When you consider how tools, molds, and other components are made, the all-encompassing term “tooling” will likely come up. This type of process has everything to do with how specific instruments and tools are made. They will then serve as important test-run prototypes for businesses or go on to be used and sold commercially, making manufacturing, engineering, design, and construction processes easier. More importantly, there are two techniques to consider when you’re trying to decide on the next best move — hard tooling and soft tooling.

Up ahead is a rundown of everything you should know about the differences and applications for both hard and soft tooling and the instances in which each is best. We’ll also explore the offerings Xometry has, whether you’re interested in injection molding production or lower-volume urethane casting services.

What is Soft Tooling?

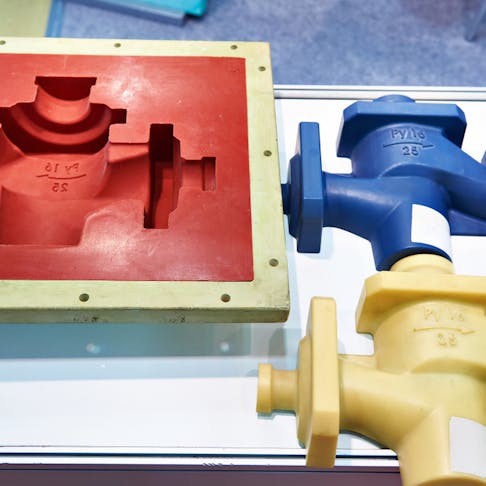

This type of tooling gives designers, engineers, and manufacturers a chance to test out tools and parts before they’re mass-produced or completely finalized. Because this process uses materials that aren’t as tough and easier to modify, the soft tooling molds that result are essentially another helpful way of prototyping. You’ll find that there are processes specific to both types of tooling, such as urethane casting, which creates silicone or plastic molds that can then be tweaked and adjusted then copied in a different material for the final tool it’s destined to shape and create.

This methodology means you can create a smaller number of units and try them out before you commit to a larger investment and quantity of goods in more expensive materials. Not only this, but soft tooling is also helpful for bringing parts and products to market sooner, even better if the long-term goal is to transition into hard tooling. Certain materials are better than others when it comes to soft tooling, and you’ll usually see silicone, carbon fiber composites, and fiberglass — basically easy-to-modify materials.

Advantages and Disadvantages

Here are the benefits of using soft tooling when creating different parts:

- Fast turnaround: Because of the materials used to make soft-tooled parts, they’re easier to make and therefore have speedier turnaround times.

- Cost-effective: You’ll normally rely on soft tooling for prototyping and low production quantities, and because of this and the kinds of materials used in soft tooling, it tends to be much cheaper.

- Complex designs: Thanks to the flexibility of soft tooling materials and the fact some soft tools can be made via additive manufacturing (e.g., 3D printing), you’ll notice that it’s much easier to create intricate geometries, detailed shapes, and other complex designs that are highly accurate. However, keep in mind that designs that work in a soft tool may not translate well into a hard tool, so it’s always good to think about if you’ll need to make that transition at some point while working on your designs.

On the reverse side, here are some of the disadvantages of soft tooling:

- Limited volume: Soft tooling isn’t built for large production runs and high numbers of goods, so it’s better to rely on hard tooling for those instances.

- Shorter tool life: Soft tooling molds aren’t as durable as the tougher and more rigid materials used in hard tooling. This means they will wear out quickly and need to be replaced more often.

- Deformities and wear are expected: Over time, soft tooling parts can start to warp, deform, and wear down, which isn’t ideal for maintaining dimensional accuracy. They are best when used right away.

- Materials are weaker in some respects: Many of the materials used in soft tooling wouldn’t be able to hold up to certain chemicals, temperatures, stresses, or uses, and so they’re better left for testing and mock-ups.

Higher cost per unit: While it might be cheaper to do a smaller production run, the shorter lifespan of components made with soft tooling means you’ll have to create and replace these parts more frequently.

What is Hard Tooling?

While soft tooling is ideal for perfecting a mold or prototype, hard tooling is the process you’ll need when it comes time to finalize a product and produce larger batches. With hard tooling molds, you can stamp, machine, cast, weld, and injection mold without worrying about the durability or integrity of the mold during the process. Due to the materials used and the more substantial parts and molds being made, hard tooling is more expensive upfront. It usually has longer lead times, too, because of the additional machining these tools receive (like heat treatments and post-processing) — this isn’t always ideal if quick turnarounds are essential.

