When it comes to 3D printing, you’re only limited by your imagination. Nowadays, it’s easier to ask the question, “What can’t you print using this process?” rather than listing the long and never-ending list of what can be produced. 3D printing is able to make simple tools, pump out full-blown architectural models, and even create prosthetics.

Not all printing needs will be the same, and there are actually quite a few methods you can choose from. For instance, at Xometry, we offer nine unique 3D printing processes, and are always aiming to add more. Each of these processes has its own pros and cons. Some are better for working with metal, other styles cure with lasers, and some are built for beginners interested in trying printing for the first time. Up ahead, learn about the different types of 3D printing and get an idea of the strengths and weaknesses of each.

1. Polyjet Printing

While 3D printers may seem pretty futuristic, PolyJet printing is the closest thing to the good ol’ fashioned inkjet printing you’re probably most familiar with. These machines use print heads to sprinkle tiny droplets of photopolymer resin onto a build plate, which then get hardened by a UV light in layers. Xometry’s PolyJet machines are capable of full-color and multi-material prints, making them ideal for creating lifelike models and visual prototypes. Be warned, though, PolyJet materials are not known for durability and are not suitable for end-use components.

Polyjet is best suited for smaller parts with small features. It is very accurate, but the materials tend to be less durable.Christian Tsu-RaunTeam Lead, Manual Quoting

The photo below shows one of our PolyJet printers creating full-color parts:

Xometry's PolyJet 3D printer creating multi-color parts.

This table shows the materials a polyjet printer can use, what it can make, and its strengths.

| Materials | Strengths | Common Applications | Dimensional Accuracy |

|---|---|---|---|

Materials Rigid photopolymers, Shore A Rubber-Likes, Clear photopolymer | Strengths High resolution, Multi-material, full-color | Common Applications Overmold prototypes, full-color concept models, educational models | Dimensional Accuracy +/- 0.004” for the first inch, plus +/- 0.002” for every inch thereafter |

2. Fused Deposition Modeling (FDM)

Fused deposition modeling (FDM) machines can be found anywhere from a desk of a hobbyist, to the manufacturing floors of production facilities like Xometry's. This popular method involves moving a plastic filament through a heated nozzle to melt it and build up a part layer by layer until the final product is finished. There are many different filament materials to choose from for FDM printing, whether you’re after a more rigid plastic or bendy thermoplastic elastomer.

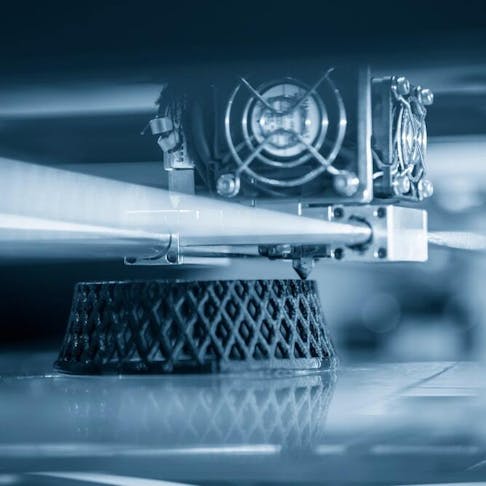

The image below shows one of Xometry's industrial printers capable of producing parts up to three feet in length:

One of Xometry’s many industrial FDM 3D printers

This table shares the materials a fused deposition modeling printer uses, what it can make, and its advantages compared to other printers.

| Materials | Strengths | Common Applications | Dimensional Accuracy |

|---|---|---|---|

Materials ABS, PLA, PC, ULTEM, and more | Strengths Low-cost, large print volumes, material variety | Common Applications Prototyping, Hobbyist parts, Manufacturing Jigs | Dimensional Accuracy +/- a single build layer thickness for the first inch and +/- .002” for every inch thereafter |

3. Stereolithography (SLA)

Stereolithography (SLA) was the first kind of 3D printing that everyday people could get their hands on. This printer uses a high-powered laser to cure liquid photopolymer on its build plate. The laser zips around in the shape of the part’s cross-section, curing it and getting it ready for the next layer. It works with a process called polymerization to build the item you’ve designed layer by layer. It’s a great printing option if you want to build intricate models or products. Xometry offers many different SLA materials, many of which are transparent and useful for creating parts that you need to see through.

