Additive manufacturing refers to the process of creating a part by incrementally building it up via the addition of material. This material can be metal, ceramic, plastic, photopolymer, or even food! ISO/ASTM has categorized all the different types of additive manufacturing technologies into seven categories.

This article will describe how each of these types of additive manufacturing processes works, as well as their uses, advantages, and differences.

1. Binder Jetting

Binder Jetting is a powder bed-based additive manufacturing technology that creates parts by selectively depositing a binding agent onto a thin layer of powdered material. The process begins as the printer lays down a uniform layer of powder, typically plastic, metal, sand, or ceramic, on the build platform. A recoating blade is used to ensure that a precise layer of powder is distributed on the build platform. This is typically done by the recoater blade, transferring material from a powder storage bin next to the print area. The material in the storage bin is lifted, and the recoater blade sweeps the powder from the storage bin across the build platform at the required layer height. Next, an inkjet head moves over the powder and dispenses a binding agent over the powder in the shape of the part cross-section for the current layer. For full-color plastic parts, the binding agent also contains a colorant to create multiple-color parts.

The print bed then moves down by one layer height. The recoating blade distributes another layer of powder on top of the previous one, and the process continues. When binder jetting metals, the part must be sintered after printing to eliminate porosity and improve the mechanical strength. Alternatively, a low-melting-temperature metal powder like bronze can be mixed with the primary material. When the printed part is heated, the bronze will melt and fill the spaces between the primary metal alloy powder particles.

Table 1 below shows the typical materials, applications, and advantages of binder jetting:

| Materials | Applications | Advantages |

|---|---|---|

Materials

| Applications

| Advantages

|

2. Powder Bed Fusion (PBF)

Powder bed fusion (PBF) refers to a range of additive manufacturing technologies that fuse powders using a high-powered focused energy source. The energy source can be a laser (SLM or DMLS) or an electron beam (EBM). Both metal and plastic powders can be used with PBF. The process works by first placing a thin layer of powder (often pre-heated) onto the build platform. This is achieved with a recoater blade to ensure layer height consistency. A focused energy beam then melts the powder particles to form the current cross-sectional layer of the part. The build platform then moves down by one layer. Another layer of powder is added, and the process repeats.

Higher-power energy beams are needed for metals, and an inert atmosphere is required for DMLS and SLM printing. For EBM, the build volume must be kept under a vacuum. PBF machines can print quickly, particularly if multiple-beam printers are used. EMB uses only one beam, but the beam can be redirected extremely rapidly, thereby simulating multi-beam functionality.

Table 2 below shows the typical materials, applications, and advantages of powder bed fusion:

| Materials | Applications | Advantages |

|---|---|---|

Materials

| Applications Functional metal parts like turbine blades, rocket engine combustion chambers, and heat exchangers | Advantages

|

3. Directed Energy Deposition

Directed energy deposition (DED) is an additive material process used exclusively with metals. It is often used to repair existing metal parts. This repair capability is possible because DED can print in five axes of motion, unlike other printing processes, which are limited to three. A DED printer can maneuver around existing parts with complex geometries.

This type of additive manufacturing is not limited to repairs, but can also print brand-new parts. DED works by directing either a powder or a metal wire to the print nozzle. A laser or electron beam then melts the material and fuses it with the base material. Any weldable metal can be made or repaired with DED. As with welding processes, a shielding gas (laser beam) or a vacuum (electron beam) is required for DED printing. The gas will only cover the area that is actively being melted by the beam. Alternatively, the entire build volume can be saturated with an inert gas, which requires a sealed airtight build volume.

Table 3 below shows the typical materials, applications, and advantages of DED:

| Materials | Applications | Advantages |

|---|---|---|

Materials Metals (cobalt-chrome, titanium, Inconel, tantalum, niobium, stainless steels) | Applications

| Advantages

|

Material jetting utilizes a series of inkjet nozzles to deposit material onto a build platform, creating a part. This process requires the use of photopolymers as raw materials. It works by first depositing a layer of photopolymer onto the build platform. Next, a UV light source moves over the photopolymer to cure it. The build platform then moves down, and the process is repeated.

Since UV-light curing of the printed material is an integral part of this additive manufacturing process, only plastics, many of which are photopolymers, can be printed by material jetting. Support structures are required to print parts successfully by material jetting.

Table 4 below shows the typical materials, applications, and advantages of material jetting:

| Materials | Applications | Advantages |

|---|---|---|

Materials

| Applications

| Advantages

|

5. Sheet Lamination

Sheet lamination is a layered additive manufacturing process that builds parts by stacking and bonding sheets of material—rather than depositing or fusing powders or liquids. It can be used with a range of materials, including paper, polymer sheets, composites, and some metals. While the process typically yields low-resolution parts, it offers high production speed and low cost, making it advantageous for certain prototyping and industrial applications.

The process works by sequentially laying down thin sheets, each cut to match the cross-section of the part at that layer. These sheets are then bonded to the previous layer using various techniques depending on the material. In some systems, a laser or knife cuts the part geometry from the sheet before or after bonding. Excess material around the part can be removed during or after the build.

