Carbon fiber, a.k.a. graphite fiber or carbon graphite, has become a firm favorite in several sectors, and for good reason. But we won’t give it all away in the intro: read on to find out what this material is, its different types, and what it’s used for.

What is Carbon Fiber?

Carbon fiber is a fabric mat made of woven fibers and is classed as both a composite and fiber-reinforced plastic. It’s 90% polyacrylonitrile (the carbon precursor) and 10% other precursors, like pitch or cellulose. This material is made by carbonization, oxidation, or graphitization. It’s first cut into the required shape, impregnated with resin, then processed in one of the aforementioned methods. When cured, the result is a lightweight and incredibly strong material with an impressive strength-to-weight ratio.

This type of fiber’s high heat tolerance was what inspired Sir Joseph Wilson Swan to use it for an incandescent lightbulb in 1860. Back then, carbon fiber filaments weren’t as strong as they are now, so when tungsten came onto the scene, it pretty much took over in the lightbulb-making department. More than 50 years went by without carbon fiber being really used for anything, but a stronger version was brought out in the 1960s, and Rolls-Royce snapped it up for its jet engines—despite the brittleness thing.

The carbon fiber that’s used in manufacturing today has a tensile strength of around 4,000 MPa and a high modulus of 400 GPa, making it useful for a whole host of things (not just bulbs). It’s resistant to creep, fatigue, chemicals, and corrosion, as well as nonflammable and nontoxic. With the right treatment, it can be electrically conductive.

This material is infamously expensive. It’s both lighter and stronger than steel, but its high cost puts manufacturers off from using it unless absolutely necessary (kind of like that pricey fragrance you’re saving for special occasions). But now the price of carbon fiber has gone down, and its usage up! Carbon fiber’s days of waiting for high-profile tasks are over; it’s now made into tools and fixings, springs and wires, and can even be used to reinforce tires.

What Is the Other Term for Carbon Fiber?

Carbon fiber can also be referred to as graphite fiber or carbon graphite. It may be referred to under the umbrella terms composite or fiber-reinforced plastic. The term composite is used to describe a material that has a matrix and reinforcement. In the case of carbon fiber, the fiber is the reinforcement and the resin is the matrix. Fiber-reinforced plastic is used to describe glass fiber and aramid composites as well as carbon fiber.

When Was Carbon Fiber Invented?

Carbon fibers were first created in 1860 by Sir Joseph Wilson Swan for use in an incandescent lightbulb as these fibers had a very high heat tolerance. However, carbon fiber filaments at the time were not very strong. So when tungsten started being used in lightbulbs, carbon fiber had no use for over 50 years. Then, in the 1960s, stronger carbon fibers could be produced for use in jet engines by Rolls-Royce. However, due to the brittle properties of carbon fiber, its use was limited for a long time. Since then, carbon fiber production has become much more effective. Carbon fiber today has a tensile strength in the range of 4,000 MPa and a modulus of 400 GPa which has opened up many more applications for its use.

What Is Carbon Fiber Made Of?

The oxidization, carbonization, and graphitization of the carbon precursor polyacrylonitrile make up 90% of carbon fiber material. The other 10% of precursors used are either from pitch or cellulose.

What Are the Properties of Carbon Fiber?

The non-mechanical properties of carbon fiber are:

- Electrically conductive

- Corrosion resistant

- Nonflammable

- Nontoxic

What Are the Mechanical Properties of Carbon Fiber?

The mechanical properties of carbon fiber include:

