At a Glance

| Industries | Manufacturing Services Utilized | Project Brief | Solution |

|---|---|---|---|

Industries | Manufacturing Services Utilized | Project Brief The SawBlaze team needed to quickly source a variety of high-performance metal and plastic components to outlast the competition in season 7 of BattleBots. | Solution The SawBlaze team turned to Xometry for quickly sourced parts, giving them the edge they needed to stand up to fierce competition and well-supplied for every situation. |

Flamethrower fueled and primed? Check.

Saw blade running at 5000 RPM? Check.

Xometry Instant Quoting Engine® ready for rapid resupply of high-performance parts? Check.

SawBlaze is set to dominate season 7 of BattleBots! Ranked #4 in a pre-season poll, SawBlaze is the highest-ranked team of the 7 teams Xometry is sponsoring this season, and for good reason. Having participated in the BattleBot competition since 2016, team captain Jamison Go has been taking lessons from his robot fighting career to gradually improve his overhead buzzsaw battlebot into the multi-weapon-wielding warrior it is today.

“I was fascinated by the robots, the designs, the challenges, and the atmosphere of sports overlaid with robotics," said Jamison Go, avid roboteer and captain of Team SawBlaze. "The very first time I saw it, I was totally hooked. I started to dabble in my own mechanical creations. I began building more complicated robots, and there was one particular design I really gravitated toward.”

Go was heavily inspired by a modest middleweight robot affectionately named S.O.B. This scrappy little progenitor of the modern SawBlaze design also featured a dustpan capturing mechanism and overhead saw weapon system. It also weighed about 130 lbs less than most modern-day BattleBots.

"I wouldn't say it was the most effective or damaging robot, but it definitely had an interesting design that emphasized controlling the fight. And there wasn't really any other machine like it at the time. And while it didn't end up winning, that design stuck with me." said Go.

"I wanted to see if I could make it better," the SawBlaze captain reflected. "I carried that design inspiration with me throughout my entire career of fighting robots. From their 130-pound weight class bot design, I was able to build a 3lber, then a 30lber, and scaled my learnings to the modern 250-pound design."

BattleBots: Design Quickly, Repair Quickly, Restock Quickly

When you compare the original S.O.B bot to SawBlaze, you'll notice a design that has been gradually optimized over time. It has gone through a continuous process of minimizing some structures while maximizing others.

“The solid base and tall sidewalls at the front of the bot became a set of hardened steel forks designed to lift most opponent's wheels from the ground, essentially 'trapping' them. In our experience, optimization was key. We added more structure to parts of the bot that would experience more abuse and minimized areas that were seldom touched. The front armor section is nearly 1/3 of the weight allotment!” said Jamison Go.

One of SawBlaze’s greatest assets is its modular design. The bot features not just one but two overhead weapon systems, each specifically designed to help the bot succeed in a variety of situations. The hammer saw is their primary weapon system, combining damage, speed, and durability, leading to terrifying results. The circular diamond saw, on the other hand, is used exclusively for opponents with potentially entangling structures and thick, hardened steel armor. This adaptable modular design can make a tremendous difference when facing off against different opponents with their own strengths, weaknesses, and unique tactics.

This emphasis on modular design can be challenging for Team SawBlaze because, as with many engineering teams working in various industries, they have to quickly iterate designs while being spread across the United States. Once the bots go head-to-head, and parts start flying, teams need to repair and restock their parts quickly to keep them operational and ready to face their next challenger. While viewers at home may have to wait weeks between matches, the battling teams do not have that luxury. To endure the competition, they must make repairs on the fly as they prepare for their next battle, usually one day away. Thankfully, Team Sawblaze knows they can rely on Xometry when they need a rapid resupply.

