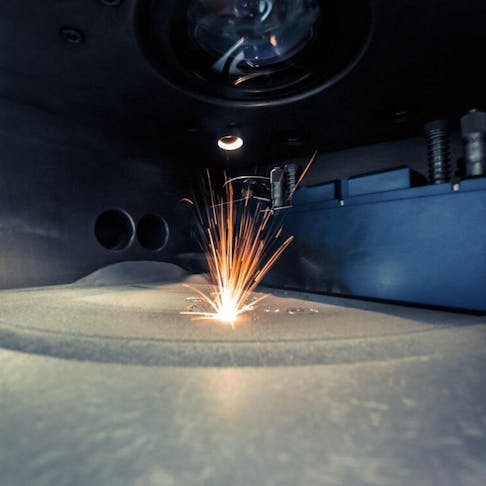

SLM (Selective Laser Melting) and EBM (Electron Beam Melting) are powder bed-fusion 3D printing technologies. A high-energy beam is used to fuse metal powder layer by layer to ultimately print a solid component. SLM has better accuracy and resolution than EBM. EBM, on the other hand, can print faster when compared to single-beam SLM machines. However, there exist SLM machines with 12 high-powered lasers, which significantly improve their speed. EBM has a smaller set of possible materials, specifically refractory and resistant materials.

This article will compare EBM vs. SLM in terms of their system complexity, materials, and printing technologies.

EBM Definition and Comparison to SLM

EBM (Electron Beam Melting) is a powder bed fusion 3D printing technology that is used to manufacture metal parts. Arcam (later bought out by GE) developed this technology in conjunction with the Chalmers University of Technology in 1993. EBM selectively melts a metal or metal alloy powder with a high-energy electron particle beam. This means that instead of energized photons like those in a laser, EBM makes use of energized electrons. The electron beam traces out the cross-section of a part layer and melts the metal particles together. After each layer is melted, the print bed moves down and another layer of metal powder is applied. The EBM printing process must take place in a vacuum to prevent oxidation of the part due to the extremely high temperatures generated by the machine.

EBM has a smaller range of materials, specifically refractory and resistant materials. Compared to EBM, SLM requires an inert gas-filled chamber and can print more accurately.

To learn more, see our guide on Electron Beam Melting.

What Are the Advantages of EBM Compared to SLM?

Listed below are some key advantages of EBM vs. SLM:

- EBM is capable of printing much faster than SLM when compared to a single-beam SLM machine. This is due to the wider beam generated by an electron beam.

- EBM can direct the electron beam at speeds of up to 8000 mm/s. SLM, on the other hand, mimics the speed of EBM by using multiple beams.

What Are the Disadvantages of EBM Compared to SLM?

Listed below are some key disadvantages of EBM vs. SLM:

- EBM requires a vacuum environment. This limits the size of parts that can be built and adds additional complexity to the machine.

- EBM has a smaller range of possible materials to make use of compared to SLM.

SLM Definition and Comparison to EBM

SLM (Selective laser melting) is a powder-bed fusion 3D printing technology used to manufacture metal parts. SLM was first invented in 1995 and was commercialized by SLM solutions. SLM uses a high-powered fiber laser to selectively melt a metal powder. The laser creates a liquid pool of metal wherever it contacts the metal powder. The laser beam traces out the cross-section of a part layer and melts the metal particles together. After each layer, the print bed moves down and another layer of metal powder is applied. SLM uses a build chamber filled with inert gas. SLM is very similar to EBM but makes use of up to 12 high-powered lasers to melt the metal powder instead. It can also use a variety of metals and alloys.

What Are the Advantages of SLM Compared to EBM?

Listed below are some key advantages of SLM vs. EBM:

- With SLM, the operator can adjust the beam width to either favor high speed or high precision.

- SLM can make use of a wider range of materials when compared to EBM.

What Are the Disadvantages of SLM Compared to EBM?

Some key disadvantages of SLM vs. EBM are:

- SLM parts tend to have higher internal stress than EBM. SLM often requires post-build heat treatment to reduce residual stresses.

- A single-beam SLM machine prints slower than an EBM machine.

