Hole drill electrical discharge machining (EDM) is a manufacturing service that just seems to keep on growing in popularity. It’s a great way of making cooling channels in turbine blades, starter holes for wire EDM cutting, and even removing broken taps and drills from machinery that’s being manufactured or reworked. This article will explain the hole drill EDM process and how it’s used.

What Is Hole Drill Electrical Discharge Machining?

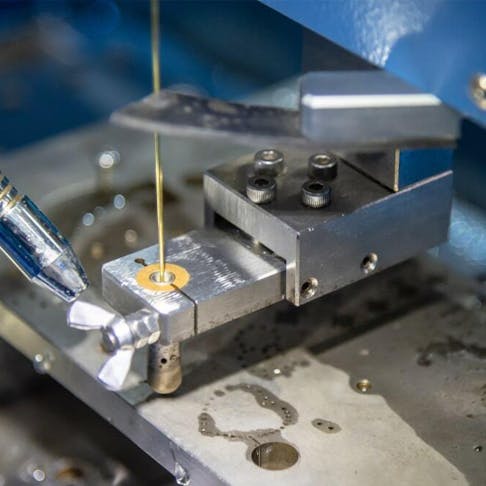

As the name suggests, hole drill EDM is a type of electrical discharge machining that’s intended to drill small, yet deep, holes. These holes can have diameters as small as 0.065 mm and be as deep as 1 m—basically 250 times the hole’s diameter. That’s almost impossible to beat using other methods. It uses an electrode, usually made of tungsten, graphite, brass, or copper, which is essentially a hollow tube that allows dielectric fluid to flow through it. The electrode and the workpiece are both connected to a power source—the electrode is usually negatively charged, and the workpiece is positively charged.

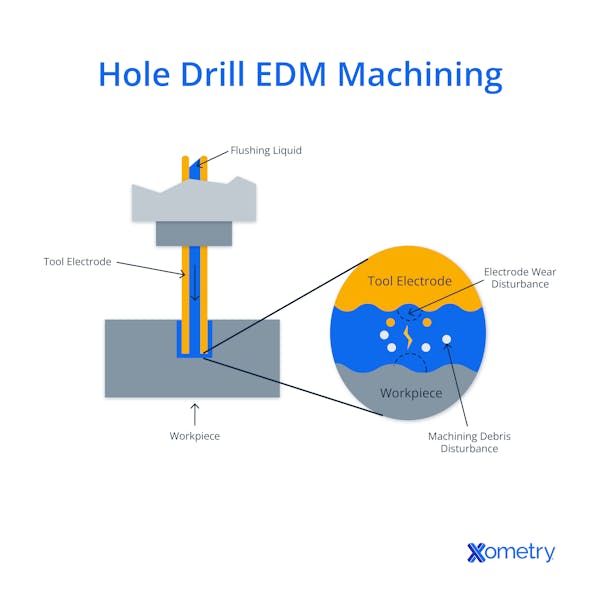

As the electrode nears the workpiece, sparks will start to appear, and these can reach temperatures between 8,000°C and 12,000°C, and rates between 500 and 30,000 sparks per second, although only one will hit the workpiece at a time. The fluid, which stabilizes the electrode, and clears away debris and eroded material, is pumped through the electrode to prevent short circuits and withstand the electrical flow until the voltage reaches a point high enough to generate a spark. Each spark vaporizes and erodes a tiny part of the workpiece; so as they continue, the hole gets deeper. The image below shows how the process works.

Hole Drill EDM Machining

This machining process is good for drilling holes through curved surfaces and with hard-to-machine metals like hardened steel, stainless steel, or tungsten carbide. It can be used to drill “through holes” or “blind holes,” although sinker EDM machines are better for the latter because hole drill EDM machines can’t always make flat-bottomed holes.

How Does Hole Drill EDM Work?

EDM drilling works by using a small electrode to drill a hole in a workpiece. The electrode is typically made from tungsten, graphite, brass, or copper. The electrode is actually a hollow tube, designed to allow dielectric fluid to flow through it. The tubular electrode may have multiple passages in it to smooth and facilitate fluid flow. The electrode is guided to the workpiece. When it comes close enough, sparks are generated between the electrode and the workpiece. These sparks can create localized temperatures of between 8,000 and 12,000 °C. Sparks can be generated at a rate of 500 to 30,000 per second. However, only one spark strikes the work at a time. High-pressure dielectric fluid is typically pumped through the center of the hollow electrode to act as a resistor to prevent shorting until a high enough voltage is supplied. When a high enough voltage is supplied, the dielectric fluid ionizes, and a spark is created. The high-pressure fluid also increases the overall stiffness of the electrode and carries particles eroded from the workpiece out of the hole during drilling.

Who Pioneered the Use of Electrical Discharge Machining?

