Materials deform all the time, but knowing exactly why and how it happens is essential for an engineer or manufacturer—and helps them prevent it to begin with. One example of this is creep deformation. As its name sounds, it really can sneak up on you as it happens over time rather than suddenly and usually impacts metals like steel and polymers. The ability to read and understand a creep graph, and what sets this kind of deformation off in the first place, will help you stop materials from going through this annoying change.

What is Creep Deformation?

When a material is put under a lot of stress for a long time, creep, a mechanical deformation type, can occur. Although it happens at a slower rate than other types, creep deformation can still make a material fail. Many things can impact how fast it happens, too, like material properties, environment, temperature, and the particular stress level and type it’s put under.

We could use the very basic example of a reusable metal water bottle that lays at the bottom of a worker’s backpack each day, under all their tools. At first, the bottle may look completely fine and unchanged, but over time, some of its parts (maybe the metal around the cap or the bottom) could start to bend slightly. This won’t happen all at once—the water bottle won’t just suddenly concave—but factors like the hot liquid and the constant pressure from the heavy tools lying on top of it can soften the metal just enough to let it stretch. It might be tough, and generally resistant to wear and heat, but the prolonged stress it’s put under can cause the water bottle’s material to creep.

There are a few telltale signs or environmental factors you can check that’ll help you recognize when creep deformation is happening. When it comes to steel, this will only experience serious creep levels if under heavy loads and stress in temperatures that reach at least 40% of its melting point and stay that way for an extended period.

For something like concrete, it’ll depend heavily on the amount of aggregate in the mixture and how many temperature and stress fluctuations are taking place. This can lead to permanent deformation in structures and surfaces made of concrete. Other materials that you’ll find undergo creep deformation are polymers like nylon, ABS, and polyethylene. To avoid it completely, you can find superalloys out there that are highly creep-resistant. Knowing why and when creep pops up can help engineers prevent materials from failing, keeping structures safe and in good working order.

It’s also a common problem you’ll come across in 3D printing. This is particularly true for the likes of fused deposition modeling methods. When the filaments are put under nonstop stress, molecular chains will change and creep happens. Heat creep is also a real threat that involves heat traveling up your printed object (without you wanting it to) and leading to deformation.

The Creep Deformation Graph

There is a graph that helps visualize creep deformation and is broken down into the three stages of creep, which we’ll delve into. You can get an idea of how this graph looks and the information it tells you in the image below.

You’ll notice the first section shows a material when it first starts undergoing long-lasting strain and stress. The second portion of the graph is when creep deformation really starts happening at a constant rate. The third area shows the creep strain rate of the material as it works its way to the point of rupturing. Hotter temperatures normally lead to higher strain rates and speed up the timeline of material finally rupturing.

The Equation

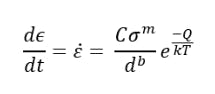

You can calculate creep with the help of an equation. It looks like this:

Creep equation.

The letters and symbols stand for the following:

- C - Constant, and this will change depending on the creep mechanism and the material

- σ - The stress that’s being applied to the material

- m, b - Exponents that also depend on the creep mechanism

- d - The average grain size of the material

- Q - Activation energy of the deformation

- k - Boltzmann’s constant

- T - Absolute temperature

Creep Stages

As the graph shows, there are three stages that happen during creep deformation, which we’ll take a closer look at.

1. Primary

Also known as transient creep, this happens right when a load is added to a material. It’s an elastic phase and the creep rate will actually reduce here as the material undergoes strain hardening.

2. Secondary

After primary, comes the next stage, which also goes by steady-state creep. This tends to be the longest phase of creep. Strain is still happening here, but the material also experiences a softening that allows deformation to take place. While the whole graph is important, the secondary creep rate is especially so as engineers use a parameter when they’re designing structures and objects.

3. Tertiary

This is the last stage that you’ll see on the graph. It gives you a good visual of the point when stress and temperature finally lead to rupturing and creep failure due to internal voids, micro-cracks, and grain boundary separation.

Deformation Types

There are a few ways or mechanisms in which creep deformation makes an appearance, and here are seven of them:

Nabarro-Herring

For this type of creep to take place, you need low stress and high temperatures. As the temperature gets hotter, the atoms that are in the crystal lattice of the material’s grains diffuse and vacancies in the structure appear. Materials with larger grains will see a slower creep rate, and smaller grains will see a quicker rate.

Polymers

It’ll be no surprise that this creep happens specifically to polymers that are put under stress and hot temperatures. But, this type can even happen at room temperature. The main mechanism found in the creep of polymers is the polymer’s chains sliding. You’re less likely to find it in crystalline polymers—it’s a more common deformation in amorphous types.

Dislocation

This happens when the atoms themselves discolate, either through glide or climb dislocations. Sometimes called power law creep, this deformation depends on atoms moving horizontally or vertically in a parallel or perpendicular manner, causing vacancies.

Coble

At cooler temperatures, something called coble creep can happen. This happens on the boundary of the material’s grain (rather than inside of it), which is why you don’t need searing hot temperatures for it to take place. These boundary grains will shift perpendicular to the stress, causing the creep.

Solute-Drag

This creep happens to alloyed materials, which have elements that are normally highly creep-resistant. Fractures will snake their way in when the atoms within the solute begin to deform when the temperature is extremely hot.

Harper-Dorn

This is another form of dislocation creep, but in this instance, the size of the grain doesn’t impact the strain rate. That said, there are a few factors that need to line up for this creep to happen. Firstly, grains have to be larger (at a minimum of 0.5 mm), the composition should be very elementally pure (no less than 99.95%), and there should be a little dislocation density present. After this, it doesn’t take much for it to show face. With temperatures that are 35% to 60% of the melting temp of the material and low-stress levels, this creep can occur.

Sintering Limit Stress

Sintering is a process that heats up material and fuses it together, but during the process, a version of creep can appear. When the pores between the particles stop shrinking and the material’s density increases, you hit the stress limit and see creep.

Preventing Creep

There are a few preventative measures you can put in place to keep creep at bay and factors to keep an eye on when you’re working with materials that are subject to this kind of deformation. The first is getting to grips with the stages of creep in various materials. It’s helpful to make a note of when materials you use reach their secondary phase so that you can choose one that can handle the conditions you need it to.

Choosing metals without directionally casted grains, superalloys, or materials that have been dispersion-strengthened will lower the chances of dislocation (the number of grains available in the material) and lead to creep. Since creep needs time to really set in, you do have some time to catch it before it’s too late. Going for materials with high melting points or keeping the temperature surrounding it as cool as possible (if and when possible) can also help prevent it.

How Xometry Can Help

We help process and manufacture all kinds of materials here at Xometry, including steel and polymers. If you’re interested in services under this umbrella—from 3D printing to laser cutting—you can get free quotes for plastic 3D printing, metal extrusion, steel CNC machining, selective laser sintering 3D printing, and stainless steel laser cutting on our website.

Copyright and Trademark Notices

- Inconel® is a registered trademark of Special Metals Corporation

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.