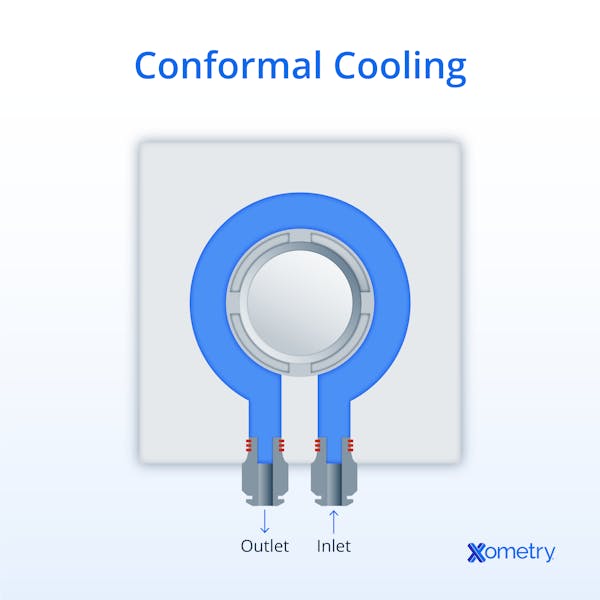

Conformal cooling is a way to cool plastic parts, typically during the injection molding process. This method of cooling was developed to remove heat evenly from complex parts. By using metal 3D printing to manufacture the cooling channels, they can be custom designed and manufactured to closely conform to the shapes of even the most complex part geometries.

In conformal cooling, channels are positioned near the corners and recessed features of the part. This design is nearly impossible to achieve with conventional methods, like milling or drilling. Evenly distributed curved channels are wrapped strategically around the part to cool the sections that are hard to reach and usually difficult to cool. The channels can also be designed to easily accommodate features like ejector pins or attachment screws while maintaining a constant distance from the mold surface. Overall, conformal cooling allows for faster cooling times, better cooling efficiencies, improved part quality, and cost reductions.

This article will further describe conformal cooling, discussing how it works, its importance, and its limitations.

What is Conformal Cooling?

Conformal cooling is a technique that incorporates custom cooling channels into the tools used in plastic injection molding or blow molding processes. The cooling channels can be specifically designed to match part geometries for more effective and uniform cooling. Pairing conformal cooling with injection molding can reduce cycle times by 10 to 40%, and sometimes even up to 70%, compared to conventional cooling methods.

How Does Conformal Cooling Work?

Conformal cooling works by circulating a coolant through channels designed into injection molds for plastic parts. The coolant can be either liquid or gas, depending on the application’s requirements. Liquid conformal cooling is used with plastic injection molding materials that cannot withstand high temperatures or that require fast cycle times. Gas conformal cooling, on the other hand, is used for less demanding applications where the material being molded has higher temperature resistance and/or longer cycle times are used (i.e., polycarbonate). While water is used as a coolant for most applications, oil is used when the mold should be chilled at temperatures close to or above the boiling point of water. If the mold needs to be cooled at low temperatures (below the freezing temperature of water), a mixture of ethylene glycol and water is typically used. For gas coolants, air can be used, but this is not as efficient as the other coolant options (e.g., water).

Why Should You Use Conformal Cooling?

Conformal cooling is favored across various molding processes because it enhances cooling speed, improves overall part quality, and increases process efficiency. By providing uniform cooling tailored to the part’s unique geometry, it effectively addresses issues like warpage and uneven temperature distribution. For more information, see our guide on Plastic Injection Molding.

Why is Conformal Cooling Important for Injection Molding?

In injection molding, conformal cooling is critical because it significantly reduces cycle times and enhances temperature control. Its custom-designed channels deliver uniform cooling that minimizes defects such as sink marks, weld lines, and differential shrinkage, leading to improved part consistency and reduced warpage. These enhancements boost production rates and lower overall manufacturing costs, making conformal cooling especially valuable for complex or thin-walled parts.

Which Injection Molding Part Should Be Cooled Conformally?

Conformal cooling is ideal for plastic parts with complex geometries (parts with thin walls and intricate features) that are difficult to cool evenly. Uniform cooling minimizes the chance of part defects in these complex designs. Conformal cooling is also ideal for parts that have: difficult-to-reach spots, curves, bends, or features like ejector pins or attachment screws. For more information, see our guide on the Plastic Injection Machine.