The photo shows some parts created through Xometry’s SLA service:

Various transparent tags made using SLA 3D printing

This chart points out the strengths and uses for an SLA printer. It also shows the materials it can manage and the types of things it can create.

| Materials | Strengths | Common Applications | Dimensional Accuracy |

|---|---|---|---|

Materials Polycarbonate-Like, ABS-Like, Polypropylene like | Strengths High resolution/detail, accurate, large print area | Common Applications Casting patterns, Prototypes, Concept models | Dimensional Accuracy +/- 0.002" - +/- 0.010" |

Get Instant Quoting Across 9 Different 3D Printing Processes

4. Selective Laser Sintering (SLS)

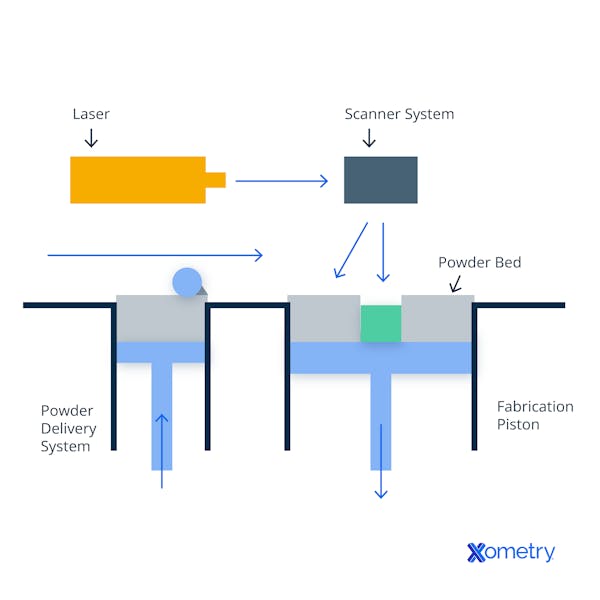

Selective laser sintering (SLS) swaps in those well-known plastic filaments for powdered plastic; typically nylon. This machine spreads a thin layer of this powder using a device called a recoater, then traces out the part’s cross-section with a laser. During the tracing, the heat from the laser melts the powder and it fuses together. The build chamber piston will then lower slightly, and another layer of powder will be spread across, and the process repeats until your product comes to life. This type of printing method does not require support structures as the un-sintered powder encases the parts throughout the medium, supporting them. For this reason, many parts can be built simultaneously in a single build which makes SLS printing superb for creating lots of parts at the same time, while retaining accuracy and quality.

The following diagram shows how an SLS 3D printer system works:

SLS 3D printing system.

This table lays out the materials you can send through this printer, what it makes, and its advantages.

| Materials | Strengths | Common Applications | Dimensional Accuracy |

|---|---|---|---|

Materials Nylon 11, Nylon 12, Filled Nylon (e.g. Glass-Filled) | Strengths No support structures needed, complex geometries, durable parts | Common Applications Concept models, end-use parts, medical devices | Dimensional Accuracy +/- 0.002" - 0.003" per inch |

5. Multi-Jet Fusion (MJF)

Multi-jet fusion printing has a lot of moving parts. On these machines, a layer of plastic powder is deposited that’s then warmed up by a heating head. An inkjet-style array hovers over top and precisely sprays fusing and detailing agents into the powder. The heating elements fuse it all together, and the process repeats. Like SLS printing, MJF parts do not require support structures due to the powder-based method, and therefore many parts can be printed simultaneously both horizontally and vertically in the build chamber. At Xometry, we offer both rigid and flexible materials through MJF and multiple finishing options, such as dyeing and chemical vapor smoothing to enhance the prints further.

The image below is an example of a part made using Xometry's MJF services, which in this case, has also been dyed black:

Nylon 12 part printed using MJF with a dyed black finish.

