CNC machining, or computer numerical control machining, is a manufacturing process that uses computer-controlled machines to cut metal or other materials into intricate shapes. It offers many benefits that make it valuable across numerous industries.

CNC machining allows machinists to modify or reproduce existing parts based on digital models, but in most cases, the process still requires a new setup or reprogramming rather than physically reshaping a finished part. When creating a new part, machinists use CAD (computer-aided design) software to generate detailed models that can be converted into machining instructions. The software itself doesn’t minimize waste, but it enables accurate tool-path planning that can help reduce scrap during production. This method reduces waste and saves money through automation and computer precision rather than manual operation. Additional valuable differences become apparent depending on the application. In this article, we'll look at some of the top CNC machining benefits.

1. CNC Machining Generates Minimal to No Waste

CNC machining minimizes material waste through its precision and accuracy. When programs are properly verified, CNC machines make very few cutting errors, but tool wear, programming mistakes, or fixturing issues can still produce scrap. The machine can handle precise cuts and angles without generating much waste.

2. CNC Machining Is More Accurate and Has No Defects

One of the major CNC machining benefits is accuracy. Because CNC machines follow precise computer instructions, their results are identical each time and match the digital model closely. This is a huge advantage when it comes to creating parts with tight tolerances. This capability greatly reduces human error, though programming and setup mistakes can still occur.

3. CNC Machining Offers More Rapid and Effective Production

Another key CNC machining benefit is its high production speed and efficiency. CNC machines produce parts much faster than traditional methods. Many modern CNC systems can be integrated with automatic loading and unloading equipment, such as robotic arms or pallet changers, to reduce manual handling. Naturally, this capability leads to significant cost savings and increased productivity. Additionally, this type of automation ensures parts are more consistent.

4. CNC Machining Makes Assembly Faster

Products whose components are created under computer numerical control are simpler to assemble. Because CNC machining is precise and consistent, companion parts fit together exactly as they do in the computer model. Since the process is quicker than manual machining, less time is spent waiting for parts to be completed. Unless there is a problem in the computer model, all parts should fit together perfectly. This capability can save a lot of time and money in the assembly process, as there is no need for extensive fitting or adjustment.

5. CNC Machining Separates Machines From People And Reduces the Risk That Would Otherwise Arise

CNC machining reduces safety risks on the shop floor. Automation eliminates many hazards associated with manual machining. In addition, CNC machines are typically enclosed, which further reduces the risk of injury.

6. CNC Machining Uses Little Energy

CNC machining can use less electricity than older processes, reducing overall energy consumption. There is no verified EPA data showing a specific energy-use ratio. Energy consumption depends on machine type, material, and process parameters. CNC systems can be more efficient because of optimized tool paths and reduced idle time. CNC machines not only work quickly but also draw less power per minute than most other manufacturing methods.

7. CNC Machining Can Reduce Production Costs

CNC machining is an economical and precise process for manufacturing parts and products. CNC machining can minimize material waste through optimized tool paths and consistent accuracy, although raw stock usage is usually the same as in conventional machining. Focusing production around CNC technology can significantly reduce errors, production time, and overall costs.

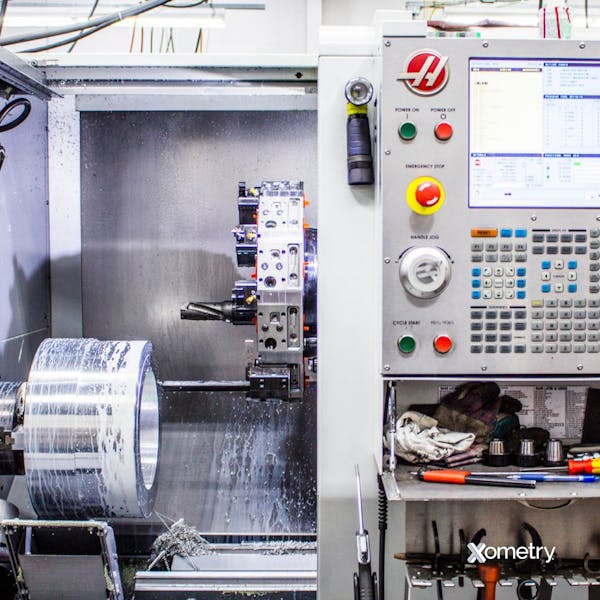

Figure 1 is an example of a CNC machine:

What Is CNC Machining?

CNC machining is a subtractive manufacturing process used to create parts by removing material from a workpiece or workpiece stock. Preprogrammed software and codes are fed into the machine to control the movement of its equipment. CNC machining includes various machine types, such as milling machines, lathes, grinders, and electrical discharge or plasma cutting machines, depending on the process and material. An example of a CNC machine is shown in Figure 1.

The first commercially developed CNC systems were primarily applied to metal-cutting machines, such as milling and drilling units, in the 1950s. CNC milling machines perform complex operations mainly on metals and plastics, and sometimes on wood or composites; glass is rarely machined mechanically because it tends to fracture. These machines have many different features and capabilities that allow them to create intricate shapes, cut out designs, and even engrave words onto products. Although CNC machines were costly in the 1970s and 1980s, advances in electronics and control systems have made desktop and benchtop CNC units far more affordable and accessible to hobbyists and professionals today.

What Is the Importance of CNC Machining?

CNC machining is critical in today’s industrial environment for its ability to produce accurate, repeatable, and affordable products. The method enables items that would be impossible or prohibitively expensive to fabricate using other manufacturing techniques. For example, CNC machining is widely used to produce telecommunications components such as heat sinks, amplifier housings, and structural parts for antennas or towers that require precise tolerances. The method enables the precise manufacture of intricate mechanical parts that meet defined technical specifications, dimensions, and geometry.

How to Choose a Good CNC Machine

There are many things to consider when choosing a CNC machine. Here are some tips to consider:

- Project Goal: Consider the project's goal before anything else. A CNC router is generally best for wood, plastics, and soft materials. For metals, a CNC mill or lathe is usually preferred, while a CNC plasma cutter is suited mainly for cutting sheet metal rather than machining it.

- Cost: Bear the price in mind. Cost includes labor and maintenance expenses in addition to the machine’s purchase price.

- Machine Weight: Take into account the machine's weight. Cast iron or polymer-composite machine frames provide high stiffness and vibration damping for heavy-duty operations. If not, alternative lighter-weight equipment will usually work.

- Power: The power rating of the equipment is yet another crucial factor. This will influence your cost analysis and must also fall within the capabilities of your facility’s electrical system.

Where Does CNC Machining Offer the Best Benefits?

CNC offers the best benefits when the following are among your top goals:

- More accurate parts than you can achieve with traditional methods

- Products with very consistent dimensions

- Production of a large number of parts

- Creation of complex designs

- Reducing manufacturing costs

What I value most about CNC machining is its predictability: when accuracy and automation align, efficiency follows naturally.

What Industries Gain the Most from CNC Machining?

The following industries gain the most from CNC machining:

- Medical

- Electronics

- Tooling and Moldmaking

- Transportation

- Woodwork

- Construction

- Agriculture

- Aerospace

- Manufacturing

- Automotive

- Firearms

- Metalwork

How Is CNC Machining Used?

CNC is a manufacturing method used to automate and precisely control many types of machine tools, including grinders, lathes, mills, routers, and EDM machines. These systems produce a wide range of components, including molds, fixtures, and precision-machined metal or plastic parts.

Summary

Xometry provides a wide range of manufacturing capabilities including CNC machining, 3D printing, injection molding, laser cutting, and sheet metal fabrication. Get your instant quote today.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.