Binder jetting and material jetting are two related 3D printing technologies that, on the surface, have similarities. On closer examination, the differences are much greater. Binder jetting is a material-adaptable, powder-bed process. Model slices are bonded and keyed to the slice below by jetting a wide range of adhesive compounds by bubble-jet or inkjet methods, to print/bond a picture of the slice.

Material jetting also uses bubble-jet technology, but prints model slices directly onto a build table. It generally uses modified acrylic resins or epoxies. Binder jetting provides cost-effective, rapid production of relatively low-resolution parts in an extensive range of materials, while material jetting offers higher resolution suitable for detailed plastic prototypes and models. The selection of applicable technology depends on the project's specific requirements, including resolution, materials, and production volume.

This article will discuss the differences between binder jetting vs. material jetting in terms of their processes, advantages and disadvantages, material selection, types, and more.

What Is Binder Jetting?

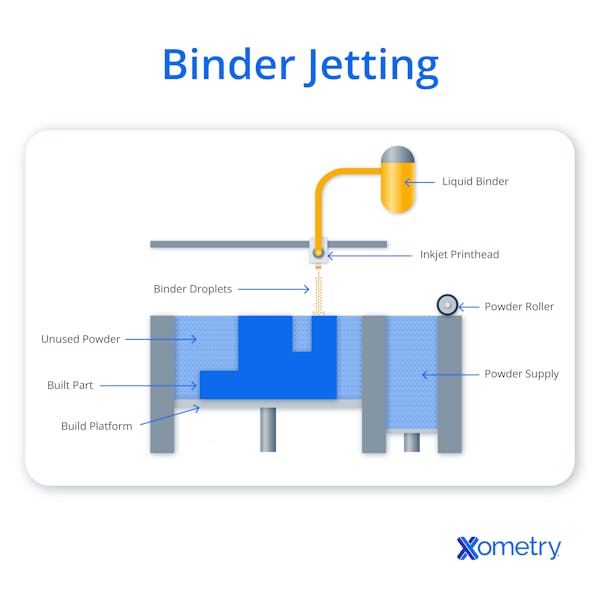

Binder jetting is an additive manufacturing process in which a powdered material, typically metal, sand, plaster, or ceramic, is deposited layer by layer. A liquid binding agent, usually a polymer, is selectively deposited onto the powder bed to adhere particles together. This process creates each slice of the 3D model by solidifying the binder upon contact or through a post-curing step.

The binder is applied using inkjet-style heads, such as piezoelectric or thermal (bubble jet) nozzles. Once deposited, the binder causes the particles in that layer to bond to each other and the previously printed layer. The unbound powder remains loose, serving as a natural support structure during the build. At the edges of the printed area, capillary action causes the binder to bleed slightly into the surrounding powder, which can reduce resolution and edge definition—especially in fine powder applications. This bleed zone is one of the primary limitations for achieving high-resolution features.

Some binder jetting systems incorporate an additional print stage to deposit full-color pigments, enabling the creation of detailed, multi-colored prototypes. These colors are embedded within the part and can withstand post-processing steps such as infiltration, sanding, or sealing.

To learn more, see our guide on Binder Jetting.

What Are the Advantages and Disadvantages of Binder Jetting 3D Printing?

Binder jetting has advantages and disadvantages, often making its selection for a project a clear-cut decision. The benefits of the approach are:

- Faster build times than many other 3D printing processes, especially for large or batch-printed parts.

- Cost-effective for bulk production, as the raw materials (powders and binders) are generally low-cost, and the process requires no support structures beyond the surrounding powder bed.

- Low material waste and simple post-processing, with unused powder easily reclaimed and reused.

- Wide material compatibility, including metals (e.g., stainless steel, bronze, aluminum), ceramics, sand, and plaster.

- Capable of producing complex geometries and internal features that would be difficult or impossible to manufacture using traditional methods.

- Large build volumes are achievable, thanks to the relatively simple hardware and scalable powder bed setup.

The widely reported disadvantages of binder jetting are:

- Parts produced by binder jetting typically have a grainy or porous surface texture, as they are formed from bonded powder. While earlier systems used powders with particle sizes around 100 µm, modern systems have reduced this to approximately 10 µm. Nonetheless, surface smoothness remains inferior to other printing methods like SLA or material jetting.

- Green parts are mechanically weak and unsuitable for load-bearing applications. Sintering can improve strength, but the process introduces shrinkage and distortion, affecting dimensional accuracy. Even with sintering, dimensional accuracy can be challenging to maintain due to shrinkage and thermal distortion.

