FDM, which stands for Fused Deposition Modeling, and MJF, an abbreviation for Multi-Jet Fusion, are both types of 3D printing, but they differ in a few ways. In this article, we’ll learn a bit more about them, compare their pros and cons, and answer some frequently asked questions.

FDM Definition and Comparison to MJF

Originally developed and made commercially available in 1988 by Scott Crump, fused deposition modeling is one of the most popular methods of 3D printing today. It works by pumping a thin thermoplastic filament through a heated nozzle and depositing it layer-by-layer to make the part. It’s relatively cheap compared to MJF printing—which is more popular in industrial settings—and is usually easier to get hold of.

The beauty of FDM printers is that they are compatible with filaments from different companies, but MJF printers are limited to materials from HP. FDM does have a couple of drawbacks, too, especially when compared to MJF, which we’ll discuss later. For starters, it produces parts with a low-quality surface finish. Another disadvantage is that FDM printed parts tend to be anisotropic, meaning they’re not as strong in the z-direction because of poor interlayer bonding. We have an article on FDM 3D Printing which we recommend you check out for more information. This is an image of a part made using FDM printing:

What are the Advantages of FDM Compared to MJF?

Listed below are some key advantages of FDM vs. MJF:

- FDM printers are significantly cheaper than MJF printers

- FDM printers can make use of materials from multiple different suppliers. MJF materials, on the other hand, can only be bought from HP (Hewlett Packard).

What are the Disadvantages of FDM Compared to MJF?

Listed below are some key disadvantages of FDM vs. MJF:

- FDM printers produce parts with poor surface finishes

- FDM printed parts have anisotropic material properties in the z-direction. This is due to poor interlayer bonding.

MJF Definition and Comparison to FDM

Multi-jet fusion is another type of 3D printing that was created by the company HP in 2016. It’s quite different from FDM in that it requires several steps before a part is complete, the first of which is adding a thin layer of powder to the printing bed and heating it to just under its sintering temperature. The next part is adding a fusing agent to the powder in the shape of the part’s cross-section. Then a detailing agent is added to the exterior edges to help them be sharper and more crisp.

When that’s done, a source of heat is passed over the plastic, which sinters the particles together wherever the fusing agent is. It’s pretty clear that MJF is more advanced than methods like FDM, and that’s why it’s used a lot in high productions. MJF has some further advantages when compared to FDM, including that its parts come out highly accurate and faster, and that’s partly because you can print more than one part at a time. Also, unlike FDM, MJF parts are isotropic, making them uniform when it comes to their mechanical properties, regardless of direction.

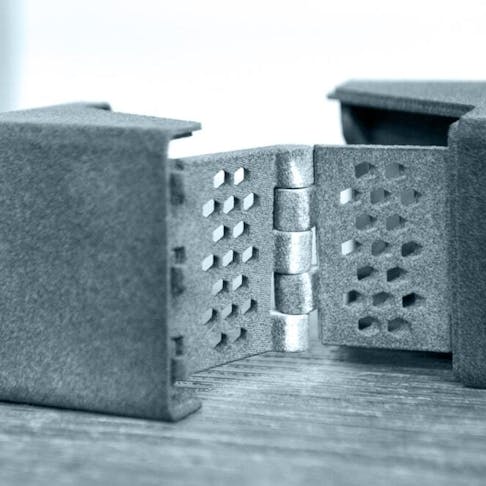

On the other side of the coin, however, MJF printers are among the most expensive types of 3D printers available today—way more expensive than the most advanced FDM printers. They also have a very limited amount of color options, and can only be dyed black, whereas FDM printers can print in lots of different colors. You can check out our article on MJF to learn more about it. The following image shows a part printed using an MJF printer:

What are the Advantages of MJF Compared to FDM?

Listed below are some key advantages of MJF vs. FDM:

- MJF allows for multiple parts per print. It can make more efficient use of the entire build volume due to build-packing techniques.

- MJF parts have isotropic material properties

What are the Disadvantages of MJF Compared to FDM?

Listed below are some key disadvantages of MJF vs. FDM:

- MJF printers are some of the most expensive 3D printers available. They are significantly more expensive than even the most advanced FDM printers.

- MJF parts have very limited color options and can only be dyed black. FDM printers can print parts in a wide array of colors.

Comparison Table Between FDM and MJF

Below, we list some more attributes of both types of additive manufacturing and compare them:

| Attribute | MJF | FDM |

|---|---|---|

Attribute Print resolution | MJF 80 microns | FDM 50 to 500 microns |

Attribute Minimum feature size | MJF 0.25 mm | FDM 1 mm |

Attribute Parts need to cool down after printing | MJF Yes | FDM No |

Attribute It can produce high-strength parts | MJF Yes | FDM Yes |

Attribute Minimum wall thickness | MJF 0.5 mm | FDM 1 mm |

Attribute Print speed | MJF 300 cm3/hour | FDM 10 cm3/hour |

Attribute The parts need support structures | MJF No | FDM Yes |

Attribute Largest print volume | MJF 370 x 274 x 375 mm | FDM 1000 x 1000 x 1000 mm |

FDM vs. MJF Comparisons

MJF parts are high-strength and have better surface quality when compared to FDM parts. MJF can also print significantly faster. FDM printers are cheaper with a wider range of available materials.