- Lightweight

- High strength

- Creep resistant

- Fatigue resistant

- High modulus

- Brittleness

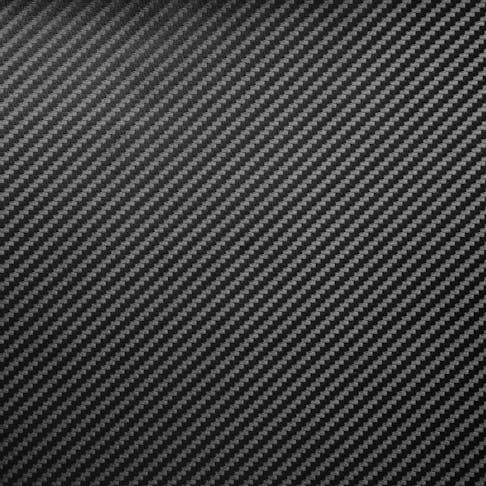

Twill weave

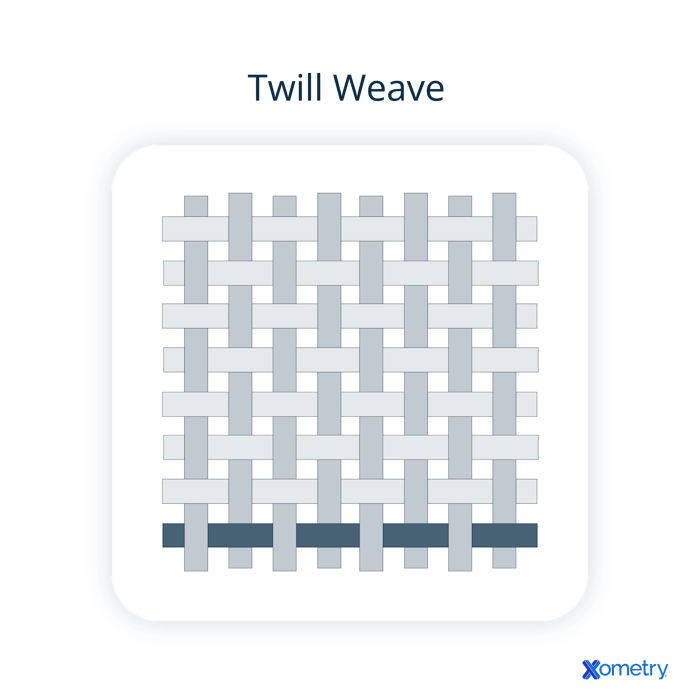

Satin: Smooth and glossy, ideal for draping

Satin weave

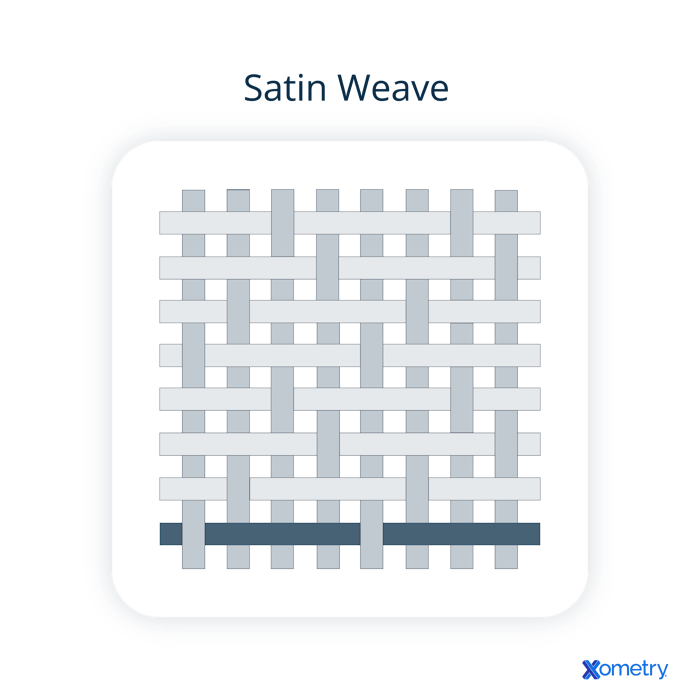

Basket: A flat, two-over/two-under pattern with more thickness and stiffness, but less flexibility.

