PLA (polylactic acid) filament is one of the most commonly used in fused deposition modeling (FDM) 3D printing because it’s easy to work with and looks great. In the history of plastics, PLA is the OG (well, one of them). It was invented in 1938 by DuPont chemist Wallace Carothers (who also, coincidentally, invented nylon), but took quite a long time to become mainstream. In the ‘50s, large manufacturing product materials companies started doing more in-depth research on it, and by the ‘90s, PLA was on the market commercially. It was first adopted as a biodegradable PET alternative and has since been used for everything from packaging and disposable cutlery to appliances and devices. When 3D printers emerged in the late '00s, PLA was one of the first filament materials used and, today, it accounts for more than 40% of the plastics used in additive manufacturing.

What is PLA 3D Printing Filament?

PLA is a thermoplastic polymer made by fermenting plant products like sugarcane or cornstarch to produce lactic acid, which is then polymerized into PLA, often using lactide. It can then be mixed with nucleating agents or plasticizers (i.e., polyethylene glycol) to change its properties. For extra benefits, it can also be mixed with other materials like wood fibers, carbon, metal flakes, graphene, etc. It’s then extruded into filament or fiber. The PLAs with simpler ingredient lists are known as PLA, while the ones chock full of enhancers are referred to as PLA+.

- PLA: Close to the pure polymer but may contain limited amounts of additives to modify various properties, including intramolecular flexibility, melt viscosity, and color or visual properties.

- PLA+: Likely to contain significant quantities of a wide range of additives. These include carbon fiber for model stability, stiffness, and increased UTS (ultimate tensile strength); wood fiber for cosmetic effect; graphene for stiffness and increased UTS; and metal particles for cosmetic effect.

For more information on their similarities, differences, and uses, have a look at our guide: PLA vs. PLA+ 3D Printing.

Among PLA’s desirable properties is its intra-layer bonding, which allows newly extruded plastic to bond very well with plastic that has been recently cooled. The strands and layers blend effortlessly together for a smooth (and pretty) surface, and this doesn’t change much even if you switch up the machine’s settings. It also has a good tolerance to a range of extruding temperatures so that you can use it on many different machines. This makes it super easy to print with and a great starter 3D printing filament for those without much experience.

You can use PLA for items that need to be attractive, but not necessarily long-lasting. The material can’t take a lot of stress, so you wouldn’t want to make machine parts, engineering test pieces, or bearing-type components from it. It can’t survive being left outdoors and doesn’t hold up well when faced with water, chemicals, or abrasion. Also, just because it’s made from “green” materials, that doesn’t automatically make it eco-friendly. PLA needs to be separately recycled, and it’s only biodegradable if commercially composted.

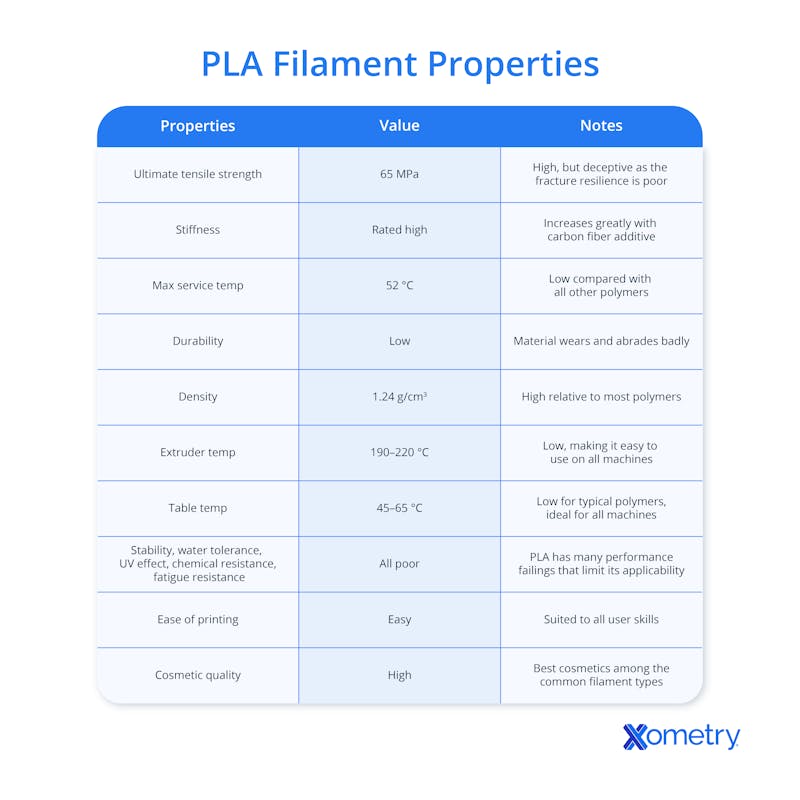

Properties

All the important properties of PLA filament are listed in the table below.

