Both PolyJet and MultiJet (MJP) 3D printing are additive manufacturing methods that build parts by depositing and curing photopolymers that react to ultraviolet (UV) light. They can both be used for proof of concept and functional prototypes and can make complex parts, some of which are often found in the dental and medical sectors, specifically for things like molds for crowns and braces. Despite these commonalities, these two processes have some key differences that make one able to print with composite materials and the other better for small-to-medium production. Read on to find out which.

PolyJet Definition and Comparison to Multijet

First developed in 2000 by Objet Geometries and acquired by Stratasys, who now owns its trademark rights, PolyJet printing works similarly to an inkjet printer. “PolyJet is a process by which material is jetted onto a print plate layer by layer,” says Christian Tsu-Raun, the Team Lead at Xometry’s Manual Quoting. “It’s relatively slow but very accurate, and good for small, nonfunctional prototypes.” In the process, tiny drops of photopolymers are released in areas that have been programmed beforehand to create 2D layers on top of each other. It then uses a UV light to harden those drops and set each layer’s shape. PolyJet is known for retaining a high level of detail and can print in layers as thin as 16 microns; however, Xometry typically prints at a layer height of 25 microns.

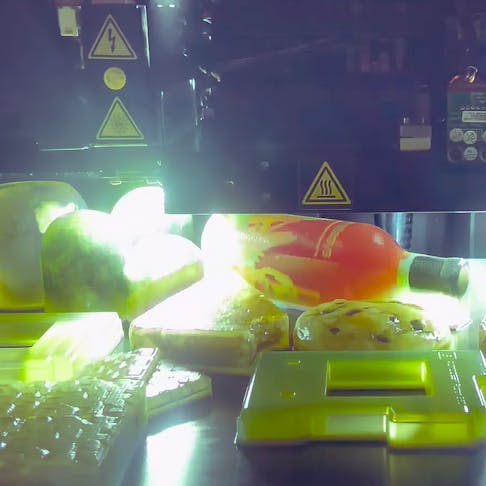

The photopolymer will only become dimensionally stable when it’s cured. That’s why support materials are laid down at the same time as the main polymer part, which enhances its dimensional accuracy and provides a sort of frame for the photopolymer to be held in until it’s cured. These support materials resemble a slightly rigid gel-like substance encasing the part by the end of the process. When the part is finished, it’s washed with a water jet and, soaked in a chemical solution to remove the supports, then left to dry. The following is an image of a Xometry rainbow logo made with PolyJet printing:

PolyJet is a method that allows you to print using various materials in one job, and parts will usually maintain their material properties after being post-processed. Materials of different properties can even be mixed simultaneously to simulate different material properties, such as mixing different ratios of rubber-like with rigid photopolymers to create pieces with different durometer ranges. The downsides to using this technique, though, are that the parts tend to be very fragile and fine features can easily be broken during or after post-processing. We do not recommend using PolyJet for end-use parts. The printing and post-processing can also take longer compared with MJP, which can affect overall cost. Learn more about PolyJet 3D printing in our dedicated article.

PolyJet is a process by which material is jetted onto a print plate layer by layer. It is relatively slow but very accurate. It's good for small, nonfunctional prototypes.Christian Tsu-RaunTeam Lead, Manual Quoting

What are the Advantages of PolyJet Compared to Multijet?

Listed below are the advantages of PolyJet vs. Multijet:

- Parts composed of several different materials can be printed in one job using PolyJet.

- PolyJet-printed parts can maintain their material properties after post-processing.

What are the Disadvantages of PolyJet Compared to Multijet?

Listed below are the disadvantages of PolyJet with respect to Multijet:

- PolyJet has reduced surface quality in areas where support material is used.

- PolyJet-printed parts have inaccurate printing at sharp edges leading to these edges becoming rounded.

