Design Guide: Direct Metal Laser Sintering (DMLS) 3D Printing

Direct metal laser sintering (DMLS) 3D printing is a revolutionary technology that is changing the way manufacturers create prototypes and end-use parts. Check out our free guide to learn how to make the most of this amazing additive manufacturing technology.

Download the Guide

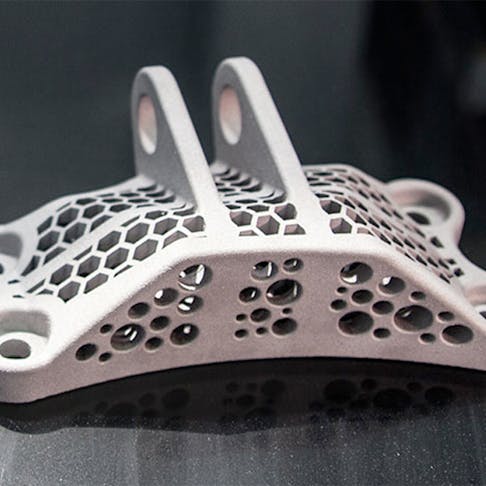

Direct metal laser sintering (DMLS) is a metal 3D printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques. DMLS is often used as a substitution for aluminum or steel metal casting.

Direct metal laser sintering (DMLS) 3D printing is a revolutionary technology that is changing the way manufacturers create prototypes and end-use parts. Check out our free guide to learn how to make the most of this amazing additive manufacturing technology.

About Xometry

Xometry's direct metal laser sintering metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote (See our Manufacturing Standards for more details). Find out the cost of the parts you need using Direct Metal Laser Sintering or compare the costs of DMLS vs. SLS. Get an instant quote today.