- Binder jetting parts often exhibit significant internal porosity. Additional steps such as metal infiltration, hot isostatic pressing (HIP), or sintering are required to achieve adequate strength or density, which add cost and complexity.

- The resolution is moderate; binder bleeding at print edges reduces detail compared to higher-resolution technologies like SLA or material jetting.

- Material properties are generally inferior to those achieved with methods like SLS, DMLS, or FDM with reinforced filaments.

- Safety concerns exist when working with fine powders. Metal and ceramic dust pose inhalation and contamination risks, requiring proper ventilation and personal protective equipment (PPE).

What Are Examples of Binder Jetting 3D Printing?

One of the most common applications for binder jet printing is making photographic props, such as product packaging and figurines, that are required for zero-stress applications. Increasingly, binder jetting is reported as a practical means for rapidly producing metal components of relatively low precision and coarse surface finish. While such parts are restricted in their application, where the properties are appropriate, they can serve very well and at relatively fast production and low cost.

What Is Material Jetting?

Material jetting is a 3D printing technology that uses inkjet or bubble-jet printing methods to deliver liquid photopolymer or wax build and support materials directly onto a build platform. The printed material is either partially or fully cured in the print process before the table lowers and the next slice of the model is applied.

The print process generally applies two (or more) related materials in the layer construction. Build materials are typically heat-cured or UV-light-cured polymers that can be rigid, semi-flexible, or pseudo-elastomers. Some variants of the process use wax as the build material, allowing direct production of investment casting masters of the highest quality without the need for skilled craftsmanship. Support material is co-printed by additional printer heads. Such support material will be either chemically soluble or a water-soluble version of the build material that couples fully to the model but can be later removed. Advanced systems may allow mixing or alternating different build materials during printing. This enables property gradation, where the mechanical characteristics of a part vary by region (e.g., from soft to rigid) and material switching, to change functional behavior within the same part geometry.

To learn more, see our guide on Material Jetting.

What Are the Advantages and Disadvantages of Material Jetting 3D Printing?

The advantages of material jetting are:

- It offers exceptional print resolution, the highest in commercially available equipment. It is ideal for printing intricate models with fine detail and thin sections.

- Some machines in this class can simultaneously print with two materials in variable proportions from 0–100%. This allows for the creation of variable and custom material properties and, to a very limited degree, some color variation options.

- It offers high-dimensional accuracy and repeatability. When machine calibration is thorough and correctly performed, printed parts closely match their digital designs.

- The machine type for this process is relatively fast compared with other good-resolution technologies like stereolithography (SLA).

- The photopolymer materials available include: rigid (various colors), flexible (rubber-like from 30 to 90 Shore A), transparent (lens/window quality), and biocompatible options. The material family is continuously expanding, and material properties are slowly improving to approach those of molded plastics.

- Support materials, co-printed with the build, are easily removable and maintain the integrity of complex overhangs and geometries, without excessive cost or cleanup difficulties.

- Unlike SLA, material jetting doesn't require post-curing in UV chambers, simplifying the post-processing steps. The resins are cured immediately after printing, as powerful UV lamps pass over them in the same process.

Some disadvantages include:

- The photopolymer materials used are high to very high cost, and they are generally single-source.

- It is limited to proprietary photopolymer resins and lacks the wide range of options available in some other technologies.

- Often has smaller build volumes compared to some 3D printing technologies.

- Removing certain complex supports can be a delicate and skilled manual process. Additional post-processing steps are commonly needed to achieve a cosmetic finish.

- Equipment maintenance and basic, everyday OPEX are skilled tasks and require high-cost, single-source components. This adds considerably to per-print costs, and cost savings in this regard can have disastrous consequences.

What Are Examples of Material Jetting 3D Printing?

Some examples of material jetting 3D-printed parts are:

- Precise models for dental crowns, bridges, and dentures, where accuracy and surface quality are critical.

- Detailed wax patterns for investment casting, especially for jewelry and small metal components that require fine detail and smooth surfaces.

- Engineering prototypes of aerospace components are used for fit, form, and aerodynamic testing before final production.

- Consumer electronics prototypes, including custom device enclosures, miniature component housings, and design evaluation units.

- Microfluidic devices with intricate internal channels are used in diagnostics, life sciences, and research. This includes complex parts like microdispense nozzles and Tesla-type microvalves, which are costly or impractical to produce using traditional methods.