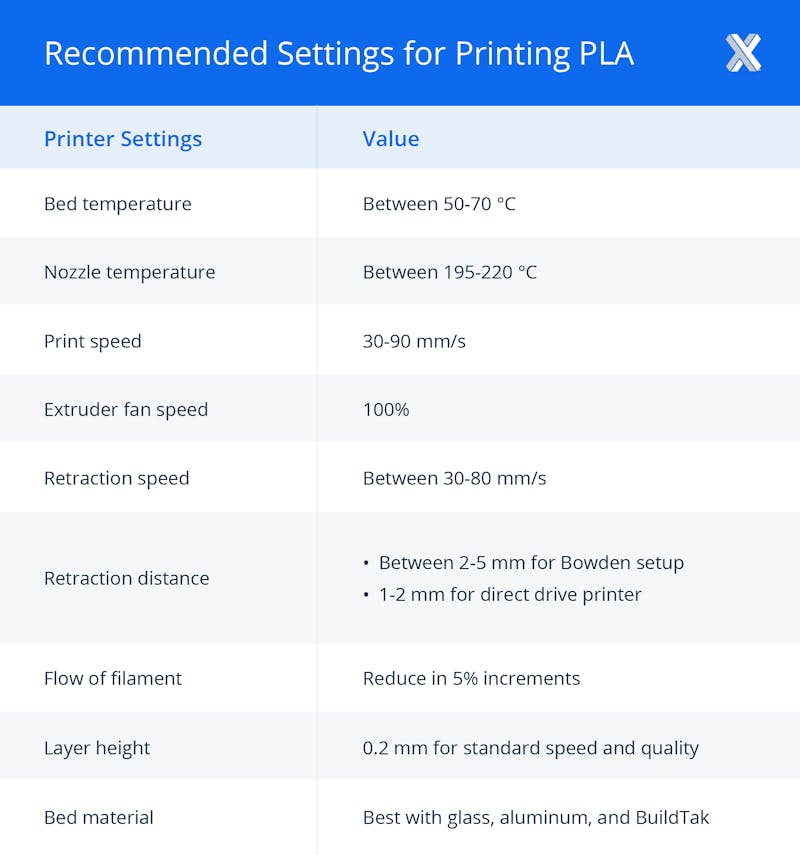

Best Settings for PLA 3D Printing Filament

To get the best results when 3D printing with PLA filament, you’ll want to make sure your printer has the right settings (although, to be fair, this material is pretty forgiving of settings). When melting it, the machine should be increased from a low setting in small increments, while being careful not to over- or under-feed the filament. You don’t particularly need a heated bed with this filament; the only thing that it would help with is easier removal of the final print. To make your piece stronger, you’ll want a wall thickness of 1.2–2.2mm, but for items with a solely cosmetic purpose, this can be 0.8mm. Getting the wall thickness just right is probably the only thing that will need a little skill. The settings we recommend for working with PLA filament are listed in the table below.

PLA vs. ABS vs. PETG

These three filament types have quite a few differences meaning that they can’t really be used interchangeably. The below table breaks down their pros and cons, but for more information, you can head on over to our in-depth guides on 3D printing with PLA vs. ABS and PETG vs. PLA.

| Comparison | PLA | ABS | PETG |

|---|---|---|---|

Comparison Strength | PLA Poor | ABS Excellent | PETG Great |

Comparison Ultimate tensile strength | PLA Good | ABS Lower than PLA | PETG Lower than PLA (tougher and more flexible) |

Comparison Durability | PLA Poor (brittle, degrades over time) | ABS Good | PETG Good |

Comparison Resilience | PLA Poor | ABS Excellent | PETG Good |

Comparison Elasticity | PLA Poor | ABS Good | PETG Moderate |

Comparison Shock-, fracture-, and impact-resistance | PLA Poor | ABS Excellent | PETG Good |

Comparison Aesthetic appeal | PLA Excellent | ABS Poor (often has rough surface finish) | PETG Moderate (can be glossy but shows stringing) |

Comparison Transparency | PLA Moderate (can be semi-transparent) | ABS Poor (typically opaque) | PETG Excellent (can make semi-transparent or clear parts) |

Comparison Intra-layer fusion | PLA Excellent | ABS Poor (can warp) | PETG Excellent |

Comparison Water resistance | PLA Poor | ABS Good | PETG Excellent (practically hygroscopic) |

Comparison UV tolerance | PLA Poor | ABS Poor | PETG Good |

Comparison Ease of use | PLA Easy | ABS Hard | PETG Moderate |

Comparison Skill required | PLA Low | ABS High | PETG Moderate |

Comparison Requirements | PLA Not many (hardly any warping, can print at low temperatures) | ABS Higher/controlled nozzle temperatures, enclosed environment, i.e. a chamber | PETG Higher nozzle temperature (often not possible with budget printers) |

Comparison Applications | PLA Decorative items, prototypes | ABS Structural and moving parts, bearing/rubbing surfaces | PETG Mechanical and functional parts, outdoor use |

Comparison Cost | PLA Cheapest ($15–20 per kg) | ABS Moderate ($20–30 per kg) | PETG Moderate ($20–30 per kg) |

PLA vs. ABS vs. PETG

How Xometry Can Help

Xometry provides a wide range of manufacturing services, including custom 3D printed parts for all of your prototyping and production needs. To learn more about PLA filament and if it is the right material for your application, contact a Xometry representative, or go straight to our PLA 3D Printing service to start a new instant quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.