Metal sheets are commonly bonded using ultrasonic additive manufacturing (UAM), which applies ultrasonic vibrations under pressure to fuse the metal layers without melting. Plastic sheets are typically bonded using heat and pressure, either thermally or with adhesives. Composites (e.g., aramid fibers, fiberglass, or carbon fiber-reinforced layers) and paper are usually laminated using adhesives and compression. Sheet lamination is also used to create near-net-shape parts, which may be subsequently machined or post-processed using CNC or other subtractive techniques to achieve tighter tolerances and surface finishes.

Table 5 below shows the typical materials, applications, and advantages of sheet lamination:

| Materials | Applications | Advantages |

|---|---|---|

Materials

| Applications

| Advantages

|

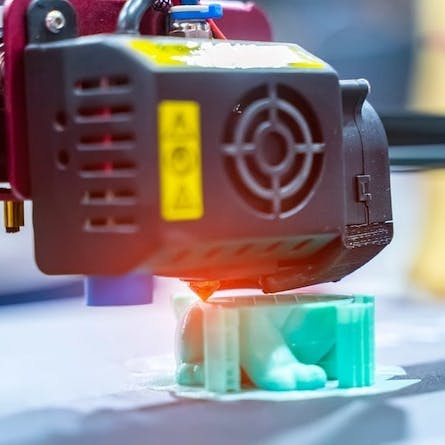

Material extrusion is one of the most well-known types of additive manufacturing, mainly due to its adoption by the consumer market. Material extrusion is often referred to as FDM (Fused Deposition Modeling), or FFF (Fused Filament Fabrication). The process works by directing a plastic filament from a supply spool, passing it through a heated chamber, and then out of a print nozzle. As the material exits the nozzle, it is deposited in the form of the current part cross-section on the build platform. Once a layer is complete, the print heads move up by one layer thickness. The process is repeated until the part is complete.

Thermoplastics and filled thermoplastics are the most typical raw materials used with this technology. However, metallic powder/polymer matrix materials can be used to create metal parts. They must be post-processed in a furnace to develop their final mechanical properties.

Table 6 below shows the typical materials, applications, and advantages of material extrusion:

| Materials | Applications | Advantages |

|---|---|---|

Materials

| Applications

| Advantages

|

7. VAT Photopolymerization

VAT photopolymerization is an additive manufacturing process that creates parts by selectively curing a liquid photopolymer resin using a light source. The two primary technologies under this category are:

- SLA (Stereolithography) – uses a UV laser to trace and solidify the cross-section of the part layer-by-layer.

- DLP (Digital Light Processing) – uses a digital projector to flash an entire layer at once, curing the resin simultaneously across the layer.

Both processes involve a vat of liquid photopolymer resin. The build platform starts just below the surface of the resin. In SLA, a laser beam scans across the resin surface to solidify the desired shape of the current layer. In DLP, a light projector flashes the entire layer image in a single exposure. Once a layer is cured, the build platform moves vertically (usually upward), allowing uncured resin to flow beneath the part, and the next layer is cured on top of the previous one. This process continues until the part is fully formed. Because the part emerges gradually from the vat, it appears as though the build platform is pulling the object out of the liquid resin.

Table 7 below shows the typical materials, applications, and advantages of VAT photopolymerization:

| Materials | Applications | Advantages |

|---|---|---|

Materials

| Applications

| Advantages

|

What Is Additive Manufacturing?

Additive manufacturing refers to the additive process of creating a part by building it up one layer at a time. This is in contrast to subtractive manufacturing, which starts with a solid block of material and removes any excess to create a part. CNC machining is an example of subtractive manufacturing.

Frequently Asked Questions About Types of Additive Manufacturing

What is the Most Frequently Used Type of Additive Manufacturing?

The most frequently used types of additive manufacturing are: material extrusion (FDM/ FFF), sheet lamination, VAT polymerization, and powder bed fusion (PBF). It is worth noting that the degree of adoption of each additive manufacturing technology varies depending on the industry it is used in. For example, the aerospace industry makes heavy use of DED and powder bed fusion.

What Organization Categorizes Additive Manufacturing Processes?

ASTM International and ISO are jointly responsible for the categorization of additive manufacturing processes. ASTM and ISO created the seven categories described in this article.

How Are Additive Manufacturing Processes Classified?

Additive manufacturing processes are classified under ISO/ASTM 52900, the international standard that defines key terms and categories in AM. It organizes technologies into seven process types, based on how layers are formed and materials are bonded. These categories include methods like material extrusion, vat photopolymerization, and powder bed fusion, among others. This classification helps ensure consistency across industries and applications.

Is 3D Printing an Example of Additive Manufacturing?

Yes, 3D printing is a form of additive manufacturing. In fact, it is the most widely known and commonly used example. The term "3D printing" is often used informally to refer to all additive manufacturing processes, which involve building objects layer by layer from digital models.

Summary

This article reviewed 7 different types of additive manufacturing processes and described how they work, their advantages, and their disadvantages. To learn more about the different additive manufacturing types and how each may be best suited to your specific application, contact a Xometry expert today.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.