Welcome to Xometry.com, your one-stop shop for all things 3D printing, CNC machining, sheet cutting, and injection molding! Whether you are looking for a way to kick-start your next prototyping project or ramp up to high-volume production, Xometry has you covered. We have access to dozens of high-performance materials that are the perfect match for your next 3D printing project. Today, we want to highlight an incredibly versatile material: Polyamide 12.

What is a Polyamide, And Why Are There 12 of Them?

Plastics have become a ubiquitous material found in products used throughout our modern life. What originally started as a way to replace pool balls made from elephant tusks (yes, that’s true). have become one of, if not the, most widely used materials for products around the world. One of the most useful kinds of plastics is nylon polymer. There are many different kinds of nylon polymers, and Polyamide 12 (PA 12), unsurprisingly, is a nylon polymer with 12 carbon atoms in it. This also explains its other commonly used name, nylon 12. Nylon polymers have many uses across a variety of industries.

So, what makes Polyamide 12 useful?

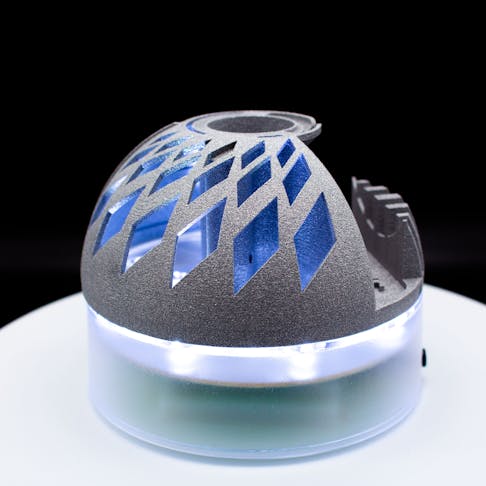

Polyamide 12 is an ideal material if you are looking to 3D print complex and detailed parts because of its narrow melt window compared to other thermoplastics. This material can remain in an unmelted state and very quickly transition through melted and unmelted states through selective heating. Processes like selective laser sintering can create parts out of PA 12 by heating the nylon powder up to near melting, and with a touch of a laser create a controlled melt, fusing layers of parts together to make complex shapes. The printed material is strong, and its ability to endure stress gives it the flexibility to bend before it cracks, making it versatile for a number of high-stress applications. Polyamide 12 also has great chemical resistance, and it absorbs very little moisture. Combined with the enhanced design freedom inherent in 3D printing, PA 12 can be used for consumer goods, medical, industrial, aerospace, and other high-performance applications.

What kind of end-uses does Polyamide 12 have?

PA-12 is useful when safety, durability, and reliability are of critical importance.

In the automotive industry, it's used all the time “In fuel lines, brake lines, pipelines — even the handles of certain power tools. PA 12 also is used in plastics for car seats and several consumer and sporting goods.” (Source). Polyamide 12 is also useful in the aerospace industry because it has great heat resistance. This is especially true for Polyamide 12 when it is combined with other additive and filler materials. Its chemical properties help make it resistant to abrasion, a useful characteristic when you are trying to design an aerospace part that won’t rip apart upon landing. In addition to PA 12, Xometry offers a wide range of temperature-resistant nylons with many different filler materials.

PA 12 is also very useful in the medical industry for use in medical equipment because it is biocompatible and nontoxic. Biocompatibility refers to a plastic's ability “to act and perform without impairing basic immunological functions of the body. The use of biocompatible plastics in the medical field is aimed to enhance healing functions without causing injurious, negative physiological, allergic or toxic reactions.” (Source)

PA 12 is incredibly useful plastic across many industries, but why should you use Xometry for Polyamide 12 end products?

Xometry Elevates Your Next 3D Printing Project

There are a few different ways Xometry can design your next project with PA 12. Xometry currently offers the ability to 3D print polyamide 12 across 3 manufacturing processes: HP Multi-Jet Fusion, Selective Laser Sintering, and Fused Deposition Molding. Each method has its own unique benefits, end-use applications, and relative costs.

And if you are looking for other high-performance plastics, you’re in luck! Xometry has recently added four high-performance 3D printed plastics to its on-demand manufacturing services: Nylon 11 EX (Rilsan® Invent Natural), Nylon 12 CF (PA 602-CF), Nylon 12 AF (PA 605-A), and Nylon 12 HST (PA 620-MF). These highly durable plastics complement the already-available Nylon 12 and Nylon 12 Glass-filled (GB) materials at Xometry. All 3D printed nylons boast great feature resolution and a detailed surface finish, with the natural white powders available for color dyeing.

With low costs, fast lead times, and the power of our global network behind us, we are equipped for your 3D printing orders, from rapid prototyping to high volume production. We encourage you to head over to the Xometry Instant Quoting Engine to get an instant quote for 3D printed parts in nylon 12. And if you want to learn more about PA 12 and our other high-performance materials, check out our webinar: A Deep Dive into SLS 3D Printing and Our New High-Performance Materials.