Multijet Definition and Comparison to PolyJet

MultiJet’s creation is attributed to the company 3D Systems, and it’s another type of 3D printing that works kind of like an inkjet printer. Like the first method we discussed, MJP uses a printing head that creates parts layer by layer using either UV-curable photopolymer or casting wax droplets. It can also create layer thicknesses of as small as 16 microns, but compared to PolyJet, it has limited multi-material mixing capabilities, if any at all, depending on the machine. Support structures for this technique are made from paraffin wax, so when a part is finished, it’s put in an oven or placed into a warm mineral oil bath to melt the wax away. Post-processing MJP parts is generally easier than PolyJet printing, but care must be taken when melting the wax to prevent the heat from affecting the properties of the main build material.

The potential downsides of using MJP include the fact that you cannot produce intricate full-color components or mix a range of materials such as rubber-likes, rigid, and transparent materials simultaneously to simulate different material properties as you can with PolyJet printing. Also, MJP parts run the risk of their material properties changing during post-processing if proper procedures and care are not taken.

What are the Advantages of Multijet Compared to PolyJet?

An advantage of Multijet over PolyJet is in its post-processing. Multijet effortlessly completes post-processing by placing completed parts in an oven for support material to melt away.

What are the Disadvantages of Multijet Compared to PolyJet?

Listed below are the disadvantages of Multijet compared to PolyJet:

- Limitations in part to aesthetics exist in Multijet-printed parts due to single-color and single-material print jobs.

- Multijet-printed parts tend to have altered material properties as a result of post-processing.

Comparison Table Between PolyJet and Multijet

The table below compares the attributes of PolyJet and Multijet:

| Attribute | PolyJet | Multijet |

|---|---|---|

Attribute Uses photopolymer | PolyJet TRUE | Multijet TRUE |

Attribute Prints composite material parts | PolyJet TRUE | Multijet FALSE |

Attribute Easy postprocessing | PolyJet FALSE | Multijet TRUE |

Attribute Used for functional prototypes | PolyJet TRUE | Multijet TRUE |

Attribute Used for small-to-medium production volumes | PolyJet FALSE | Multijet TRUE |

Attribute Need for support materials | PolyJet TRUE | Multijet TRUE |

Attribute Can form complex and detailed geometries | PolyJet TRUE | Multijet TRUE |

Attribute Costly | PolyJet TRUE | Multijet TRUE |

PolyJet vs. Multijet Comparison

Both PolyJet and Multijet is capable of printing complex and detailed parts - parts that wouldn’t be manufacturable using traditional methods. While the two processes are quite similar, two of the three main differences are the materials used for printing and the ease of post-processing. PolyJet can print composite parts in one job but requires more post-processing methods than Multijet printed parts.

PolyJet vs. Multijet: Technology Comparison

PolyJet and Multijet systems use similar technologies and processes. Both use UV-sensitive photopolymers and a UV curing system. While not significantly different, the two methods differ in the number of print heads present in the system. PolyJet can have two or more heads, while Multijet can have a maximum of two.

PolyJet vs. Multijet: Material Comparison

In PolyJet systems, multiple materials can be combined into a single raw material with characteristics from all its constituent materials. These composite materials are called “digital materials.” They enable the printing of a single part with different material properties in one build.

Materials used in Multijet systems are photopolymers. Multijet-printed parts are necessarily a single color and are composed of a single material. If composite materials are needed, whether for aesthetics or functional reasons, PolyJet may be the better option.

PolyJet vs. Multijet: Product Applications Comparison

PolyJet and Multijet both produce exceptionally detailed and functional prototypes and parts. This level of detail makes PolyJet and Multijet ideal at every step of the design process. PolyJet and Multijet-printed parts are commonly found in the dental and medical industries where they are used to create dental molds for crowns and braces.

PolyJet vs. Multijet: Print Volume Comparison

Print volumes of PolyJet vs. Multijet don’t differ much. Depending on the system used, PolyJet can have volumes up to 260 x 200 x 200 mm and Multijet systems can have volumes up to 294 x 211 x 144 mm. If larger parts are needed, parts can be printed in pieces and then assembled afterward.

PolyJet vs. Multijet: Surface Finish Comparison

Surface finishes of PolyJet vs. Multijet-printed parts don’t significantly differ. Because of the precise resolutions and layer thicknesses of both PolyJet and Multijet, surfaces on completed parts are smooth. Occasionally, rough surfaces may be present in more complex geometric areas but can easily be smoothed out with an appropriate post-process.

