Rapid injection molding (RIM) is an injection molding process used to manufacture low-volume batches of plastic parts with significantly shorter lead times than conventional production injection molding. In general, the equipment used for RIM is the same as that used for normal production injection molding, except that RIM molds are designed for quick turnaround rather than long series production durability.

The reduction in concept-to-production lead time primarily comes from using softer mold materials, such as aluminum, which are less expensive and easier to machine than the hardened tool steels used in standard injection molds. The molds lack the durability for long production runs, but are sufficient for smaller batches.

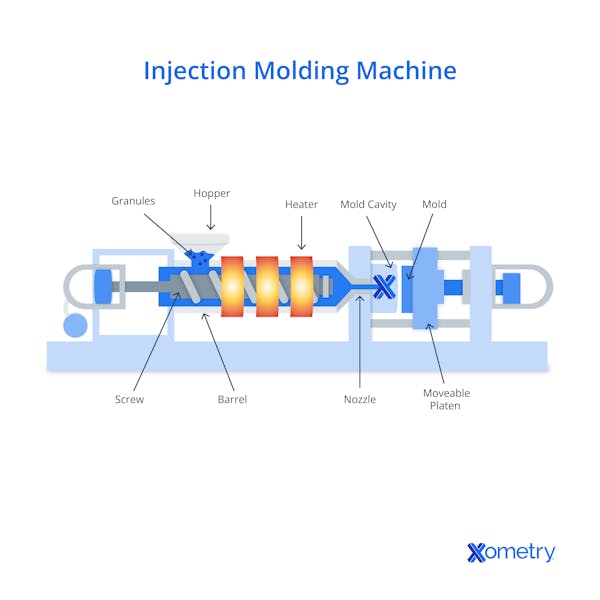

This article will describe the rapid injection molding process, explain how it works, discuss the equipment used, and provide some tips on selecting the optimal part material. A typical injection molding machine diagram is shown in Figure 1.

What is Rapid Injection Molding?

Rapid injection molding uses normal injection molding equipment and techniques, but does so at a much shorter lead time and lower cost. This short lead time is desirable for custom prototypes and manufacturing limited-volume production runs to iron out any potential design issues before committing to full production-scale injection molding. This speed mainly comes from using low-cost, easy-to-machine molds that can be manufactured in just a few weeks. Rapid injection molding must not be confused with reaction injection molding, which involves mixing liquid thermosetting polymers (such as polyurethane) and injecting them into a mold where they chemically cure.

For more information, see our guide on Plastic Injection Molding.

Where is Rapid Injection Molding Being Used?

Rapid injection molding is primarily used for prototyping, research, and developmental applications that do not require hundreds of thousands or even millions of parts. RIM is best suited for production runs that typically range from a few dozen parts to about 10,000, depending on part complexity and mold material. This allows engineers to test their designs with limited capital investment, rather than immediately committing to the very expensive and long-lead-time tooling needed for high-volume series production.

Production injection molds cost so much partly because they must be made from highly wear-resistant materials to ensure that they can withstand the rigors of long-term production use. For that reason, RIM is often used to bridge the gap between initial design and full-scale production and is a cost-effective way to test new products, materials, and design tools. RIM can also be used to manage sharp increases in product demand volume.

How Does Rapid Injection Molding Work?

Rapid Injection Molding (RIM) parts must be designed with DFM (Design for Manufacturing) principles for injection molding in mind. A RIM mold is specifically created to be inexpensive and quick to manufacture, using standard, off-the-shelf materials. Aluminum molds are typically used as they are easier and faster to machine, but are not able to handle high-volume production.

Once the specialized RIM mold is manufactured, its two halves (core and cavity) can be mounted onto the stationary and moving plates of a normal injection molding machine setup, because the rest of the molding process is the same for both RIM and standard injection molding. The halves of the mold are brought together and held in place with hydraulic rams.

To actually make parts using the RIM process, the raw material (typically thermoplastics) is fed into a screw housed in a cylinder called a barrel. A combination of heat provided by external heaters mounted on the barrel and heat produced by shear (or frictional) forces between the plastic pellets and the action of the screw in the barrel, melts the plastic pellets. Once enough plastic has been melted, the screw pushes this plastic into the mold through a nozzle, and a one-way valve on the screw stops pressure from receding back into the screw. High-pressure plastic then fills the mold, and the hydraulic rams ensure that the plastic does not ooze out at the split line between the mold halves. After a few seconds, the plastic solidifies and the mold opens. The part is ejected using ejector pins, the screw retracts, and the process repeats. It is worth noting that rapid injection molding does not produce individual parts any faster than standard injection molding.

Where is the Equipment for Rapid Injection Molding Typically Made?

The equipment for rapid injection molding is typically made by injection molding machine manufacturers. Manufacturers are based worldwide, with many major suppliers in Asia (especially China and Japan), Europe, and the United States. Note that the only difference in terms of equipment between rapid injection molding and standard injection molding is the mold. These molds are made by injection molding tool makers.

What Are the Components of a RIM Press?

The components used in a rapid injection molding (RIM) press are described in detail below. The main components are the same parts that are used in a standard injection molding press.

