There are hundreds of metal 3D printers on the market, and deciding which is best for a specific application can be difficult. To aid in this process the 10 best metal 3D printers have been summarized to assist buyers.

The top three of those ten printers are listed below, along with their specific strong points:

- SPEE3D WarpSPEE3D: Highest speed metal 3D printer.

- Pollen AM PAM series MC: Largest number of materials printed.

- Desktop Metal Production SystemTM: Highest volume production.

This article will discuss the 10 best metal 3D printers on the market, how they work, their key features, and their cost. In addition, some general guidelines about how to select the best 3D metal printer will also be presented.

1. HP Metal Jet®

The HP Metal Jet® is a binder jetting style printer. This type of printer works by laying down a thin layer of metal powder from a build plate adjacent to a material drum. Then, an inkjet head sprays a binding agent on the powder in the shape of the part cross-section. Next, an energy source is passed over the powder to cure the binding agent. This process results in a green part that is finished in a standard sintering oven that both removes the binder and densifies the final part.Binder jetting results in printed parts with more isotropic properties than can be made using laser-based printers. The HP Metal Jet® costs around $400 000.

2. Velo3D® Sapphire

The Velo3D® Sapphire is a powder bed fusion (PBF) style 3D metal printer. It works by laying down a thin layer of metal powder, on which the shape of the current part cross section is traced by 2 x 1 kW lasers. The lasers melt the powder into a fully dense part. This printer has a 315 mm OD (outer diameter) x 1000 mm height build volume and can print advanced nickel alloys like Inconel®. The price of this printer is only available on request from Velo3D®.

3. SPEE3D WarpSPEE3D

The WarpSpEE3D® makes use of a unique supersonic 3D deposition technology that ejects metal powder from a nozzle at supersonic speeds. The high kinetic energy with which the powder hits the build plate causes it to fuse together. This machine has a 6-axis robot arm that orients the build plate and part to allow the print nozzle to deposit material where required. This printing technology is extremely quick. It can deposit material at a rate of 100 grams per minute, making it the fastest metal printer on this list. The machine requires a compressed air supply at 30 bar, with a flow rate capability of 1m3 /min. The price of this printer is only available on request from the SPEE3D.

4. Rapidia Metal 3D Printer

The Rapidia® metal 3D printer makes use of a unique water-binding process to print parts. TheRapidia® works similarly to an FDM (Fused Deposition Modeling) printer, depositing successive layers of a paste consisting of a metal powder plus a binder onto the build platform. Once the part has been completely printed, but before it is sintered, it can be bonded to another part using only water. The part is then sintered in a Rapidia® sintering furnace. Removable supports can also be printed, using a second print nozzle. This printer is simple and accessible due to a large online community for FDM style printers but these benefits come at the cost of a rougher surface finish quality that may require additional post-processing. The Rapidia® costs around $185,000.

5. XJet Carmel 700M

The XJet® Carmel 700M is a style of material jetting printer that deposits a liquid consisting of metal or ceramic nanoparticles suspended in a proprietary fluid carrier, using multiple inkjet-like nozzles. As soon as the layer has been deposited, the binder liquid evaporates due to the elevated temperature in the printer. Every droplet of material deposited by this process is used in the final part, resulting in no material waste. As is the case with standard plastic material jetting printers, high levels of detail are possible with the XJet® Carmel 700M. When the part is done printing it must be sintered to achieve its full, final density. Currently, the only metal this printer can print is stainless steel. The Carmel 700 M costs around $599,000.

6. Pollen AM PAM Series MC

The PAM Series MC is an FDM-style 3D printer that combines injection molding with 3D metal printing. This printer makes use of standard MIM (Metal Injection Molding) pellets as its raw material. This means that it does not make use of proprietary feedstock materials, and thus has one of the widest selections of materials available. Up to four materials can be printed simultaneously via independent printing nozzles. This printer is not just limited to metals, but can also print thermoplastics and ceramics such as alumina. The Pollen AM PAM Series MC costs around $140,000.

7. Digital Metal DMP2500

The Digital Metal® DM P2500 is a binder jetting-style printer. These types of printers work by laying down a thin layer of powder. An inkjet head then sprays a binding agent on the powder in the shape of the part cross-section. An energy source is passed over the powder to cure the binding agent. This results in a green part that must then be sintered in a sintering oven, there is no need to first de-bind the part. The DM P2500 can produce excellent precision and surface quality, meaning that parts often do not require post-machining. The DM P2500 is also easily incorporated into a fully automated process including the removal of the finished parts from the oven, automatic powder removal, and automatic transfer into a sintering furnace. The price of this printer is only available on request from Digital Metal®.

8. Trumpf TruPrint 1000

The TruPrint® 1000 is a powder bed fusion (PBF) metal printer that works by laying down a thin layer of metal powder. Next, either one or multiple lasers will trace out the current part cross-section, melting the powder into a fully dense part. The TruPrint® 1000 can automatically swap out multiple build plates to maximize productivity without stopping the machine. TruPrint® 1000 can be customized for different industries such as: dental plates, jewelry, laboratory equipment, or industrial fabrication of small series custom equipment. The price of this printer is only available on request from the Trumpf®.