The following table shares the materials you can use with an MJF printer, what it can create, and its advantages.

| Materials | Strengths | Common Applications | Dimensional Accuracy |

|---|---|---|---|

Materials Nylon PA 12, Polypropylene, Glass Filled Nylon, TPU 88A | Strengths Highly Accurate, Fast, Low-cost | Common Applications Visually accurate prototypes, End-use parts | Dimensional Accuracy +/- 0.7mm |

SLS and MJF produce parts in well-known materials, primarily nylon but also PP and TPU. The parts are durable and behave typically of their base material. This allows engineers to test parts in a material that can also be transferred to other processes.Christian Tsu-RaunTeam Lead, Manual Quoting

6. Direct Metal Laser Sintering (DMLS)

When you’re in the market for a process that can 3D print directly in metal, look to direct metal laser sintering (DMLS) services. Similar to selective laser sintering, DMLS machines deposit a thin layer of metallic powder, then use their powerful lasers to trace out each part’s cross section layer by layer, fusing the metallic particles together to form parts. Unlike SLS, support structures are required as the heat and stress generated by sintering metal is much greater than with plastics. Due to their size, high cost, and the extensive post-processing steps required on parts after printing is completed, DMLS machines tend to only be found in industrial shops, such as those within Xometry’s network.

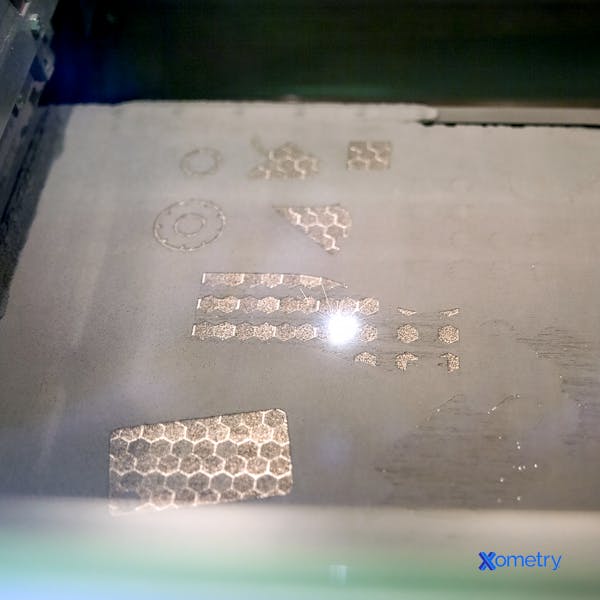

This picture shows a DMLS printer at Xometry in the midst of sintering parts from steel powder:

DMLS 3D printer sintering steel powder to form parts.

The following chart breaks down what you can make with DMLS printers, the materials you can use, and what kind of applications it’s good for.

| Materials | Strengths | Common Applications | Dimensional Accuracy |

|---|---|---|---|

Materials Stainless Steel, Aluminum, Nickel Alloys, Titanium | Strengths Highly detail, fully dense metal parts | Common Applications Aerospace & automotive components | Dimensional Accuracy +/- 0.005” for the first inch, plus +/- 0.002” for every inch thereafter. |

7. Electron Beam Melting (EBM)

If you dial up the difficulty level, you’ll come across printing methods such as electron beam melting (EBM). Like DMLS, these machines fall into the industrial category and require the related expertise. Its process is all in the name—it uses electron beams to fuse metal particles together. The machine puts down a layer of metal powder, then the beam does the tracing and melting. The beam can even be split to tackle multiple areas all at once.

In this chart, you’ll see the materials an EBM 3D printer uses, what it can build, and its strengths.

| Materials | Strengths | Common Applications | Dimensional Accuracy |

|---|---|---|---|

Materials Chromium, Titanium | Strengths Faster than DMLS | Common Applications Aerospace, medical, & petrochemical components | Dimensional Accuracy N/A |

8. Digital Light Process (DLP)

Some 3D printing options are similar to others, which is the case with digital light process (DLP) and SLA printers. The main difference is that a DLP machine will project an image using a UV light across the entire material vat at one time, instead of drawing the cross section one point at a time with a laser. Digital light processing has made access to photopolymer printing more accessible. It’s cheaper and faster than SLA, but it can still make high-quality parts.

