon DLS | Material FPU, EPU, SIL | Method of Sterilization Electron Beam Irradiation, Gamma | Considerations Limited cycles or minor changes in mechanical properties |

Process DMLS | Material Stainless Steel 17-4PH or 316L | Method of Sterilization Chemical, EtO, Gamma, Plasma, Chemica, Steam Autoclave | Considerations Matte surface |

List of Sterilizable Materials

3. Manufacturing Technology

The manufacturing technique and process also need to be carefully chosen when trying to achieve food-safe 3D printing. Below are two considerations for choosing the right 3D printing process:

3D Printing Technology - It is important to choose the correct 3D printing technology for the project at hand. Generally speaking, fused deposition modeling (FDM) machines will create parts with rougher surface finishes whereas stereolithography (SLA) and selective laser sintering (SLS) can create smoother surfaces. However, these decisions need to be made in tandem with material selection, part design, and post-processing surface finishes, which we discuss in the next section.

Materials of the 3D Printer- If the material being printed is rated as food-safe and the surface profile of the correct smoothness achieved, a part can still be denied its food-safe classification if the machine on which it is printed is not food-safe. An example of this would be a brass nozzle on an FDM machine that may contain traces of lead or lubricants used for the mechanical components that are not food-safe.

Video: Additive Manufacturing in the Food Industry (3-A SSI Virtual Education Program, 2021)

Which Surface Finishes Can Make a 3D Printed Part Food Safe?

As-machined 3D-printed parts may have surface finishes with a roughness that does not meet the minimum 32 Ra surface roughness standard set by the 3-A Sanitary Standards. To help surface finishes achieve a surface smoothness that does not contain small pockets for bacteria growth and that can be easily cleaned, a part can undergo post-processes like mechanical finishing and surface coatings.

FDM Surface Finish

Mechanical and Chemical Finishing

To reduce the surface roughness of parts intended for food use, it is possible to use mechanical methods to smooth out certain materials. While metal parts respond well to polishing, some plastics can be ground, tumbled, or machined to improve their surfaces.

- Grinding - Abrasive wheels can be used to remove material and smooth surfaces. However, this is not ideal for complex geometries because grinding can only access cylindrical or planar areas.

- Tumbling - Tumbling can be used as a method of smoothing parts. However, similar to grinding, complex internal geometries are not well-suited to this method since internal corners and other features may be inaccessible to the abrasive media.

- Machining - Machining can be used on both plastic- and metal-printed parts to create smooth surfaces. While this is an option, this may not be practical or economical to scale and often does not work well for thin-walled parts.

- Polishing - Various methods of polishing can be used to smooth metallic parts. Polishing can be done as a manual process using progressive sanding techniques or via electropolishing (for metals).

- Vapor Smoothing - This process can be used to smooth some plastic parts by exposing them to solvent vapor. External edges and features will chemically melt and re-seal creating a smoother surface. The process, however, may not reliably smooth and remove all possible internal voids or crevices. Learn more about chemical vapor smoothing.

It should be noted that with some materials and processes, it is simply not possible to get a food-safe surface finish even with the above-mentioned processes. Food-safe product design starts with the design, material, and manufacturing process; once these are properly chosen, mechanical finishing can help food-safe products reach safety standards.

Coatings

When mechanical finishing is not achievable or cost-effective, it is possible to coat non-qualified parts with a food-safe coating, thus allowing for food-safe 3D printing. These coatings can include anything from food-grade epoxy to polyurethane. They effectively smooth out the surface by filling in all the gaps and voids as well as creating an impervious food-safe seal between the part and the food. It's important that these coatings are free of typical coating defects (problems like blistering, delamination, and pitting, to name a few). These coatings should also be compatible with any cleaning products that are to be used to periodically clean the part in service.

How to Design Food Safe 3D Printed Parts

Food-safe 3D printing relies on many factors. Together, the materials, design, manufacturing method, and application will help a certifying body determine whether a product adheres to all safety standards. While Xometry cannot guarantee a product will be food-safe, our team of application engineers can provide expert guidance on which materials, design principles, and manufacturing techniques will put you on the best possible path to achieve the necessary level of food safety. Xometry offers eight different additive manufacturing technologies through its on-demand 3D printing service. To learn more about the options for food-safe 3D printing manufacturing, contact a Xometry representative today.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.