Comparison Table Between EBM and SLM

Table 1 below lists some of the more common properties of EBM compared to SLM:

| Attribute | EBM | SLM |

|---|---|---|

Attribute Number of beams | EBM 1 - Very quick beam positioning | SLM Machines with 1, 4 and 12 beams are available |

Attribute Beam power | EBM 4500 W | SLM 1000 W |

Attribute Requires vacuum chamber for print build volume | EBM Yes | SLM No - requires inert gas cover |

Attribute Layer height | EBM 70 microns | SLM 20 to 50 microns |

Attribute Parts have isotropic material properties | EBM Yes | SLM Yes |

Attribute Parts need to be cooled after printing | EBM Yes - Often overnight | SLM Yes |

Attribute Parts need support structures | EBM Yes | SLM Yes |

Attribute Largest print volume | EBM 350 OD x 430 H mm (cylinder) | SLM 600 x 600 x 600 mm |

Table 1: EBM vs. SLM Comparison

SLM printers have better layer height resolution than EBM while also having larger build volumes. EBM has a faster beam positioning, meaning it can achieve high speeds without the need for multiple beams.

EBM vs. SLM: Technology Comparison

Both EBM and SLM are powder-bed fusion technologies that make use of a high-powered beam to melt a metal powder. However, EBM uses a beam of electrons, while SLM makes use of multiple high-powered fiber lasers.

EBM vs. SLM: Material Comparison

SLM is able to print a wide range of metals, including most iron, aluminum, nickel, cobalt, and copper-based alloys. EBM, on the other hand, is suitable for a smaller group of raw materials, including Ti6AL4V (a titanium alloy), Inconel® 718 (a nickel alloy), or CoCrMo (a cobalt alloy).

EBM vs. SLM: Product Applications Comparison

EBM is widely used in the aerospace industry to manufacture turbine blades, and in the medical field to produce orthopedic implants. SLM is used to make products in these same industries, but also finds uses in the automotive, construction, and jewelry industries.

EBM vs. SLM: Print Volume Comparison

SLM has a slightly larger available build volume when compared to EBM. This means SLM can print larger singular parts or parts that can fit more nested smaller parts. EBM size is limited by the need to print in a vacuum chamber.

EBM vs. SLM: Surface Finish Comparison

EBM has a slightly worse surface finish when compared to SLM. This is due to EBM’s larger beam width which creates a rougher appearance between each layer. While both SLM and EBM may require post-machining for critical areas, EBM has a noticeably different surface finish.

EBM vs. SLM: Cost Comparison

On average, an entry-level SLM machine can cost upwards of $350,000 whereas an EBM printer can cost from $100,000 to $250,000.

What Are the Mutual Alternatives to EBM and SLM?

Below is a mutual alternative to both EBM and SLM:

- DMLS: DMLS (Direct Metal Laser Sintering) is a powder-bed fusion process that melts metal powder together with a fiber laser, similar to SLM. However, DMLS has better resolution than either EBM or SLM, and typically makes use of multiple lower-energy lasers.

What Are the Similarities Between EBM and SLM?

Listed below are some of the similarities between EBM and SLM:

- Both EBM and SLM are used to print metal parts.

- Both EBM and SLM use energy beams to melt the metal powder into a final part.

What Are the Other Comparisons for EBM Besides SLM?

An alternative 3D printing technology to EBM is:

- EBM vs. DED: DED (Directed-energy deposition) is a metal printing technology that feeds a metal wire to a printing nozzle. The metal is then melted at the nozzle and deposited on the build plate layer by layer, similar to FDM (Fused Deposition Modeling) printing. This produces parts that have isotropic mechanical properties.

What Are the Other Comparisons for SLM Besides EBM?

An alternative 3D printing technology to SLM is:

- SLM vs. SLS: Selective laser sintering can be compared to SLM as both technologies make use of a laser to melt a powdered material one layer at a time into a final part. SLS, however, can only print in plastic. Early metal printers just sintered the metal particles together, as they were unable to create a pool of molten metal like modern-day machines. For more information, see our article on SLM vs. SLS.

Summary

This article summarized the differences between EBM and SLM 3D printing technologies.

To learn more about EBM vs. SLM and to help select the perfect technology for your products, contact a Xometry representative.

Xometry offers a full range of 3D printing services for your project needs. Visit our Instant Quote Engine to get a free, no-obligation quote in minutes.

Copyright and Trademark Notices

- Inconel® is a registered trademark of Huntington Alloys division of Special Metals Corp., Huntington, WV.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.