Case Study: Xometry Helps Autodesk Take Its Macro Keypad to the Next Level

For the second version of the macro keypad developed for Autodesk University's Factory Experience 2024, Autodesk partnered with Xometry to enhance the design, simplify the assembly process, and reduce the carbon footprint in manufacturing.

| Industries | Manufacturing Services Utilized | Project Brief | Solution |

|---|---|---|---|

Industries Consumer products | Manufacturing Services Utilized | Project Brief For its annual Autodesk University conference in 2024, Autodesk wanted to bring back its hands-on macro keypad assembly that it offered in 2023 with an improved version of the keypad. | Solution The revised design features improved fitment and tolerance stack management, simplified assembly processes, reduced carbon footprint in manufacturing, and optimized DFM (Design for Manufacturing) for each component. |

If you attend conferences as part of your work, your desk is probably sporting more than a few branded pens, cups, and other accessories. Everyone loves a good piece of conference swag, and the annual Autodesk University conference takes it to the next level by giving attendees an opportunity to build a useful keepsake with their own hands as part of the Factory Floor Experience. The hands-on session showcases some of the industrial processes powering the manufacturing industry and demonstrates how Autodesk Fusion® can help businesses build better products.

Autodesk has worked with Xometry since 2022 to produce the parts that go into the Factory Floor Experience projects. In 2022, Xometry produced the components for an electronic smart badge. The following year, the Factory Floor Experience project was a customizable macro keypad designed to be used with Autodesk apps. The keypad was so popular that Autodesk opted to showcase it in the Factory Floor Experience again in 2024, with a few important upgrades.

Build Your Next Project with Xometry and Autodesk Fusion

Autodesk Fusion is a cloud-based 3D CAD, CAM, CAE, and PCB platform that provides enterprise-grade capabilities, data services, and support to teams of all sizes. The Xometry CAD Add-in for Autodesk Fusion lets users instantly get price and lead time estimates and design-for-manufacturability (DFM) feedback from Xometry, allowing design engineers to see the direct impact of design changes on their part’s cost and manufacturability without leaving Fusion. This instant feedback enables creators to make better parts and increase speed to market.

If you're in Fusion, you can just grab a part and say, "Give me an estimate for this,’” Autodesk’s Fusion Community Manager, Jonathan Odom, said. And it's such a useful sanity check at the beginning of a project…The initial analysis is super helpful.”

Designing the Autodesk Keypad 2.0

When considering the upgrades he wanted to make to the keypad, Odom knew he wanted the second version to be sleeker and more ergonomic. “The original device honestly looks a little clunky,” he said.

Improved fitment and tolerance were also key to the redesign. When designing the original keypad, Odom said, “I got this idea in my head for some reason that everything needed to have as tight a tolerance as possible. I don't really know where that instinct came from, but obviously it's not the best idea, especially if you're talking about a consumer product. You need to keep dust out of cracks and stuff like that, but you don't need an aircraft-level tolerance between these parts. So the tolerances needed to be a little bit more loose. Simplifying the assembly kind of dovetails into that.”

The tight tolerances on the original keypad made it tricky for some people to put together since the attendees of the Factory Floor Experience “are not professional assembly line workers. They may have never really held a screwdriver,” Odom said.

In addition to making the keypad sleeker and easier to assemble, he wanted the new version to have optimized DFM and a reduced environmental impact.