Choosing between binder jetting and material jetting depends on matching each process to the intended application. Binder jetting excels when cost-effective production, large build volumes, or metal and sand printing are needed, while material jetting stands out for its unmatched resolution, surface quality, and ability to combine materials in a single build. Both technologies fill distinct roles within additive manufacturing, and understanding their differences in process, materials, and performance helps ensure the right choice for design goals, production volume, and functional requirements.Mahder Tewolde, Ph.D., PENote from the Editor

Which Is Better, Binder Jetting 3D Printing or Material Jetting 3D Printing?

The choice between binder jetting and material jetting depends on the application's specific requirements, such as material compatibility, resolution, cost, and post-processing demands. Material jetting is generally preferred for high-resolution printing tasks where accuracy, surface finish, and intricate detail are critical. It is ideal for applications that involve rigid or rubber-like polymers, transparent parts, or biocompatible components. It is also the dominant method for directly printing wax parts used in high-precision investment casting. While binder jetting has made strides in flexible materials, those parts typically lack mechanical strength and precision, making them unsuitable for functional or structural use.

Binder jetting, on the other hand, is currently the only practical method for 3D printing metal parts without melting processes. It is also the go-to technology for producing sand molds and cores for casting applications, and the best option for full-color prints in visual or presentation models. Although material jetting cannot print metal, it surpasses binder jetting in polymer part accuracy, material flexibility, and fine feature reproduction.

Difference in Terms of Process

Binder jetting is a powder-based technology. It deposits a liquid binding agent onto layers of powder (e.g., metal, sand, or ceramic). After printing, the loose, unbound powder is removed, and the printed part may undergo post-processing steps such as sintering or infiltration. Material jetting, in contrast, uses inkjet-style printheads to deposit tiny droplets of photopolymer directly onto the build platform. These droplets are UV-cured during printing, and support material is simultaneously deposited using separate nozzles. Once printing is complete, supports are removed via water or chemical washes.

Difference in Terms of Types

There are several classifications of binder jetting 3D printing: single-material binder jetting, multi-material binder jetting, color binder jetting, sand binder jetting, metal or ceramic binder jetting, polymer binder jetting, and hybrid binder jetting.

In single-material binder jetting, a single powder is used, and the binding agent is deposited to create the object layers and bind them to the layer below. Multi-material binder jetting employs multiple powder materials, generally in alternating layers of metals, ceramics, and polymers. The selection of binding agents to suit each powder material enables printing multi-material, composite, or property-graduated parts.

Color binder jetting includes full-color 3D printing. It generally combines gypsum build materials and printable binding agents with full-color inkjet printing on each layer, for full-color prints. Sand binder jetting uses fine sand as the build material to create sand molds and cores for metal casting. Metal or ceramic binder jetting uses metal or ceramic powder as the build material. After printing, the green part is sintered to shrink/fuse the metal particles to full density and burn out the binding agent. Polymer binder jetting is specific to the layering of polymer powders, often using a solvent-binding agent that welds the particles.

In some cases, the binder jetting device can operate in more than one listed mode. It can also be integrated with other 3D printing technologies to allow regional selectivity in appropriate processes applied to a build. This is known as hybrid binder jetting.

There are also several classifications of material jetting technologies, differentiated by method and materials. Polymer material jetting is the most common and earliest form of material jetting, depositing polymer inks in liquid or gel form. These polymers are generally UV-cured in place for rapid and finished printing with limited post-processing. Multi-material jetting uses the simultaneous deposition of multiple materials (usually two), such as rigid and elastomer types, to build graduated properties, graduated colors, and sudden material changes in parts.

Full-color jetting is a specialized category that delivers full-color and high-resolution components for the production of figurines, architectural models, and artworks. Ceramic or metal material jetting deposits ceramic-based or metal materials in a polymer suspension, to create intricate ceramic parts that can be sintered to achieve the final ceramic density. Microfluidic material jetting is used to create microfluidic devices with precise channel geometries for applications in research, diagnostics, and fluid-logic devices. Wax material jetting is used in jewelry for pattern making in lost-wax casting. Wax patterns are directly printed as sacrificial masters for metal part production.

Difference in Terms of Materials Used

Material jetting builds directly into polymer models of rigid, elastomeric, and wax materials. Binder jetting, on the other hand, generally uses polymer bonding agents to adhere to various powder materials ranging from metals to ceramics and sand.

Difference in Terms of Applications

Material jetting is suited to functional and design evaluation prototypes that can be used to assess assemblies, test mechanism performance, and, when required, substitute for molded parts. Wax prototypes can be directly used to produce investment castings, printed with all sprue and channel parts pre-attached and integral in a single stage.