9. DesktopMetal Production

Desktop Metal Production SystemTM is a binder jetting printer. The Desktop Metal version of this technology makes use of a unique method called single-pass jetting (SPJ). This 3D printer works by first depositing a layer of powder onto the build plate. The powder is precisely metered from the print head, in contrast to another binder jetting technology like MJF (Multi-Jet Fusion) that spreads a thin layer from a powder container next to the build plate. Immediately after depositing the powder, a compaction roller compresses the powder to a constant layer height. Next, a binder is applied in the shape of the part cross-section. This process is repeated until the part (called a green part) is completely printed. This green part then undergoes a cross-linking phase that slightly strengthens the part prior to powder removal. It is then referred to as a “brown part.” The brown parts are sintered in a furnace that evaporates the binder and fuses the powder into a fully dense, final part. The price of this printer is only available on request from Desktop Metal.

10. DesktopMetal Studio 2

This printer makes use of FDM technology called “bound metal deposition,” which works by extruding a metal powder mixed with a thermoplastic binder. The part is printed one layer at a time while a second nozzle deposits support material. When the part is complete, it can be placed into a furnace for debinding and sintering. The bound metal deposition process eliminates the process step of chemical debinding prior to sintering, and therefore reduces the manufacturing time. The Desktop Metal Studio SystemTM 2 costs around $120,000.

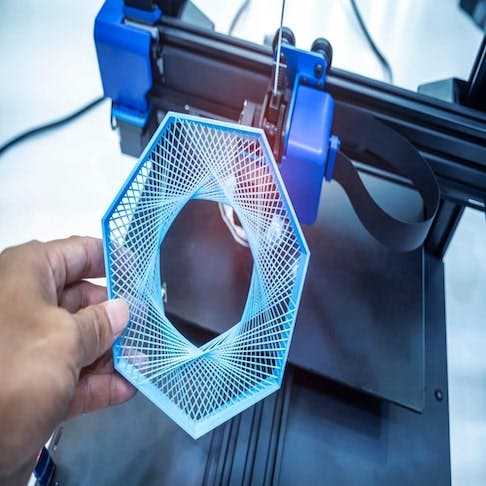

What Is a 3D Printer?

A 3D printer produces parts by building up the material into the desired part, as opposed to traditional subtractive technologies, in which the excess is cut away from a block of raw material to reveal the final part. 3D printers are able to produce parts printed in thermoplastics, photopolymers, ceramics, and metals.

For more information, see our guide on 3D Printing.

How To Choose the Best Metal 3D Printers

In choosing the best metal 3D printers, there are several factors to consider, including:

- Right Technology: Despite its capabilities, metal printing is a niche technology when compared to more established metal processing technologies like CNC machining or metal injection molding. For that reason, it is important to first confirm that a metal 3D printer is, in fact, the best solution for a given application. Some parts will still be cheaper and faster to produce using traditional techniques.

- Material to be Printed: Most 3D metal printers can only print a limited range of materials. This fact will play a major role in choosing a 3D printer.

- Cost: There must be a clear business case for purchasing a machine. An advanced high-production machine may not be necessary when the likely production volume and profit are weighed against the cost of 3D printing.

- Technology of the Printer: Most metal printing technologies can produce parts that have properties close enough to their nominal bulk properties so as to make them well suited to their end-use applications.

How Do Experts Determine the Best Metal 3D Printer?

Experts determine the best metal 3D printer for an application based on the underlying business case. If a low-cost printer is able to achieve the required part metrics, then it is a better choice than an advanced, high-cost machine. Ultimately, the tool is selected based on the requirements of the end part, such as: mechanical strength, unit cost, raw materials, and speed of production. The machine that best meets the requirements at the lowest cost is the best machine for that situation.

What Makes a Metal 3D Printer the Best?

The main factor that defines a metal 3D printer as “the best” is its ability to meet the required part specifications at the lowest cost. The specific printer technology is not as important as selecting a system that can achieve all of the required results. For example, an FDM style printer is better suited to hobbyist applications due to lower costs. However, for end-use components for high-performance parts, a laser-based printer may be better suited.

What is the Best Metal 3D Printer for Beginners?

The best beginner-friendly metal 3D printers are listed below:

- Desktop Metal Studio System™ 2: Desktop Metal Studio System™ 2 is the best printer for beginners because it is low cost, can produce fully functional metal parts, and has a simple two-part process.

- Pollen Pam Series MC: This printer is able to print almost any material. It can make use of standard injection molding materials, making it both a low-cost and very accessible printer.

- Rapidia Metal 3D Printer: This printer makes use of familiar technology, i,e, FDM (Fused Deposition Modeling). The parts can be simply fused with water prior to sintering, allowing for the manufacturing of very complex parts.

Is a Metal 3D Printer Useful?

Yes, metal 3D printers can be used for a wide range of applications, especially in the aerospace, medical, and automotive industries.

Summary

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Copyright and Trademark Notices

- HP METAL JET is a registered trademark of HP Hewlett Packard Group LLC.

- Velo3D Sapphire is a registered trademark of Velo3D, Inc.

- Inconel® is a registered trademark of Special Metals Corporation

- DESKTOP METAL, Production SystemTM, Studio SystemTM is a trademark of Desktop Metal, Inc.

- WarpSpEE3D® s a trademark of Effusiontech Pty Ltd PROPRIETARY LIMITED COMPANY

- Rapidia® is a trademark of Tech Inc BC company

- XJet® is a trademark of Xjet, Inc. CORPORATION

- DIGITAL METAL® is a trademark of AB CORPORATION

- Truprint® & trumpf® is a trademark of TRUMPF SE + Co. KG GMBH & CO. KG FED REP

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.