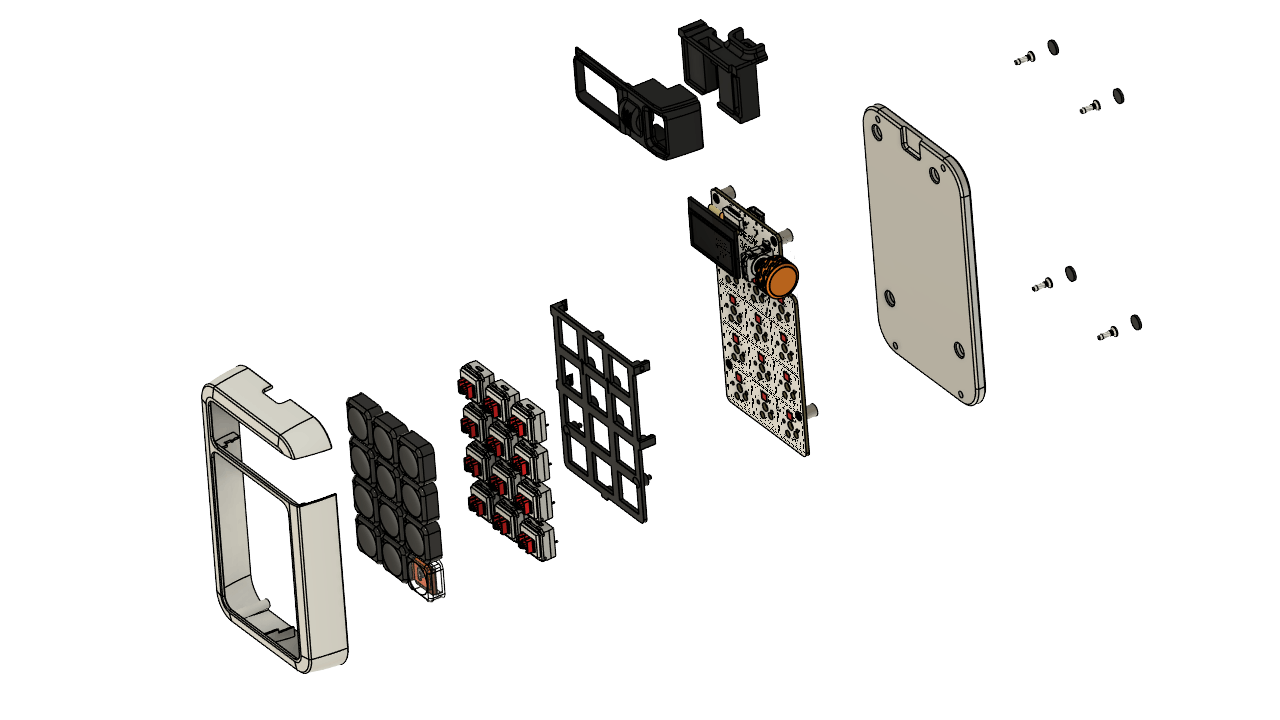

A Closer Look: Keypad Teardown

To achieve a more streamlined design that was easier to assemble, Odom and his team updated the injection-molded enclosure to add bosses for thread-forming screws that go through the base plate, as well as clips that hold onto the keyplate. This change to the design helps hold the assembly together before the screws are inserted, making it less challenging to put together while still being complex enough to be interesting. “There needs to be some effort put into putting it together, otherwise it's boring,” Odom said. “But if it's frustrating, obviously that's not an optimal outcome.”

The updated enclosure is also about a millimeter thinner, which reduced plastic use and the overall carbon footprint.

Both versions of the enclosure were made from polycarbonate with a frosted gray tint, and the newer version had a lighter, more transparent finish.

“One of the things I love about injection molding is there's just an endless array of finishes and colors and translucency and all kinds of stuff you can do,” Odom said.

Another benefit of injection molding is reusability. The keycaps in the original keypad design worked fine as-is, so Xometry was able to use the same tool to injection mold the keycaps for version 2.0. “You have one enclosure per assembly. But with keycaps…we have 11 or 12 per assembly. So you're making thousands of components for this. So it makes sense to keep this with molding,” said Greg Paulsen, Xometry’s director of applications engineering and marketing, who worked with Odom on the Factory Floor Experience project.

For the tray base, made from CNC-machined aluminum, Odom opted for a slightly different finish. “The first time we went with a clear anodized finish. We went with a satin clear anodized for the last one, which I really like. I see those tool marks on there. It brings the whole kind of manufacturing story into it,” he said.

One thing I can always count on with Xometry is that they're going to think about the little things…What do you want this thing to look like? What's the design intent? They're always looking for that when you're having a conversation with them.Jonathan OdomFusion Community Manager, Autodesk

Details Don’t Slip Through the Cracks with Xometry

The change in finish from clear anodized aluminum to satin clear anodized aluminum may seem like a small one, but this attention to detail is one of the reasons Odom continues to work with Xometry. “One thing I can always count on with Xometry is that they're going to think about the little things…What do you want this thing to look like? What's the design intent? They're always looking for that when you're having a conversation with them,” he said.

“I've worked with other suppliers before where they send me aluminum parts and they're just polished and they didn't even ask me what the finish quality was supposed to be. And it's a part that sees a lot of abuse. And then over time you've got something that's scratched and the customer's not happy about that, you're not happy about it,” Odom said. “But you can always count on Xometry to pay attention to those little things and give you what you need.”

To learn more about how Xometry helped Autodesk bring its revised keypad design to life, watch this webinar recording – featuring a full teardown of the keypad and a Q&A with Odom and Paulsen.

Want to give it a try for yourself? The Autodesk Keypad 2.0 is an open-source project – you can find the project files here.