“Getting quotes from Xometry is so fast and easy. It really helps when you need to find out how much a part is going to cost and how it is going to fit into your timeline,” said Go. “For us, that timeline is so critical. We need complete certainty around that delivery date because we have a very limited time window with BattleBots. We're doing our own internal scheduling, working on our assemblies, and planning with a team spread all across the US. Knowing that we can go super fast with Xometry is incredibly valuable for our team. And for really any engineering company, period.”

Jamison continued, “Normally, with a standard manufacturing service, you find yourself stuck in an email chain. Where you have to wait days for responses to get quotes back; those are valuable days that we can’t afford to lose in a competition like this,” said Go. “By comparison, Xometry’s system is extremely convenient.”

In addition to the near-instant quotes and rapid turnaround times, SawBlaze benefited from the bevy of options found in our easy-to-use proprietary platform.

“The Xometry Instant Quoting Engine® is super easy to use. We simply uploaded our STEP files and zipped through the drop-down menus,” said Go. “It has so many options that whether we needed to specify tapped hole or upload technical drawings, we knew we could find everything we needed there.”

To design their CAD files, Team SawBlaze used Xometry’s SOLIDWORKS add-in. This time-saving software allowed them to purchase custom-manufactured parts directly from their CAD workspace. The Xometry add-in analyzes the geometry of a CAD design and allows the user to select the material, process, and quantity to get an updated instant price and lead time.

Easy access to competitive custom manufacturing quotes within CAD platforms like SOLIDWORKS allows engineers like Jamison Go to get early manufacturing feedback and optimize designs for their price and timeline. Engineers from various fields — from automotive and aerospace to hobbyists and BattleBot teams — have used it to prototype and manufacture high-quality custom parts, allowing them to simplify their product development cycle.