What Are the Benefits of Conformal Cooling?

There are some distinct benefits associated with conformal cooling, including:

- Reduced Cycle Times: The cooling phase is often the longest part of the injection molding cycle. Conformal cooling reduces the cooling time and, therefore, reduces the total cycle time.

- Higher Quality Parts: Because conformal cooling causes more uniform mold cooling, it produces fewer molding defects and less part warpage. This uniform mold cooling results in higher-quality parts.

- Less Raw Material: Conformal cooling can reduce the raw material needed compared to conventional methods, as more efficient mold designs are possible, though the actual savings depend on the specific design and manufacturing process.

What Are the Limitations of Conformal Cooling?

The following limitations are associated with conformal cooling:

- Time-Consuming Design Phase: Conformal cooling mold designs need to be carefully optimized to generate the best and most efficient cooling. Preparing 3D printed mold tooling is more time-consuming than preparing a conventional mold.

- Limited Tool Size: For conformal cooling molds created using 3D printing technology, the part size will be limited to the size of the 3D printing bed.

- Cost of the Mold: Conformal cooling molds are more expensive than conventional cooling molds. The cost is only justified when parts are produced in large production volumes.

- Small and Long Channels: It can be difficult to remove the support powder when long and small channels are used to cool the part.

- Scaling: For intricate channel designs, scaling can occur. This means that the flow is decreased and the integrity of the wall of the cooling channel can be compromised, potentially leading to leaks.

One of the current downsides to conformal cooling components is that they are manufactured in highly specific machines. The replacement components may take longer to build which could lead to extended down time if a spare component is not available. As the process gains in popularity and additive mold building become more mainstream the industry will see the lead time to manufacture conformal cooling components quicker.Scott BensonBusiness Unit Manager

How Are Conformal Cooling Channels Created?

It is possible to manufacture a conformally cooled mold in several ways: direct metal laser sintering (DMLS - a 3D printing technology), vacuum brazing, and liquid interface diffusion. Of these, only DMLS is currently a practical production method. Vacuum brazing and liquid interface diffusion are considered to be too expensive over conventional cooling methods.

Today, the best way to make conformal cooling channels is with metal 3D printing technology – more specifically, direct metal laser sintering (DMLS), also known as powder bed fusion. With this additive manufacturing process, custom conformal cooling molds can be cost-competitive with conventional designs for large production volumes only. 3D printing allows for complex internal structures that would be impossible to produce with conventional methods. This capability allows the inserts of mold tools to be customized with cooling channels that will fit the shape of the molded part, leading to more uniform part cooling.

Frequently Asked Questions About Conformal Cooling

What is the Temperature After Conformal Cooling Has Been Performed?

Conformal cooling does not change the target part temperature after cooling. The change in temperature is based on the material and the design being molded. What conformal cooling does is change the rate at which the part cools to the desired temperature.

How Long Has Conformal Cooling Been Around?

Conformal cooling using additive manufacturing started in 1990 after the invention of the first metal powder 3D printer. Back then, CO2 lasers and metal powder, coated with a polymer binder, were used to manufacture the molds. Technology has since advanced and now uses 3D printing systems with precise lasers and metal powder to create the mold in an oxygen-free environment.

What is the Difference Between Conformal and Conventional Cooling?

Conventional cooling systems rely on straight, drilled channels positioned near the mold surface, which can leave complex or internal areas less effectively cooled. In contrast, conformal cooling channels are custom-designed to follow the precise contours of the part and are produced using advanced manufacturing techniques such as metal 3D printing. This approach allows for the integration of curved channels that can be adapted to intricate geometries - capabilities that conventional methods cannot achieve.

Conformal cooling is a great way to improve the quality of your plastic parts. It's also an energy-efficient and cost-effective process that can save you time and money in production. However, its cost-effectiveness is most pronounced in high-volume production runs where the benefits of faster cycle times outweigh the higher initial mold manufacturing costs.

Summary

This article presented conformal cooling, explained what it is, and discussed when to best use conformal cooling in manufacturing. To learn more about conformal cooling, contact an Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including injection molding and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request afree, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.