Basket weave

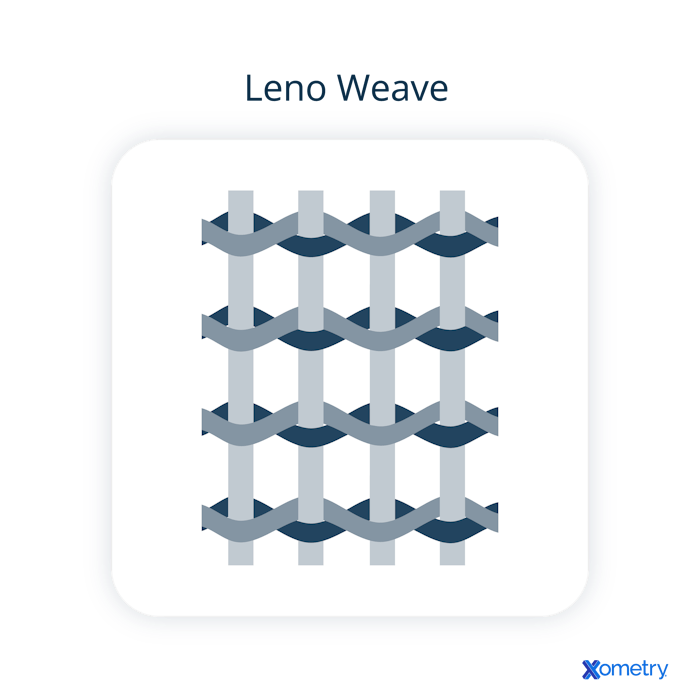

Leno: A criss-cross pattern that keeps fibers securely in place to prevent unraveling.

Leno weave

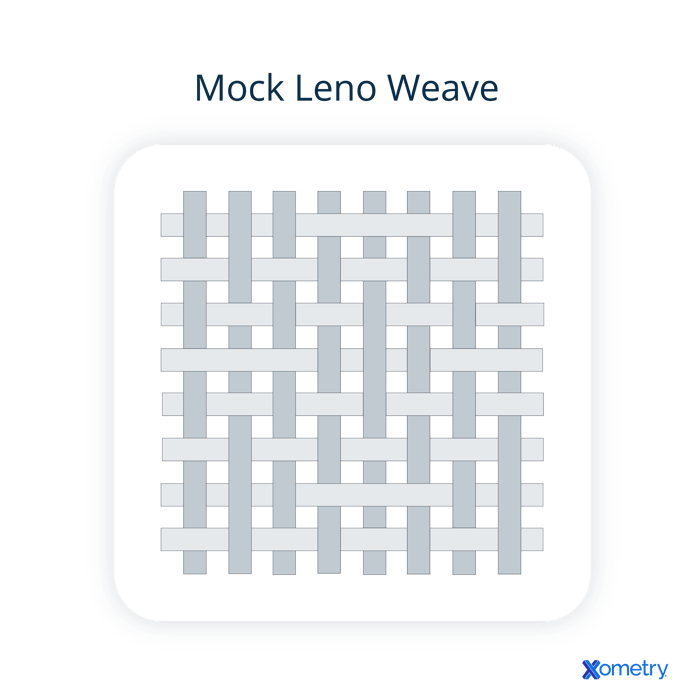

Mock leno: Looks like leno but is a little more flexible and less stable.

Mock leno weave

The number of times a fiber goes over and under other fibers is known as the crimp, and the higher the crimp, generally, the higher its stability. But high-crimp carbon fiber means the material won’t be very flexible (known as its drapability) to form intricate shapes or geometry.

How Strong Is Carbon Fiber?

Carbon fiber is categorized into: standard, intermediate, high, and ultra-high modulus quality and ranges from 3.55 GPa of tensile strength.

Is Carbon Fiber Heavy?

No, carbon fiber is not heavy. Carbon fiber is very lightweight which is one of its two most desired properties, the other being its strength. The weight of carbon fiber will depend on the number of fibers per cm2 and the resin used to bind it. As an example, a plain twill weave of carbon fiber without resin will weigh 210 g/m2, with a thickness of only 0.28 mm. For comparison, steel has a weight of 4 kg/m2 for a thickness of 0.5 mm.

What Are the Chemical Properties of Carbon Fiber?

The chemical properties of carbon fiber are:

- Chemical-resistant

- Nontoxic

- Nonflammable

What Are the Different Advanced Applications of Carbon Fiber?

Because of its high price tag, carbon fiber is currently only used in high-performance applications, a few of which we list below.

1. Aerospace Industry

Its low weight makes carbon fiber suitable for aircraft fuselage, empennage, nose cones, and rotor blades. When these parts are made from this material, aircraft weight can be reduced by up to 20%, something that saves millions of dollars in fuel.

2. Sporting Goods

It’s used to make lighter, stronger, and faster-moving tennis rackets, skis, snowboards, bikes, and golf clubs. Just be prepared to pay a lot more for carbon fiber sports equipment.

3. Medical Devices

X-ray devices and implants are made from carbon fiber mainly because it is radiolucent (X-rays can pass through it easily). It’s also wear-resistant and has a similar stiffness to human bone. Unlike the metal used in some implants, carbon fiber is brittle and could shatter.