Xometry’s Senior Solutions Engineer, Matt Schmidt, says about these methods: “Both FDM and MJF are great platforms for prototype and production. MJF prices are often very competitive with FDM and offer better mechanical part properties, production costs, and surface quality, while FDM can offer a wider material selection, greater part size capability, and colors. They are very different platforms, and the decision is often based upon each platform's unique build capabilities mentioned previously, and whether they fit the customer's need. Cost could be a non-factor if the part does not meet a cosmetic need, for example."

Both FDM and MJF are great platforms for both prototype and production. MJF prices are often very competitive with FDM and offer better mechanical part properties, production costs and surface quality, while FDM can offer a wider material selection, greater part size capability and colors.Matt SchmidtSenior Solutions Engineer

FDM vs. MJF: Technology Comparison

FDM and MJF technologies are very different. The first FDM machine was developed in the 1980s and the fundamental technology has not changed. MJF printers were developed in 2016 and have employed some advanced techniques. FDM printers simply extrude a melted thermoplastic onto the build plate. Whereas MJF makes use of a multi-step process that starts by laying down a thin layer of plastic powder. Then a detailing and fusing agent is applied. Finally, a heat source fuses the material together.

FDM vs. MJF: Material Comparison

FDM printers can make use of a wide range of rigid and flexible, multi-color thermoplastics. An MJF printer, on the other hand, can only make use of a handful of materials such as nylon, polypropylene, and TPU (Thermoplastic Polyurethane). It must be noted that MJF can produce stronger parts than FDM printers.

FDM vs. MJF: Product Applications Comparison

FDM printed parts can be successfully used for a wide range of applications. Examples include: functional and visual prototypes, as well as, limited production runs on mechanical components. MJF parts are stronger and tougher than FDM equivalents. These items can be used for low-volume functional parts as an alternative to injection molding, which is often too expensive to justify low production volumes.

FDM vs. MJF: Print Volume Comparison

FDM printers can have much larger build volumes than MJF printers. However, it must be noted that MJF printers make more efficient use of the available print volume. This can be done by efficiently stacking parts within the entire volume.

FDM vs. MJF: Surface Finish Comparison

FDM parts have a poor surface finish and require post-processing to improve this. MJF parts have a slightly rough matte surface finish that has the appearance of a sand-cast part. MJF parts can be dyed with a black dye to give a uniform finish, as the parts come out of the printer with an uneven gray color.

FDM vs. MJF: Cost Comparison

MJF printers are an industrial manufacturing solution and as such are orders of magnitude more expensive than even the most capable FDM printer. A top-range FDM printer can cost approximately $6,950 whereas MJF printers start at $270,000.

What are the Mutual Alternatives to FDM and MJF?

Despite the benefits of FDM and MJF, there are alternative technologies that can achieve similar results:

- Polyjet: Polyjet printing works by spraying photopolymer drops onto a build plate. A UV light then passes over these droplets to solidify the layer. The next layer is then deposited on the top of the previous one until the part is complete. Polyjet printers have extremely high resolution. They can print parts from many different materials, with different properties and colors in the same part. MJF printers use liquid photopolymers instead of powder-like source materials. An inkjet type head deposits these photopolymer droplets similarly to how the MJF printer deposits its fusing and detailing agents.

What are the Similarities Between FDM and MJF?

Listed below are some of the similarities between FDM and MJF

- Both MJF and FDM can only produce plastic parts. However, specialized FDM filaments have a metal powder in a polymer matrix that needs to be post-processed in a furnace to achieve a truly metal part.

- Both MJF and FDM use heat to bond plastic together to produce final parts

What are the Other Comparisons for FDM Besides MJF?

Listed below are the comparisons for FDM besides MJF

- FDM vs. SLS: Selective laser sintering also manufactures parts from thermoplastics using heat. SLS prints almost exclusively in polyamides, whereas FDM has a much wider range of material options. SLS also melts the plastic with a laser instead of a heated nozzle. SLS printers can produce much higher quality parts when compared to FDM printers. To learn more, see our full guide on SLS vs. FDM.

What are the Other Comparisons for MJF Besides FDM?

Listed below are the comparisons for MJF besides FDM

- MJF vs. SLA: Stereolithography is a printing process that also uses a UV light source to polymerize a photopolymer. SLA can produce parts with higher quality surfaces when compared to parts made using MJF.

FDM vs. MJF Frequently Asked Questions

What’s the Difference in Materials Used?

FDM printers can work with a whole range of materials, including both rigid and flexible thermoplastics of different colors. MJF printers, on the other hand, are restricted to materials like nylon, polypropylene, and thermoplastic polyurethane, but they can make stronger prints than FDM printers.

What’s the Difference in How the Products are Used?

Parts made with an FDM printer can be pretty versatile, so they can be used for things like functional and visual prototypes and mechanical components on limited production runs. MJF parts are usually stronger and tougher, so they’re great for low-volume functional parts as an alternative to injection molding which is way more expensive for low production volumes.

How Much More Expensive is MJF?

Well, you can buy a top-of-the-range FDM printer for around $7,000, but MJF printers usually start at $270,000. The answer is painfully obvious. However, if you need to print FDM or MJF parts, you can use our online quoting engine today and source them directly from Xometry!

How Xometry Can Help

If you have any further questions regarding FDM or MJF, or any 3D printing process for that matter, feel free to reach out to one of our representatives who would be happy to help you. We also offer a huge range of manufacturing services, like CNC machining and laser cutting. Feel free to get a no-obligation quote and get started today. Don’t worry, it’s free.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.