Xometry Partner Network Profile: Cerven Solutions

Cerven Solutions has taken on almost 700 Xometry projects since the CNC machining and custom machining solutions provider joined the Xometry Partner Network in 2020. COO and co-founder James Cerven said partnering with Xometry has given his business a runway to grow and the ability to carve out a niche creating complex milled parts.

| Manufacturing Services Offered | Specialty | Xometry Jobs Completed to Date | Xometry Revenue to Date |

|---|---|---|---|

Manufacturing Services Offered CNC machining and custom machining solutions | Specialty Creating complex milled parts | Xometry Jobs Completed to Date 671 | Xometry Revenue to Date $1.5 million |

The pandemic lockdown in 2020 spurred many people to pick up a new hobby. While some were gardening or trying their hand at baking bread, mechanical engineering student James Cerven was learning his way around a CNC milling machine that he purchased with his brother, who is also a mechanical engineer. They didn’t know it at the time, but that Tormach PCNC 440 was the beginning of what would become a successful business.

Tinkering in the Garage Leads to Building a Business

What started as a pandemic diversion in their parents’ garage in Poughkeepsie, NY, quickly became a passion project for Cerven and his brother. They both “instantly loved” the CNC process and the boundless possibilities it offered for designing and creating, Cerven said. Before long, Cerven thought, “We need to make this a business because I want to do this for a long time. I really like doing this.”

Cerven credits Cerven Solutions’ first customers with giving the business an opportunity to become what it is today. “Our first customers were very generous people,” he said. “They were kind enough to give us some work. And definitely, looking back, I was like, ‘wow, these people were really nice to us,’ because we had no idea what we were doing at first … We gave them good parts, so that's what matters. There's a lot of good people in this industry.”

Joining the Xometry Network Opens Doors

In the early days of the business when Cerven was looking for ways to connect with potential customers, he came across a post in a machining group on Facebook that mentioned Xometry. After his initial conversation with a Xometry representative, Cerven realized that his business wasn’t quite ready to start taking on Xometry jobs, but he was intrigued by the business model that would let Cerven Solutions take on job opportunities that were a good fit without having to go through the process of quoting each job. After making a few updates, he was ready to join the Xometry’s Manufacturing Partner Network.

“We bought some extra tooling and more inspection equipment, and then we reached back out and passed the test part,” Cerven said.

Since joining the partner network, Xometry jobs have become a major part of Cerven Solutions’ business, sometimes accounting for as much as 80% of the company’s work in a given month.

“Since we're a job shop, nothing is ever guaranteed. We don't have any set-in-stone monthly contracts,” Cerven said. “With a lot of our direct customers, if you're not constantly quoting or winning [jobs], you can kind of be forgotten … But that isn't an issue with Xometry.”

In its five years as a Xometry partner, Cerven Solutions has completed more than 670 jobs for Xometry customers, bringing in more than $1.5 million.

Grow Your Shop With Xometry

Learn how becoming a Xometry supplier can help your business find profitable work, improve cash flow, and maximize shop efficiency. For more information, reach out to partneronboarding@xometry.com or schedule a Xometry Job Board demo.

Finding a Niche Allows for Focused Growth

In addition to bringing in a steady stream of jobs, working with Xometry has also allowed Cerven Solutions to serve customers in a variety of industries.

“If we had taken the more traditional path where you start your little shop and then you go door to door, we would have seen way less work, and less variety of work that way,” Cerven said. “It would have taken a really long time to [connect with] hundreds of different companies on our own, especially since I can't walk into a Fortune 500 company and just ask for work. I’ve tried, it doesn’t work!”

Having a wide variety of jobs to choose from helped Cerven Solutions discover what it does best. “Having access to such a wide variety of work has actually helped us a lot to be able to narrow down our niche, and know what we're really good at and where to invest,” Cerven said.

