When choosing a manufacturing material, particularly plastic, the technical data sheet will give you a bunch of useful information to help in your selection. The heat deflection temperature (HDT) is one such tidbit, and it’s an important one to know if your product needs to keep its shape and size under pressure.

What is Heat Deflection Temperature?

A material’s HDT is the temperature at which it starts to deform when it’s put under a specific load at high heat. It measures the plastic’s ability to stay stiff or rigid in these circumstances. High HDT plastics will stay more rigid in higher heats, and low HDT ones, not so much. And yes, this is only relevant to polymers and plastics, so metals will have to sit this one out (they have their own versions, like hot hardness and creep tests).

HDT is valuable (a must, in fact) for the engineering, design, and manufacturing of plastic products (or those with any parts made of plastic) in many industries, including:

- Packaging

- Aerospace

- Automotive

- Electronic

- Medical

- Consumer goods

- Construction industry

- Injection-molding

In packaging, containers at the grocery store, post office, and even at home, are stacked and squashed—and sometimes in heat—but they can’t warp under pressure. The same goes for vehicle parts, like dashboards. A car often sits in direct sunlight for hours on end, but it would be a total disaster if the dash sunk in when you put your bag or phone on it. In injection molding, a material’s HDT is one of the factors that will determine the process cycle time. It’s also a big decider in whether or not a plastic is suitable for use as a structural component, as these understandably have a pretty tough job.

What Is the Importance of Heat Deflection Temperature (HDT)?

HDT is a helpful gauge for determining the temperature at which a material cannot be used for structural applications. This value can be used to compare materials with one another. It also helps indicate how a molded plastic part will perform when placed under mechanical load and exposed to heat. HDT is an important property in the injection molding industry. It can give insight into the polymer’s moldability.

The ejection stage of any injection molding process puts a load on the freshly molded object. The material must be stiff enough that the ejector pins will properly force it out of the mold. The relative difference between two materials’ HDT values can help you decide on the proper cooling rate and temperature. The ejector pins will sink into soft, flexible plastic that is still above its HDT. However, below that temperature, it gets hard and is simpler to push out of the mold. A higher HDT enables a faster molding process.

How Is Heat Deflection Temperature (HDT) Related to 3D Printing?

Heat Deflection Temperature (HDT) is a critical property for 3D printing materials, especially when using fused deposition modeling (FDM) and Polyjet devices. It becomes an important consideration because the material is heated and melted to create a 3D object. During the printing process, the material is subjected to high temperatures. It must maintain its shape and structural integrity so that the final product is durable and looks right.

Different 3D printing materials have different HDT values. Your choice of material depends on the specific application and operating conditions. For example, if a 3D-printed part will be used in high-temperature environments, it must have a high HDT value to maintain its shape and properties.

To learn more, see our guide on How 3D Printing Works.

How To Measure Heat Deflection Temperature (HDT)?

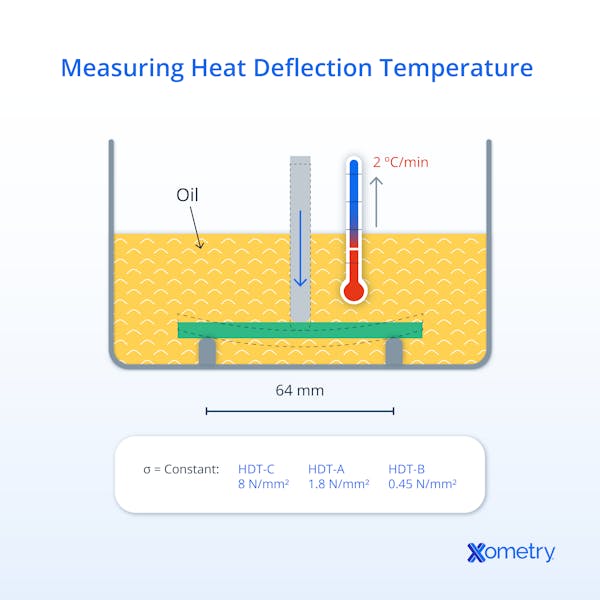

To work out a material’s HDT, we need heating, loading, and measuring systems—all of which are provided by the HDT test equipment/apparatus (pictured below). The standard measuring system for HDT is the American Society for Testing and Materials (ASTM) D 648—which is comparable to the ISO 75 international standard.

The HDT measuring process consists of the following 4 steps:

- The sample is prepped and loaded on the machine in a three-point bending configuration, meaning it’s supported at its two ends so that pressure can be applied in the middle.

- A constant bending stress (either 0.46 or 1.8 MPa, depending on what you’re testing) is applied to said middle.

- A mineral or silicone oil that won’t affect the plastic is used as the heat transfer, and its temperature is gradually increased at a controlled rate of 2°C/min (±0.2°C/min).