This chart breaks down the materials, uses, and strengths of a DLP printer:

| Materials | Strengths | Common Applications | Dimensional Accuracy |

|---|---|---|---|

Materials Polycarbonate-Like, ABS-Like, Polypropylene like | Strengths Faster than SLA | Common Applications Jewelry Casting, Dental Splints, Miniature Figurines | Dimensional Accuracy 0.1 mm |

What are the 3D Printing Factors to Consider?

There are all sorts of 3D printers out there for every kind of need. You’ll want to think about the end product you’re trying to build, the materials you’d like it to be made of, and the budget and timescale you have. If you’re looking for a printer you can have at home for enjoyment and low-key production, hobbyist FDM or SLA printers may fit the bill. More advanced printers, like DMLS machines, are a better fit for industrial spaces and industries like aerospace, engineering, or medicine.

What is the Most Common Type of 3D Printing?

FDM printing is one of the most commonly used 3D printer types. This is due to its low cost and ease of use. When it comes to industrial plastic applications, however, MJF tends to be preferred. Manufacturing metal components tend to be done using DMLS.

What is the Best Type of 3D Printing for Beginners?

FDM 3D printing is the easiest 3D printing type for beginners. Not only is the process easy to understand but the raw materials are cheap and the equipment can also be found at very affordable prices. DLP printing is also a good starting point but tends to require a deeper understanding of 3D printing methods. DLP is also more expensive on average than FDM.

What is the Best Type of 3D Printing for Materials?

MJF printers have the widest range of materials available and can print multi-material and multi-color parts with relative ease. MJF printers can selectively color different parts of the print while also being able to place different material types into the same part.

What is the Best Type of 3D Printing for Medical Use?

Medical implants require advanced materials like stainless steel or titanium. As such, a powder bed 3D technology like DMLS is best suited to these applications.

What is the Best Type of 3D Printing for Construction?

3D printing in the construction industry is still in its infancy. However, large 3D printers successfully employ technology similar to that used in FDM printers to print concrete structures. This works by printing layers of concrete on top of each other to build a structure from the ground up.

What is the Best Type of 3D Printing for Education?

FDM printers are ideal for educational purposes. This is because their mechanics are easy to observe and understand. In addition, they are cheap to operate and the raw material is also cheap.

What is the Best Type of 3D Printing for Architecture?

Architecture firms use 3D printers to print scale models of their designs, and they commonly regard SLS as the most suitable type of 3D printing technology. This is due to the larger build volumes available and the ability of SLS to build parts with exceptional detail.

Frequently Asked Questions on Types of 3D Printing

How Much Does a 3D Printer Cost?

There are many different types of 3D printers on the market. As such, a 3D printer can cost as little as $150 for an entry-level FDM machine. The cost of advanced DMLS machines starts at around $250,000. 3D printers can be purchased directly from suppliers or on third-party websites like Amazon.

Is it Possible to Start a Business With a 3D Printer?

Yes, however, there is a low barrier to entry, so the market may well be saturated with like-minded individuals. However, using the latest 3D printing methods and supplying to a niche market is a good place to start.

Is 3D Printing a Profitable Business?

Yes, especially if advanced 3D printing services and materials are offered.

How Much Can You Earn in 3D Printing?

This depends entirely on the products and services offered. The value of printed goods can also vary from a few cents for plastic trinkets to thousands of dollars for advanced metal parts.

Summary

This article provided a look at 8 different 3D printing technologies, their applications, and their strengths.

Many of these processes and more are available at your fingertips through the Xometry Instant Quoting Engine®. All you need to do is upload your 3D CAD file, such as an STL, and configure your quote from the options to get instant pricing and lead times. Give it a try today and get your instant quote!

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.