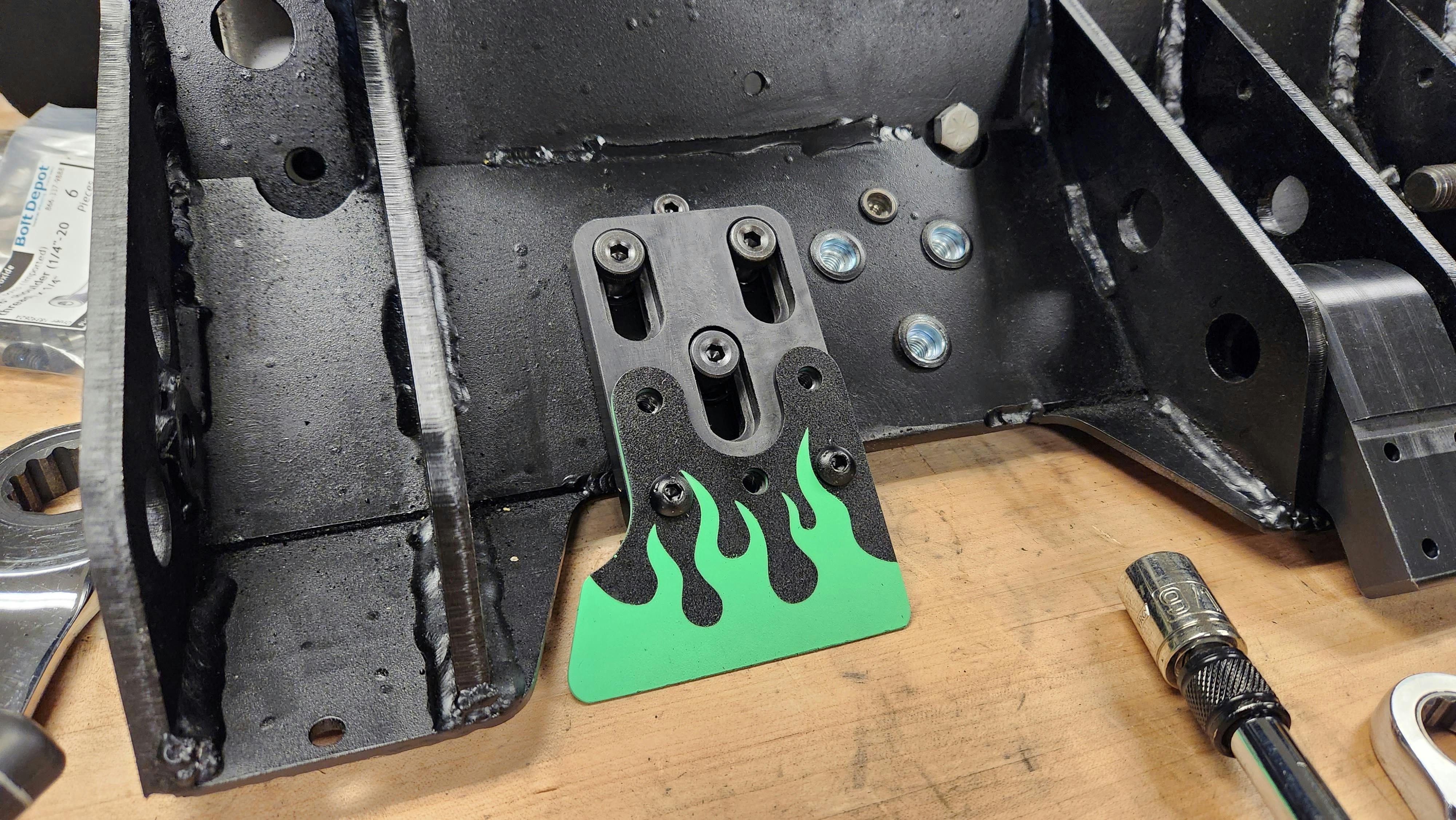

SawBlaze��’s signature weapon was created through Xometry, along with various metal components, which can be found in 3 major subsystems.

“The blades are made of AR steel, and the supporting titanium blade shafts. They're very nice. I almost feel bad using them!” said Go. He ordered these sheet-cut parts from Xometry using our Waterjet cutting service. "There are two different versions of the blade; the hammer saw is our general-purpose blade which stores energy in the rotation, and we slice into opponents in one fell swoop. This blade is made from thick, hardened steel for weight and durability. The diamond saw is a specialty blade for opponents with top armor we cannot penetrate with the hammer saw. We apply this blade gradually to abrade material away." said Go.

Compliant wedges, built by Xometry, allow the bot to get under its opponents without snagging obstacles.

“In addition to the blades, we also have this compliant wedge system, which has spring-loaded fingers that retract after hitting debris and imperfections on the floor. There are also sliders made of UHMW-PE plastic. They are low friction, high toughness,” Go said. “When the fingers hit a floor seam, they pull back a little bit, and then because they're spring-loaded, they snap back against the floor to maintain the wedge surface. These CNC-milled parts are defensive, and we use them against opponents that have plans to try and outreach us with our forks.”

Team SawBlaze is ready to compete in the 2023 BattleBots season because they can access a variety of manufacturing processes quickly and easily with Xometry. Xometry offers a full menu of manufacturing options to fabricate both plastic and metal parts and can combine parts from multiple processes together. Our engineering team is always ready to help solve potential engineering challenges encountered along the way. We can optimize your design for your next project, whether into fully realized commercial products or fire-breathing mechanical monstrosities.