- The sample is monitored throughout all stages and temps, and when it deforms by 0.25 mm, we have the HDT.

What Are the Common Loads Used in Heat Deflection Temperature (HDT)?

To get a little more technical, the standard states that a material’s HDT is the temperature at which a bar measuring 127 x 13 x 12 mm (we’ll call this the “sample”) deflects by 0.25 mm when put under a centered standard flexural stress of either:

- 0.46 MPa (67 psi): This is used on soft plastics, like polyethylene (PE), or low-density PE, and other polymers for general use.

- 1.8 MPa (264 psi): For stronger and more durable thermoplastics/thermosetting materials for heavy-duty use, such as polyether ether ketone (PEEK), polycarbonate (PC), and epoxy resins.

The testing method for both of these is exactly the same, apart from the load amount. The higher 1.8 MPa load will make the material deform at a lower temperature than the 0.46 MPa one. Sometimes, higher 5.0 MPa (725 psi) or 8.0 MPa (1160 psi) loads are tested but as this is rare, we’ll just stick to the two common ones.

1. 0.46 MPa (67 psi)

The 0.46 MPa heat deflection method is the most common version of the test for softer plastic grades like PE and LDPE. The heated sample is subjected to a load of 0.46 MPa (67 psi), and the temperature is gradually increased at a specified rate. The deflection of the sample is measured at various temperatures, and the temperature at which the sample deflects 0.25 mm under the load of 0.46 MPa (67 psi) is recorded as the HDT. Note that 0.25 mm is an arbitrary amount and has no significant value in and of itself.

2. 1.8 MPa (264 psi)

The 1.8 MPa HDT test is very similar to the 0.46 MPa test, with the only difference being the load that is applied to the specimen. The 1.8 MPa (264 psi) HDT test is typically used to evaluate the thermal properties of high-performance thermoplastics and thermosetting materials designed for high strength and rigidity at elevated temperatures. Materials that are tested with this method include PC, PEEK, and epoxy resins.

Heat deflection temperature is one of a few key material properties that describe how a material behaves as it is heated. It is the temperature at which the material deforms a measured amount under a static force. It can be useful in determining the temperature at which a material in a structural part will begin to warp.Christian Tsu-RaunTeam Lead, Manual Quoting

What Device Is Used in Measuring Heat Deflection Temperature (HDT)?

The equipment used to test this value is called an HDT tester or an HDT apparatus. It typically consists of a heating system to raise the temperature of the sample, a loading system to apply force to the sample, and a measuring system to determine the deflection of the sample at various temperatures.

The HDT test setup consists of a rectangular-shaped sample of a specific size and thickness that is loaded in a three-point bending configuration. The sample is heated at a constant rate, and the temperature at which the sample begins to deform under the specified load is recorded as the HDT.

What Is the Standard Measuring for Heat Deflection Temperature (HDT) in ASTM?

ASTM D 648, which is comparable to ISO 75, is the ASTM (American Society for Testing and Materials) standard for measuring HDT.

To learn more, see our full guide on ASTM International.

What Are the Examples of Heat Deflection Temperatures (HDT) of Different Materials?

The below table will give you an idea of the HDT of some common polymers, although these are averages and might not apply to all the different grades of each material. We’ve also included the melting point of each for reference.

| Material | HDT at 0.46 MPa (°C) | HDT at 1.8 MPa (°C) | Melting Point (°C) |

|---|---|---|---|

Material ABS | HDT at 0.46 MPa (°C) 98 | HDT at 1.8 MPa (°C) 88 | Melting Point (°C) - |

Material Acrylic | HDT at 0.46 MPa (°C) 95 | HDT at 1.8 MPa (°C) 85 | Melting Point (°C) - |

Material Nylon 6 | HDT at 0.46 MPa (°C) 160 | HDT at 1.8 MPa (°C) 60 | Melting Point (°C) 220 |

Material Polycarbonate | HDT at 0.46 MPa (°C) 140 | HDT at 1.8 MPa (°C) 130 | Melting Point (°C) - |

Material Polyethylene | HDT at 0.46 MPa (°C) 85 | HDT at 1.8 MPa (°C) 60 | Melting Point (°C) 130 |

Material PET | HDT at 0.46 MPa (°C) 70 | HDT at 1.8 MPa (°C) 65 | Melting Point (°C) 250 |

Material Polypropylene | HDT at 0.46 MPa (°C) 100 | HDT at 1.8 MPa (°C) 70 | Melting Point (°C) 160 |

Material Polystyrene (PS) | HDT at 0.46 MPa (°C) 95 | HDT at 1.8 MPa (°C) 85 | Melting Point (°C) - |

HDT of Common Polymers

Where Does Heat Deflection Temperature (HDT) Commonly Apply?

HDT is a well-known property and gets used in the engineering, design, and production of items with thermoplastic components. A lot of industries use this value to select the correct polymer for the job. Some of the top industries for which HDT is relevant include: packaging, aerospace, automotive, electronic, medical, and injection-molding industries.