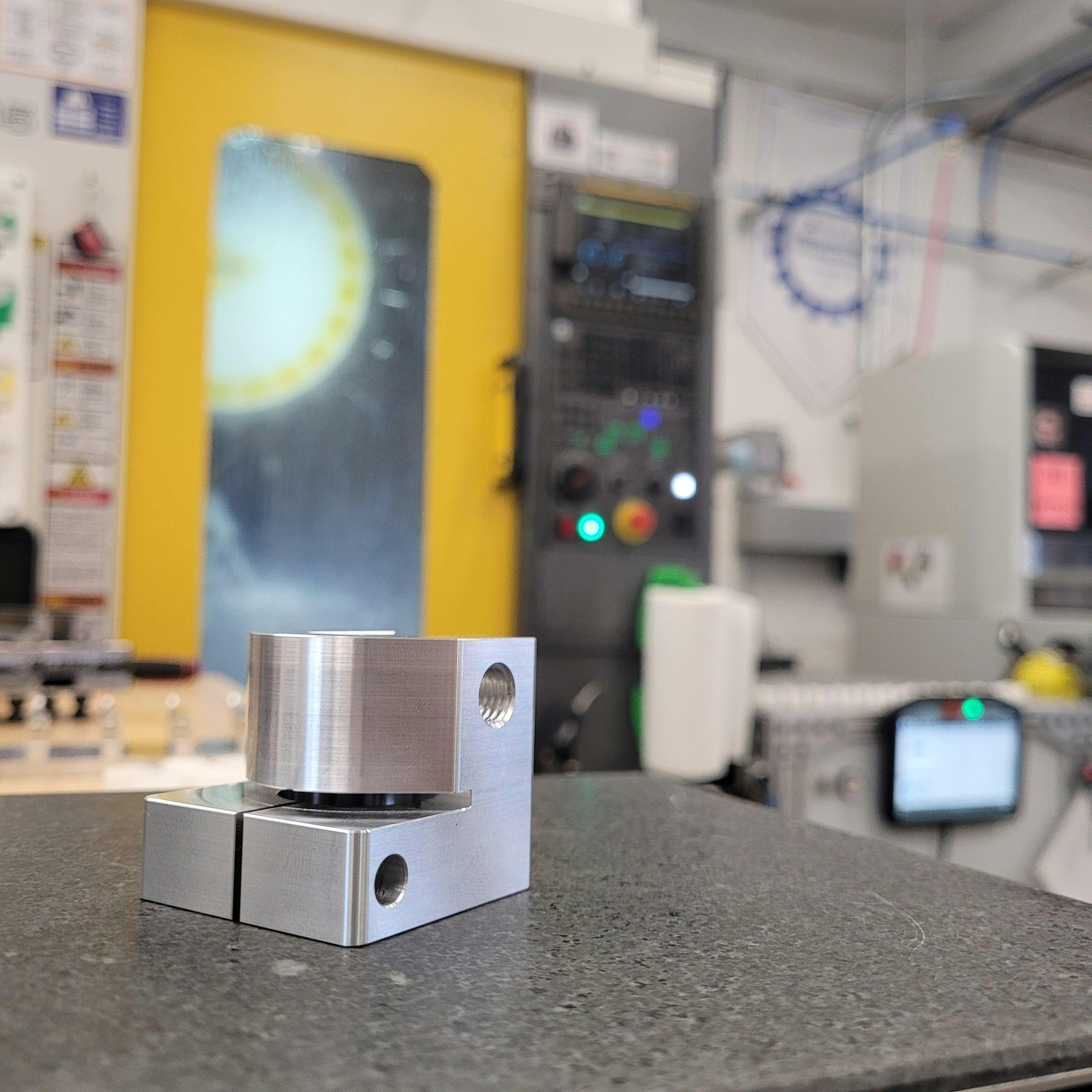

“Our niche is small, complex milled parts, usually under two inches,” he said. With this focus in mind, Cerven Solutions has been able to take more of those types of jobs and make investments to scale up their business. After quickly outgrowing the garage, Cerven moved the business into a 3,000 square foot workshop.

“We've got three machines and a fourth one on the way now, and we have a quality control employee right now. He's helping us with all the inspection and he's also going to help us get our AS9100 certification, which will open up a lot more work,” Cerven said. “You don't often see an inspection person as a dedicated employee for such a small shop. But we're able to be so flexible and competitive in what we do that we can afford to make these hires and really build the company well from the foundation.”