On the other hand, binder jetting provides visual test components of relatively low precision and poor mechanical properties. These are suited to visual evaluation of shape and aesthetics, and can directly produce examples of packaging and color-critical prototypes for photographic props, etc.

Difference in Terms of Machine Characteristics

Binder jetting machines handle powders, laid down in layers that are wiped and, in some cases, roller packed to height. These machines have a difficult material handling task in this aspect of the process, which makes them relatively complex and can create reliability issues if powders are abrasive and the machine hygiene is poor. Additionally, the jetting component of the machine that delivers the bonding agent is a relatively simple single printhead that requires little customization to the task and offers simplicity and reliability.

Material jetting uses a similar-in-principle jetting system to deliver the build polymers directly to the build platform. These heads are highly customized, creating significant setup and maintenance issues that result in ongoing high effort in OPEX. Binder jetting machines are reliable and low-maintenance. Material jetting machines are delicate precision instruments that require regular and skilled daily, weekly, and intrusive maintenance and setup.

Difference in Terms of CAD Software

Both material jetting and binder jetting technologies use standard 3D CAD file formats, typically exported as .STL files, which are then sliced using either proprietary or third-party slicing software to prepare the data for printing. For material jetting, the .STL resolution should be set to fine, and the layer height must match the machine’s capability to leverage its high precision fully. Careful attention to tessellation and surface detail is essential to maintain the fidelity of intricate features during printing.

For binder jetting, especially in full-color printing, there is a key difference: the .STL file format does not inherently support color data. In these cases, additional proprietary file extensions (such as .WRL, .3MF, or color-augmented formats) are used, or the color information is embedded separately and combined with the geometry during slicing. This step is necessary to assign accurate textures and color mapping to each print layer.

Difference in Terms of Cost

Binder jetting machines typically cost between $30k and $200k, increasing as superior capability and build volume are required. Material jetting machines, on the other hand, start at around $20k for a desktop-size machine with moderate resolution and limited build speed. Prices rise to $750k for the more advanced and precise machines capable of multi-material printing. These require highly skilled operational and maintenance labor, plus some limited ancillary equipment.

Difference in Terms of Quality

Quality is a term that is open to interpretation. Quality differentials between the technologies can be mapped according to function.

Material jetting offers higher-resolution builds than binder jetting. If precision and accuracy are quality references, the differential can be a factor of 3–5 in favor of material jetting. If metal or sand printing is required, material jetting cannot serve, and binder jetting is the clear quality choice. If full-color printing is needed for the prototype, material jetting cannot provide this, whereas some types of binder jetting equipment can. If functional parts and material qualities are necessary for non-metal parts, material jetting offers significantly higher quality than binder jetting.

Difference in Terms of Accuracy

Accuracy can be measured in various ways. Before selecting these criteria, it’s critical to consider the project's real needs.

Both processes offer good repeatability, so multiple-part consistency is suitable for the two types. Binder jetting delivers lower resolution than material jetting, so the fineness of models is considerably different. The imprecise nature of binder jetting delivers a less accurate representation of small features than can be achieved in material jetting.

Difference in Terms of Manufacturer

With lower operational and capital costs, as well as a considerably lower cost of setup and ongoing overheads, binder jetting is suited to in-house use. However, there is a strong tendency to centralize services in contract printing companies, as few companies have the volume of need that justifies the in-house setup investment.

Surprisingly, material jetting is commonly the in-house choice for larger companies with sufficient demand to justify the investment and operational costs. However, few companies can show ROI on this cost, so there is the same tendency towards centralized service providers who can support a wide range of capabilities and attract enough demand to justify ongoing investment.

Frequently Asked Questions About Binder Jetting and Material Jetting

Is a Material Jetting 3D Printer Fast?

No. The build-layer thickness or Z-axis resolution of binder jetting machines is generally greater than that of material jetting equipment, making overall printing times shorter for binder jetting. In addition, the post-print cleanup of binder jetting is minimal, increasing the overall process speed differential.

Can a Material Jetting 3D Printer Print Metals?

No, material jetting offers no direct metal printing process.

Does Binder Jetting 3D Printer Require Supports?

Binder jetting is built within a stable and complete machine volume powder mass, so no separate support structures are required for this printing type, reducing the post-work required for print jobs.

Summary

This article presented binder jetting vs. material jetting, explained each of them, and discussed their key differences. To learn more about binder jetting and material jetting, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.