Tight Tolerance Parts? Xometry Delivers

Learn about Xometry's capability to meet tight tolerance requirements for your CNC, sheet metal, and sheet cut parts.

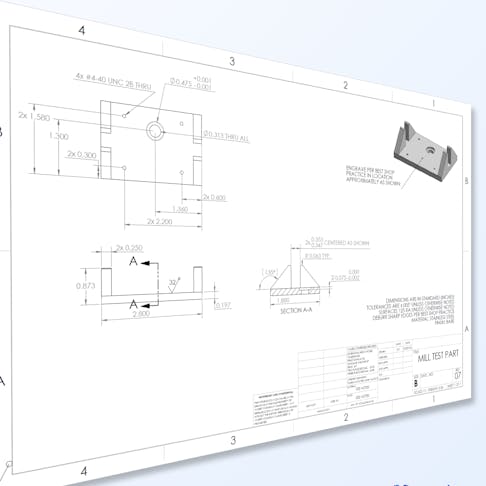

CNC Machining Tolerance Capabilities

Thanks to our platform, getting precisely milled or turned CNC parts is simple. We can automatically quote tolerances as tight as +/- 0.001" for various materials, including some plastics! We regularly machine parts with tolerance bands even narrower than this; however, features other than small and shallow reamed holes will require manual review.

Our CNC machining tolerance capabilities include:

- Auto-quotable tolerances down to +/- 0.001" for all metal materials

- Auto-quotable +/- 0.001" tolerances for PEEK, ULTEM, Delrin, Acetal, and PTFE plastics

- Sub +/- 0.001" tolerances achievable after manual review

- Default tolerances of +/- 0.005"

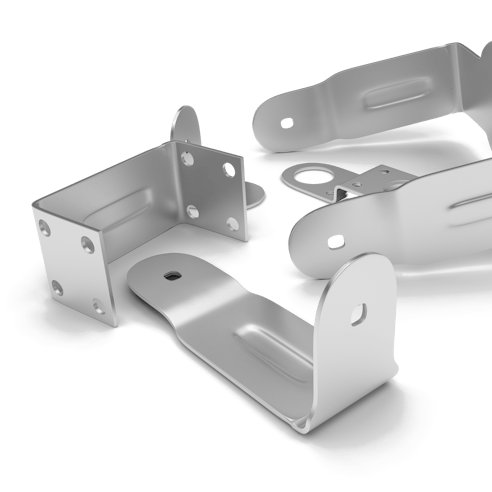

Sheet Metal Fabrication Tolerance Capabilities

With our sheet metal fabrication service, you can get high-precision bent sheet parts from tight-fitting brackets, instrument panels, perfectly aligned enclosures and chassis, and more! We can automatically quote sheet metal tolerances down to +/- 0.005", allowing you to quote and order your precision sheet parts without further delay. If your parts require inserts, that's not a problem. You can specify them in our system, and we will install them accordingly without the need to specify tight tolerances on insert features.

Our sheet metal bending tolerance capabilities include:

- Instant pricing and lead times on tolerances as tight as +/- 0.005"

- Sub +/- 0.005" tolerances after manual review

- Insert installation without the need to call for tight tolerances on corresponding features

- Default bending tolerances of +/- 0.020"

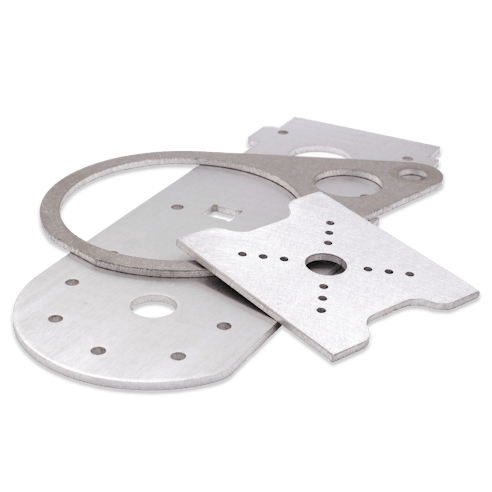

Laser and Sheet Cutting Tolerance Capabilities

Xometry's manufacturing network utilizes the latest laser and waterjet cutting machinery, enabling us to cut flat sheet parts with extreme accuracy. Our service makes manufacturing precision covers, plates, washers, shims, and various other parts for automotive, aerospace, medical, and other industries quick and easy. We provide instant pricing and lead times for metal or plastic sheet-cut parts with tolerances as tight as +/-0.005". Like our other offerings, we can support even tighter tolerances after further review.

More about our sheet cutting tolerance capabilities:

- Auto-quotable tolerances as tight as +/- 0.005" for metals and plastics

- Sub +/- 0.005" tolerances available with manual review

- Insert installation without the need to call for tight tolerances on corresponding features

- Default tolerances of +/- 0.010"

Tight Tolerances Made Simple

Configure Your Part

Click "Edit Configuration" to configure your parts.

Specify Tightest Tolerance

Check the box under "Tolerances" and select your part's tightest tolerance requirement.

Get Your Quote

Pricing and lead time will update automatically based on your selection.

Need Tight Tolerance Parts?