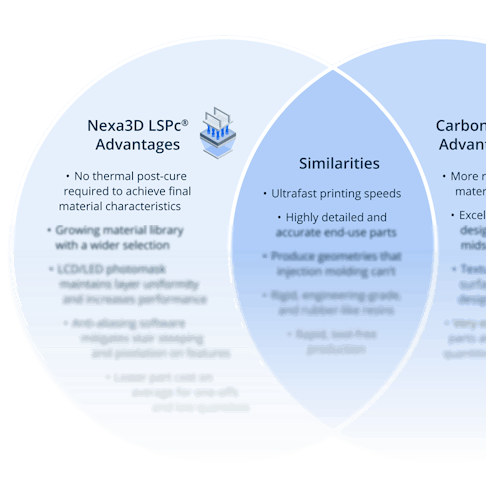

Infographic: Production 3D Printing (Nexa3D LSPc vs. Carbon DLS)

Our Nexa3D LSPc 3D printing process is a great option for low-volume plastic production orders. See how it compares to another additive low-volume production option, Carbon DLS.

Nexa3D's Lubricant Sublayer Photo-curing (LSPc®) technology provides extremely fast and accurate 3D printing in a range of end-use materials. Combined with our Carbon DLS™ offering, customers have multiple options for their low-volume production needs. These technologies can be a viable alternative to injection molding and urethane casting.

This venn-diagram demonstrates the distinct advantages and similarities of these two production photopolymer printing processes.

About Xometry

Xometry offers instant pricing for manufacturing, including precision CNC machining, 3D printing, sheet metal fabrication, injection molding, and urethane casting services. Xometry also provides live engineering support from our team of experts.Upload a 3D CAD fileto get an instant quote.