PolyJet vs. Multijet: Cost Comparison

PolyJet and Multijet systems can be expensive compared to other forms of 3D printing. PolyJet printers start as low as $6,000 and go as high as $75,000 for more advanced systems. Multijet printers are similarly priced and average around $43,000.

What are the Mutual Alternatives to PolyJet and Multijet?

An alternative to both PolyJet and Multijet is

- DLP: Digital light processing (DLP) also uses cured liquid photopolymers to build parts. Curing is completed by a projector in DLP. The primary difference between DLP and PolyJet / Multijet is that parts are printed upside down, and the liquid photopolymer is deposited from a tank underneath the build platform. Despite these differences, DLP rivals PolyJet and Multijet in terms of resolution, precision, and cost-effectiveness.

What are the Similarities Between PolyJet and Multijet?

Similarities between PolyJet and Multijet include:

- Both use liquid photopolymers cured by UV lamps to build parts.

- Both can be used for proof-of-concept and functional prototypes.

- Both can print complex geometries that otherwise would not be manufacturable using traditional methods.

What are the Other Comparisons for PolyJet Besides Multijet?.

Besides Multijet, another alternative to PolyJet is:

- PolyJet vs. SLA: SLA is a comparable alternative to Polyjet since it can be used for both functional prototypes and parts. The difference between PolyJet and SLA is that SLA has equivalent, if not better resolution than PolyJet, depending on the system. It offers the highest resolution of any form of 3D printing and it can therefore also be used for molds, tooling, patterns, and the production of textured surfaces.

What are the Other Comparisons to Multijet Besides PolyJet Besides?

Besides PolyJet, another potential alternative to multijet is:

- Multijet vs. MJF: Multi-Jet Fusion (MJF) is comparable to Multijet since it is excellent at producing complex geometries with exceptional surface finishes. The difference between Multijet and MJF is that MJF works by using a polymer powder and a fusing mechanism (ink agents and infrared frequencies) to cure parts.

Frequently Asked Questions on PolyJet vs. MultiJet

How much do these machines cost?

As these are high-end machines meant for industrial settings, they do not come cheap. PolyJet printers can run anywhere between $150,000 and $500,000, and MJP machines are quite similar, typically ranging from $150,000 to $400,000. This is why services like those Xometry offers are useful, as you can take advantage of these high-end systems without the upfront investment setting up and running them entails.

Are there any alternatives to PolyJet and MJP?

Carbon DLS™ (Digital Light Synthesis™) is a comparable 3D printing method that also produces high-resolution and precise parts. Like PolyJet and MJP, DLS cures liquid photopolymers to build new parts, but it does so with projected light and a continuous liquid interface for production. In addition, DLS prints seamless parts continuously, upside down.

What’s the difference between PolyJet and SLA?

SLA (stereolithography) 3D printing uses a laser to cure liquid resin into solid parts. It’s good for making functional prototypes and parts, and, depending on the specific machine and setup, it could have even better resolution than PolyJet. SLA prints are high-quality and often made into molds and tooling, such as master patterns for casting applications.

What’s the difference between MJP and MJF?

Both methods seem similar even by the name, with MJF being an abbreviation for multi-jet fusion. “MJF is a process by which a fusing agent is applied to successive layers of powdered material,” Tsu-Raun tells us. “It is relatively fast and produces parts in production thermoplastics, but is less accurate than PolyJet." The method is also really good at making complex shapes and durable, end-use parts. One of the main differences is that MJF uses a polymer powder and a fusing system to produce parts, allowing it to work in popular engineering materials such as Nylon, TPU, and Polypropylene.

How Xometry Can Help

Xometry offers instant access to a variety of 3D printing technologies, including PolyJet, Multi-Jet Fusion, SLA, and more! Best of all, we offer instant quoting and feedback through the Xometry Instant Quoting Engine®, allowing you to quickly get high-quality 3D-printed parts in your hands.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.