However, the parts are often of better quality, and you have the potential as a manufacturer to make larger quantities with hard tooling. Even with higher costs upfront, the long-term investment will wind up being cheaper than soft tooling when producing high quantities. Hard tooling materials, unsurprisingly, tend to be harder and more rigid than soft tooling, so you’ll find that steel, nickel, and aluminum alloys are the most popular choices.

Advantages and Disadvantages

Here are several benefits to using hard tooling, especially in comparison to soft tooling:

- Stronger: Thanks to being made of strong metal alloys, hard tools have better heat resistance and durability, which lead to a longer tool life and allow them to work with tougher materials.

- Precision and repeatability: Once you have the models down pat and your designs are set in stone, there is no better way to replicate components with accuracy and precision than through hard tooling. This type of tooling can easily be used thousands of times before wearing out.

- Higher production capacity: Hard tooling is better for larger production runs, and these molds can contain several cavities within one mold, making them more efficient and cost-effective for production.

- Long-term cost savings: Hard-tooled molds last longer than their soft-tooled counterparts, and therefore, you won’t have to replace them as much and they can produce a higher number of parts at a lower cost as a result.

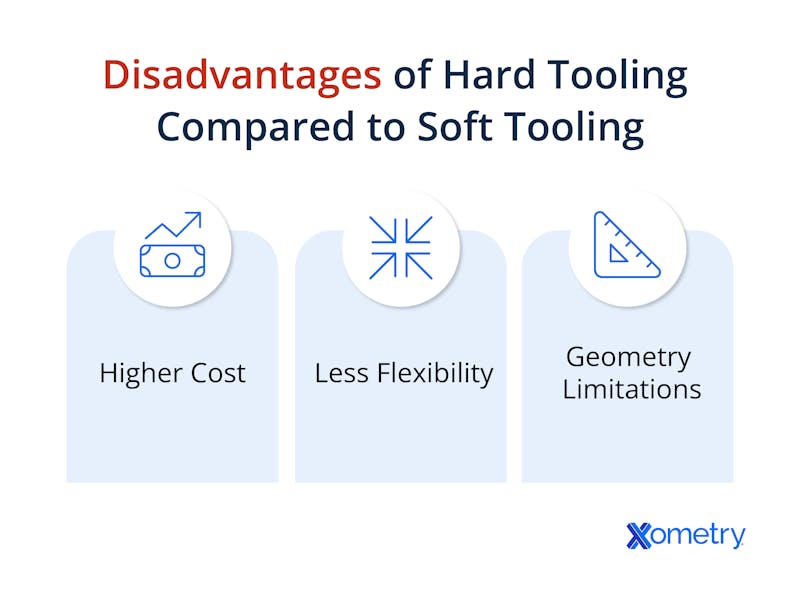

Here are the downfalls of leaning on hard tooling:

- More costs up front: It costs a lot more to produce hard tooling molds, and it takes more time than soft tooling. This means there will be more initial investment in both terms of time and money before you’ll see final parts delivered.

- Less flexibility: Made from harder materials, like steel alloys, you don’t get the same flexibility in changing parts made with hard tooling. Hard tools are manufactured with the final design and molding material in mind, which means you may not be able to use the same tool for different materials and incorporating design changes can be challenging or warrant an entirely new tool.

Design limitations: Unlike soft tooling, which can be made from a variety of processes like casting or 3D printing, hard tools don’t have that luxury. Hard tools are typically made with conventional manufacturing techniques like CNC machining, so your designs will be limited to the design restrictions of those processes. Xometry will help you navigate any design concerns during the ordering process for hard-tooled orders such as injection molding.

How Xometry Can Help

Whether you are developing your initial prototypes, just entering the market, or looking for tens of thousands of parts, Xometry has the prototyping and tooling services you need along the way.

Xometry offers instant quoting for soft tooling processes like urethane and silicone casting for those needing production-quality parts at low volumes. For those ready for full-scale production, we offer hard tooling processes like injection molding and metal stamping.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.