What Are the Factors That Impact the Heat Deflection Temperature (HDT)?

Several things can affect the test’s outcome (which is why there are standards that should be followed for consistent results), such as:

1. The Time of Exposure to Elevated Temperature

The HDT is influenced by the length of time a material is exposed to elevated temperatures. The longer the material is heated, the more likely it is to deform under load.

2. The Part Geometry

The geometry of the test specimen plays a crucial role in determining the HDT. The thickness and shape of the specimen can affect the rate of heat transfer and the distribution of stress within the sample during the test.

3. The Rate of Temperature Increase

The rate of temperature increase during the test affects the HDT. If temperatures rise slowly, the HDT may be higher while a speedy rate of heating can result in a lower HDT. The rate of temperature change can also affect the mechanical properties of the material, including the modulus of elasticity, tensile strength, and elongation at break.

Frequently Asked Questions About Heat Deflection Temperature

Is HDT important in 3D printing?

It is for two main reasons. The first and more obvious one is if the part you’re 3D printing will be subjected to loads in high temperatures, the HDT will help you decide the right material to use. The second is that 3D printing in itself subjects the filament to high heat—particularly with fused deposition modeling, where the material is pushed through a heated nozzle. Plastics with higher HDTs won’t be as prone to sagging during extrusion. In any event, most machines nowadays have built-in cooling fans, and there are ways around sagging if you’re set on using a plastic with a lower HDT (i.e., 3D printing supports).

What Is the Difference Between Heat Deflection Temperature and Glass Transition Temperature?

HDT is a macroscopic measurement of a material’s stiffness as temperature increases and the point at which it deforms under load. The glass transition temperature (Tg) marks the point where an amorphous (or semi-crystalline) polymer—like PC, PS, and polymethyl methacrylate—transitions from a rigid to a softened state as molecular chain movements "freeze." Unlike crystalline materials, amorphous polymers don’t have a defined melting point; instead, they soften over a range of temperatures and are characterized by their Tg. The Tg is typically higher than the HDT, and is measured with DSC (differential scanning calorimetry) or DMA (dynamic mechanical analysis).

Is HDT known by any other names?

Yes, and we’re often asked by customers why they can’t find this stat on the data sheet. It’s also referred to as the deflection temperature under load (DTUL), heat deflection temperature under load (HDTUL), or heat distortion temperature.

What Is the Heat Deflection Temperature (HDT) of Nylon?

The heat deflection temperature (HDT) of Nylon will vary for different loads. The HDT is typically determined at a specific load, and increasing the load will result in a lower HDT.

For example, the HDT of unfilled and unmodified Nylon 6 and Nylon 6/6 at a load of 1.8 MPa (264 psi) can be in the range of 70-120°C. If the load is reduced to 0.46 MPa (67 psi), the HDT jumps into the range of 115-155°C.

It's important to note that HDT is just one of several factors to consider when selecting a material. The actual performance of Nylon in a given situation will depend on various factors such as the specific grade of Nylon, the geometry of the part, and the operating conditions beyond just the load and temperature.

Is Heat Deflection Temperature (HDT) Only Applied in Plastics?

Yes. Heat deflection temperature is a thermal property that’s unique to polymers and plastics.

Can Heat Deflection Temperature (HDT) Be Also Applied to Steel?

No, HDT cannot be applied to steel. The heat deflection temperature (HDT) is a property that relates specifically to polymers and plastics. There are, however, other thermal properties that can provide valuable insights into how metals behave.

What Is the Difference Between Heat Deflection Temperature and Glass Transition Temperature?

Amorphous materials' glass transition temperature (Tg) or melting temperature (Tm) are related to their heat deflection temperature. The HDT is a helpful indicator of the temperature over which the material cannot be used for structural purposes. HDT and Tg (or Tm) are, however, not interchangeable terms. The HDT is a macroscopic measurement of a material’s "stiffness" as the temperature increases, whereas the Tg specifies the temperature at which vitrification or glassification occurs (i.e. when the movements of molecular chain segments (kinetic units) begin to "freeze").

The two characteristics are usually closely related. Fillers and reinforcements, however, significantly alter the HDT since the former softens the polymeric component while the latter stiffens it. Depending on the type and amount of filler/fiber used, filled and unfilled polymers can have quite different HDTs. Plasticizers have similar impacts on both attributes. The HDT is frequently a better indicator of the temperature application limit for structural applications than is the Tg or Tm.

How Xometry Can Help

Whether you’re in the process of choosing the best material for your product, or need to know the HDT of a material you’re already working with, we’re just a call/message away—feel free to get in touch with one of our representatives. You can also get a quick and free, no-obligation quote on any of our manufacturing services—of which there are many, including 3D printing, plastic injection molding, and CNC machining.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.