In 1770, Joseph Priestley, an English physicist, was the first to document the effect of spark erosion. A husband and wife team of Soviet scientists named Dr. B. R. and Dr. N.I. Lazarenko took this research further in 1943 and invented the first electrical discharge machining process. The first practical EDM machine was designed to remove broken taps. This machine was developed by a company called Charmilles in 1952.

What Is Another Name for Hole Drill Electrical Discharge Machining?

There are many different names for hole drill EDM. Some of the most commonly used are: fast hole EDM, micro hole EDM, hole popper EDM, deep hole drilling EDM, and small hole EDM.

What Is Hole Drill EDM Used For?

Hole drill EDM machining is mostly used for drilling small, precise holes in hard materials. It can be used to drill through holes or blind holes. Blind holes, however, are better suited to sinker EDM machines as hole drill EDM machines cannot always create a flat-bottomed hole. Some of the important applications for hole drill EDM are creating cooling channels in turbine blades, making starter holes for wire EDM cutting, and removing broken taps and drills from machinery being manufactured or reworked.

How Accurate Is Hole Drill EDM?

A hole drill EDM machine is extremely accurate. It can hold tolerances as small as +0.0025 mm on hole diameter and +0.025 mm on hole straightness for a hole depth of 150 mm and diameter of 1 mm. This level of accuracy for small, deep holes is impossible to achieve with traditional drills because drill bits that are small in diameter will deflect, bend and break during drilling.

Who Manufactures Hole Drill EDM Machines?

A number of companies manufacture hole drill EDM machines. Some of the most well-regarded brands include Makino, Mitsubishi, TEK4, and Sodick.

What Are the Advantages of Hole Drill EDM?

Hole drill EDM machining has some advantages over other drilling methods, as listed below:

- Hole drill EDM can drill holes with diameters as small as 0.065 mm.

- Hole drill EDM can drill holes with a depth of up to 1 m. This measurement is impossible to achieve with any other manufacturing technology.

- Hole drill EDM can drill through very hard materials, including: stainless steel, tool steel, and tungsten carbide. Any material can be drilled provided it is conductive.

- A hole drill EDM electrode can drill holes through curved surfaces. Attempting to drill holes through curved surfaces with a mechanical drilling machine will result in the drill bit "walking" along the curved surface.

What Are the Disadvantages of Hole Drill EDM?

Hole drill EDM is an extremely capable process, but it has some disadvantages that must be taken into account. The most important downsides are listed below:

- Hole drill EDM is a slow process, although the speeds are continuously being improved. In general, drilling a single hole can take several minutes. For that reason, it is not suitable for high-volume production applications.

- Hole drill EDM is a relatively expensive process because of the time it takes to produce parts and the high energy consumption.

- Hole drill EDM is limited to drilling conductive materials. It cannot be used on plastics or composites.

What Is the Best Hole Drill EDM Machine?

There are many different hole drill machines on the market. Choosing the correct one for your needs depends heavily on the application and the available budget. Some of the best hole drill EDM machines are listed below:

- TEK4 6g FHD GXL: This range of hole drill EDM machines has a number of useful features including a multi-access build table to allow for the drilling of angled holes. A built-in CMM (coordinate measuring machine) probe ensures repeatable accuracy and an ATC (automatic tool changer) allows for the automatic selection of different electrodes.

- Makino EDAF: The EDAF range of EDM machines is capable of drilling small diameter holes as well as performing sinker EDM processes. This feature makes it an excellent machine for the smaller job shop that requires maximum flexibility.

- Mitsubishi VH10: This machine can produce holes as small as 0.065 mm in diameter in hard materials like tungsten carbide.

Frequently Asked Questions on Hole Drill EDM

How accurate is hole drill EDM?

Hole drill EDM is perhaps the most accurate process, especially for making small holes. Using a hole that’s 150 mm deep and 1 mm wide as an example, EDM can hold tolerances as small as +0.0025 mm on the hole diameter and +0.025 mm on its straightness. It all boils down to the fact that this process doesn’t use drill bits, and bits that small would very likely bend, deflect, or break during the drilling process.

Is Stainless Steel Suitable for Hole Drill EDM?

Stainless steel is a conductive material. As such, it can be processed using hole drill EDM.

Is Hole Drill EDM Machining Available at Xometry?

Yes, Xometry offers hole drill EDM through our extensive network of certified partners. Reach out to a Xometry representative today for guidance on the best ways to manufacture the small, deep holes on your part.

How Xometry Can Help

With all of its benefits, EDM is being used more and more in almost every industry. This is a process we’re very familiar with here at Xometry, and we offer many related services, like sinker EDM and wire EDM. You can get a free, no-obligation quote quickly by uploading your design to our Instant Quoting page or contacting one of our representatives if you have any EDM-related queries. In case you didn’t know, Xometry also offers a large array of other manufacturing services, like 3D printing, and CNC machining, which you can just as easily get a quote for.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.