4. Energy Storage System

Plans for carbon fiber battery storage systems are in the works, which could greatly reduce the weight of electric cars.

5. Civil Engineering

Carbon fiber is becoming increasingly popular in bridges and concrete structures where strength is more important than weight. Because it can be up to ten times stronger than steel, it’s preferred, but as we’ve established, it’s much more expensive to use.

6. Marine Technology

As carbon fiber’s price is on the decline, it’s starting to replace the use of fiberglass in yachts and small boats.

7. Military and Defense Technology

Drones, helicopters, jets, and transport aircraft can all be made using this material. The design of helmets has become much more complex over the years—something that also makes them heavier. Carbon fiber is here to save the day (but there’s still the issue of difficulty detecting damage).

One downside, though, is something called Barely Visible Impact Damage. Basically, it’s hard to spot damage on this material with the naked eye, so checking for faults needs extensive training and testing. This factor affects most of the above industries, but especially aerospace, energy, marine, and military.

How Can Carbon Fiber Be Utilized Together With 3D Printing?

Carbon fiber is compatible with 3D printing. It can either be used as a continuous fiber layer or printed as short strands in the filament of an FDM (Fused Deposition Modeling) printer. The printer will need two printheads if you are to print with a continuous fiber: one for the plastic filament and one for the carbon fiber. If you choose to embed chopped strands within the filament, you can improve the strength and stiffness of printed parts without going bankrupt. Using this material in 3D printing means you can make parts that can be used for structural purposes because they’re way stronger than the typical PLA and ABS used in 3D printing. With carbon fiber, parts can be compared in strength to materials like aluminum.

The aerospace industry is using 3D-printed carbon fiber parts to some extent. Because of safety regulations, any new technology or materials need to undergo extensive testing and qualification before being used in aerospace, but for now, it’s not uncommon to find parts for brackets and specialized tooling made from 3D-printed carbon fiber. Companies don’t have to deal with huge lead times, either.

Frequently Asked Questions About Carbon Fiber

How Does 3D Printing in Aerospace Industry Used Carbon Fiber To Create Different Part?

Currently, 3D printing with carbon fiber in the aerospace industry is limited. Using new materials and processes requires an extensive amount of qualification before use in aerospace. However, many aerospace companies are using 3D-printed carbon fiber parts for brackets and specialized tooling. 3D printing is being used to create limited production parts which would otherwise have long lead times. Many repairs and maintenance tasks require specialized tooling which has high costs and long lead times. With 3D-printed carbon fiber, lead times and costs are now being slashed.

To learn more, see our full guide on 3D Printing in Aerospace.

What Is the Advantage of Carbon Fiber Compare to Other 3D-Printed Materials?

The advantage of carbon fiber printed parts is the increased strength when compared to other 3D-printed materials. Most 3D-printed parts are made out of PLA or ABS which are relatively weak, meaning the parts cannot be used for structural purposes. However, with 3D-printed carbon fiber materials, the strength is comparable to that of aluminum. This opens many applications for the use of 3D-printed parts.

Is Carbon Fiber Stronger Than Steel?

Yes, carbon fiber is stronger than steel when comparing their respective strength-to-weight ratios. While both steel and carbon fiber have an elastic modulus of 200 GPa, steel is five times heavier than carbon fiber. This high strength-to-weight ratio is why carbon fiber may be preferential in many applications.

Is Carbon Fiber Stronger Than Aluminum?

Yes, carbon fiber is much stronger than aluminum. Aluminum can reach up to 570 MPa whereas ultra-high modulus carbon fiber can reach a tensile strength in excess of 5.5 GPa.

What Is the Difference Between Carbon Fiber and Carbon Fiber 3D Filament?

Both traditional carbon fiber and 3D-printed carbon fiber add strength and are lightweight, but the method of application is very different. Traditionally, carbon fiber is a weaved mat of fibers that have a resin applied and then cured. Traditional carbon fiber is usually made into larger panels and tubular sections but can be made into brackets. 3D-printed carbon fiber is either chopped into micro strands and added to a filament from which it is printed into a part usually with complex geometry or is printed as a singular continuous strand in discrete layers of a 3D-printed part.

How Xometry Can Help

For more info on carbon fiber, feel free to reach out to one of our reps, or request a free no-obligation quote for any one of our manufacturing services, like CNC machining, 3D printing, and carbon fiber laser cutting, to name just a few.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.