1. Hopper

The hopper is where the thermoplastic resin pellets are placed for dispensing. The hopper is normally fed from bulk bags or a silo, depending on the required production volume and part size. This hopper provides a continuous supply of material to the screw. In some cases, it dries or preheats the resin to improve melt consistency in the screw and barrel. This reduces the per-part production cycle time. The hopper may also have level sensors to warn operators that they need to top up the material in the hopper.

2. Screw

The reciprocating screw has multiple functions. First, it meters and transports the correct amount of material from the hopper into the mold. While transporting the raw material, it rotates, forcing the pellets into an ever-decreasing volume, primarily due to the screw channel depth decreasing along its length. This creates enough heat to melt the pellets via the shear force created by the plastic pellets shearing against the screw and the barrel. Some screws also mix the material to create a more homogeneous melt, and in some cases, to ensure evenly mixed additives. Once enough material has been melted, the screw rams forward and a one-way valve at its tip prevents backflow, forcing the melt into the mold. The screw then retracts, and the process is repeated.

3. Barrel

The barrel houses the screw and is designed to guide the raw material into the mold. The barrel typically has heating elements wrapped around it to assist in melting the pellets. The screw forces the plastic pellets against the barrel and causes an increase in friction, which melts the plastic. The injection nozzle is located at the end of the barrel.

4. Heaters

The barrel has a number of electrical heaters wrapped around it to aid in heating up the plastic pellets. These heating elements initiate melting, but the majority of heat comes from shear generated by the screw. The screw action forces pellets against the barrel wall, generating shear heat that helps melt the plastic.

5. Materials

Rapid injection molding primarily uses thermoplastics, which may be commodity grades (such as polypropylene) or engineering grades (such as nylon and polycarbonate).

6. Nozzle

The nozzle directs the injected plastic into the mold. It may have a diameter of anywhere from 2.5 to 10 mm, depending on the capacity of the injection molding machine. The nozzle is screwed directly onto the barrel. Nozzles may have filters to prevent unwanted particles from entering the mold. There are two different filter styles: screen pack and gap filters. Screen pack filters are not popular, as they impede the flow through the nozzle, creating pressure loss. In contrast, gap filters provide a larger filter area and do not impede the flow as much. Nozzles can also have a mixing function that creates a homogeneous melt and helps in dispersing additives like colorants more evenly throughout the melt.

7. Mold

The mold is typically made from two parts: the core and the cavity. The different parts of the mold are each mounted to a plate called a platen. One mold half is held stationary while the other half is pressed against it with a hydraulic ram. This ram applies enough pressure to ensure that the plastic does not exit the mold at the parting line. Molds often have cooling channels machined into them to allow for a heat transfer fluid to remove heat from the mold. These cooling channels help the part solidify quicker and reduce the overall cycle time. Once the part solidifies, the molds open, and a set of ejector pins pushes the part from the mold. The mold closes, and the cycle repeats.

RIM molds are often made from aluminum or softer steels and are designed to last from a few hundred to several thousand parts, depending on part complexity and material abrasiveness. Another method used to reduce costs and increase production speed in RIM is to use master unit dies (MUD), which allow for modular molds that enable quick implementation of design changes without having to remanufacture an entire mold from scratch.

8. Part

The part is the end result of the injection molding process. Injection molded parts must be designed with injection molding design for manufacturing principles in mind in order to achieve high-quality parts. These rules determine the optimal wall thickness, where to add reinforcing ribs, hole sizes, etc.

What is the Wall Thickness of Rapid Injection Molded Parts?

The wall thickness of a rapid injection molded part is typically 1-3 mm, though the optimal value depends on the selected material. However, this thickness also depends on the material being used, as different materials have different ranges for optimal wall thickness. There is no difference between the wall thicknesses common with normal injection molding and what is possible with RIM.

How to Choose the Best Materials for Rapid Injection Molding

Choosing the best material for RIM depends on the desired end use of the product. RIM is used for prototype, pilot, and short-run volumes, bridging the gap between design and full-scale production. Thus, the materials used must be the same as those intended for full-scale production. One key advantage of RIM is that multiple materials can be tested to determine which is optimal. Some key considerations when deciding on the best material are cost, mechanical strength, UV resistance, electrical properties, and thermal resistance. These properties can be enhanced with additives like glass or carbon fibers. However, such fibers are abrasive and significantly reduce mold life, especially for aluminum molds.

Frequently Asked Questions About Rapid Injection Molding

What Materials Are Used for Rapid Injection Molding?

Rapid injection molding uses commodity thermoplastics such as polypropylene and polyethylene, as well as engineering-grade materials like ABS, nylon, and polycarbonate.

What Are the Benefits of Using Rapid Injection Molding?

The key benefits of using rapid injection molding are reduced lead time, the ability to validate designs before full production, and the flexibility to test multiple materials. It also supports low-volume production runs for bridge tooling or on-demand manufacturing.

Is Rapid Injection Molding Quick?

Yes. Lead time from design to sample parts is much shorter than that of full-scale production molds.

Summary

This article presented rapid injection molding, explained what it is, and discussed different parts of an RIM press. To learn more about rapid injection molding, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including injection molding and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.