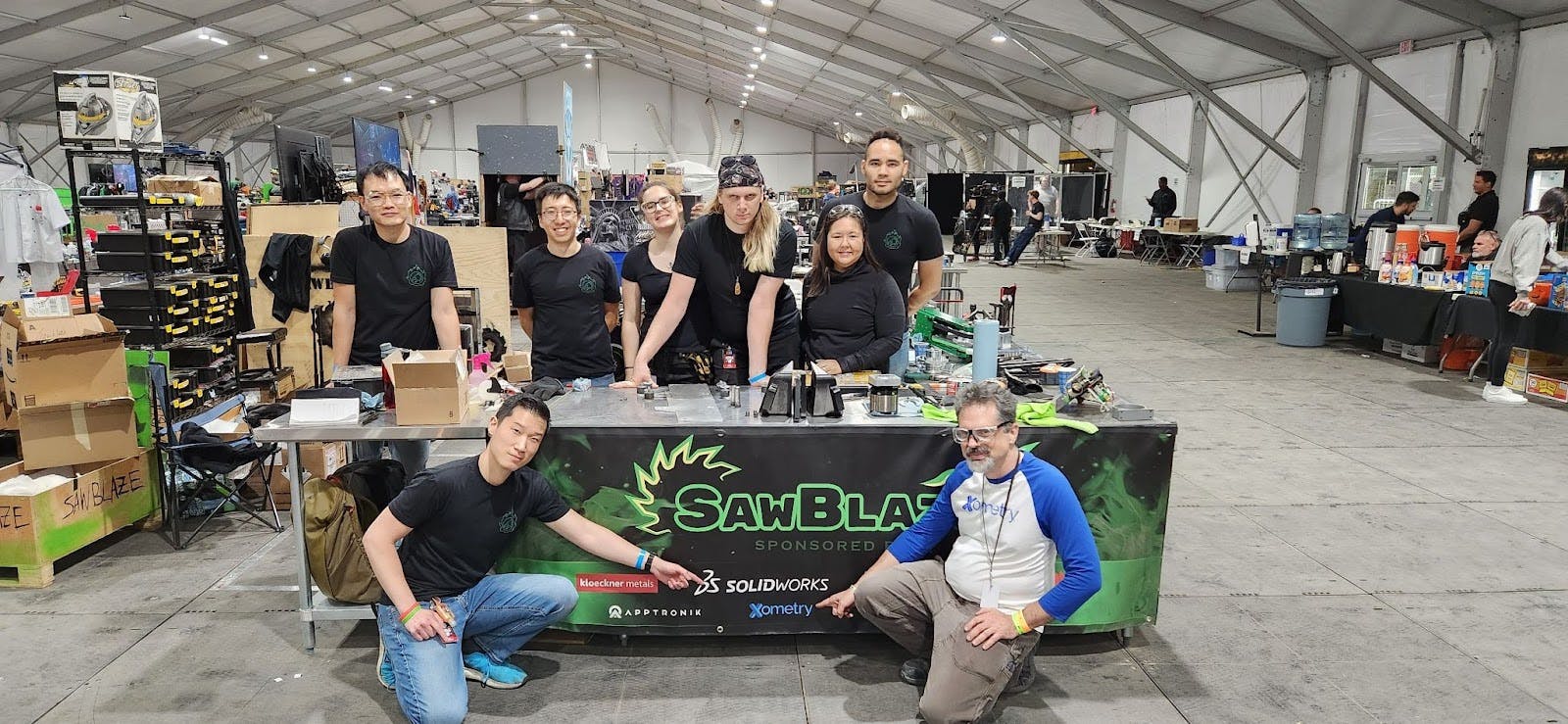

The Battlebots pit with team SawBlaze and Xometry's Simon Arthur delivering parts.

Go may have exceptionally designed parts and years of experience, but that can only get it so far without the right team behind it.

Team SawBlaze’s captain praised his team for their competitive efforts: “I can't talk enough about how much I love my team this season. In my mind, they’re the real heroes. I talk about all the hard work that they did. I can’t wait to see how we perform this year.”

Xometry is trusted by teams worldwide to produce high-performance parts, from iconic BattleBot weaponry to air purification systems used by NASA on the International Space Station. If your team needs a helpful manufacturing resource to build their next big idea, consider referring them to Xometry.

Do you and your team need to quickly source high-quality laser and sheet-cut parts? Visit the Xometry Instant Quoting Engine® for instant pricing, lead times, and DFM feedback.

*Xometry is not a sponsor of, or affiliated with, BattleBots, Whalerock Industries, or Discovery Network.