Thread milling and tapping are two methods of making threads in metal; those spiral grooves inside or outside of a hole that screws are meant to fit into. They’re both popular milling processes in the manufacturing industry, but they are very different. Let’s take a look at these two threading processes, the differences between them, their pros and cons, and when each should be used.

What is Thread Milling?

Thread milling is a manufacturing technique used to create threads. Instead of using a standard tool (like a tap), thread milling uses a specialized cutting tool designed for just this purpose called a thread mill. This mill is guided by a CNC machine for precise control, and its key feature is that, to make a thread, it moves the tool sideways in a circular pattern and carves it out in just one full turn.

This means that it can make threads with very precise spacing (thread pitch) — perfect if you need various sizes and completely customized threads to fit specific needs, without having to buy pricey rigid taps. For example, a 16-pitch thread mill can cut any 16-pitch thread, and you can easily switch to other sizes or pitches with the same tool, just by changing the machine’s program.

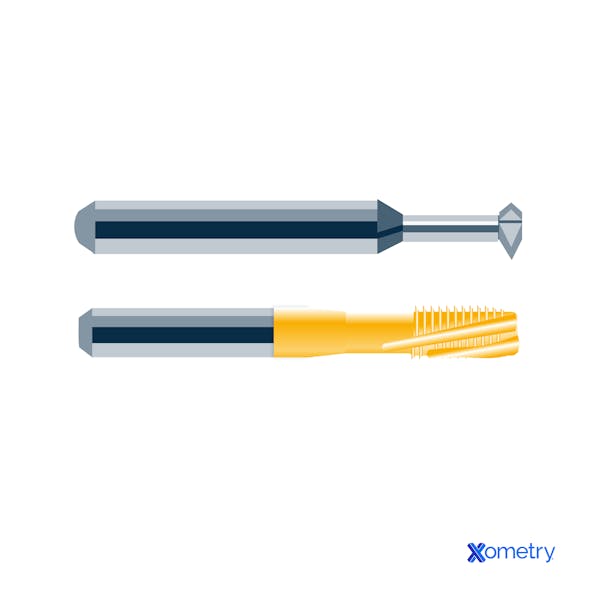

Thread mills are usually made from carbide which can last through thousands of holes before needing replacement, something that can be further extended when it’s kept clean and properly maintained. A thread mill looks a bit like an end mill but with a special thread pattern on the sides. There’s a shank for easy mounting on a tool holder, lots of teeth for cutting threads, and protective coatings to help them last longer. Below is a picture so you can get an idea of what a thread mill looks like.

This is just an example as their appearance will vary on their size, length, and design — and there’s a whole bunch to choose from.

Thread Milling—Pros and Cons

With thread milling, you have very accurate control over the size and fit of the threads you want to make. A single tool can make all different sizes and types of threads, even in tough materials like titanium or stainless steel, and it can make custom threads without you needing to splash out on custom taps. You also won’t need another tool to adjust the thread’s size if need be. It offers a high level of accuracy, and can make both interior and exterior threads, and both right- and left-handed ones.

On the flip side, thread milling requires quite specialized machinery with a high spindle speed (up to 60,000 RPM), and this could be quite the investment. Also, for very tiny threads (like those you’d find in watches or some medical devices), thread milling might not be the best option—the tools and process just aren’t ideal for the superfine precision needed for those tiny threads.

What is Tapping?

Tapping is another way to create threads but mainly inside a hole. It involves using a tool called a “tap,” which basically looks like your average screw with grooves, and it works almost like a standard drill. The tap is turned into a hole, and it cuts threads as it goes. It’s a fairly straightforward process that can either be done by hand or with a machine and can be used to make threads in aluminum or steel.

In tapping, a hole that's just the right size for the tap is drilled — it needs to be big enough for the tap to fit but small enough to make room for cutting the threads. After drilling, the tap is lined up with the hole, and some lubricant is added to help reduce friction and heat. Then, the tap is carefully turned into the hole, cutting the threads as it goes. The direction has to sometimes be reversed to clear out the chips created. Once the threads are cut, you’ll need to clean up any leftover chips or lubricant.

A tap looks kind of like a screw or bolt and has groves with sharp edges all the way down its sides that remove the chips from metal to make threads. They’re held in place by a collet, chuck, or other type of tool holder and then moved toward the material. Here’s an example of what a tap looks like.

Pros and Cons of Tapping

Tapping is a speedy process, especially if you’re looking to make lots of threads in a short amount of time. It can make deep threads in tough materials like steel and is the way to go if you need to make very small threads.

However, if you want to make different hole sizes with tapping, you’ll need many tools on hand. Also, once the thread is cut, it’s hard to change its size. Tapping is also not suitable for making external threads, although it’s great for internal ones.

In the table below, you’ll find a more analytical explanation of their exact differences in all the important categories.

| Factors | Thread Milling | Tapping |

|---|---|---|

Factors Life span | Thread Milling Long-lasting (thousands of holes), especially when made from durable materials like carbide | Tapping Made from high-speed steel which can wear out faster, particularly when used in tough materials, lasts a few hundred holes |

Factors Milling | Thread Milling Both internal and external threads | Tapping Mainly internal threads |

Factors Flexibility | Thread Milling High — you can adjust the thread size through programming | Tapping Lower — Tapping is fixed to the size of the tap |

Factors Accuracy | Thread Milling High, offers more precise control over thread dimensions | Tapping Less accurate than thread milling — any slight misalignment or material inconsistencies can affect the accuracy |

Factors Thread size | Thread Milling No size limitation | Tapping Best for very small threads in standard sizes, struggles with large threads |

Factors Power | Thread Milling May need more power because of the complex movement and high speeds depending on the material and size of the thread | Tapping Requires less spindle power since it’s a straightforward cutting process |

Factors Thread quality | Thread Milling Produces higher quality threads with a better surface finish, especially in tough materials | Tapping Might not match the same quality or level of finish, especially in harder materials |

Factors Speed | Thread Milling Slower (i.e, 8–10 seconds for a 1/4"-20 thread) | Tapping Faster (i.e, 4–5 seconds for a 1/4"-20 thread) |

Factors Chips | Thread Milling Creates chips that are smaller and easier to manage | Tapping Sometimes creates longer, stringy chips that are harder to control |

Factors Applications | Thread Milling Custom and large threads (like pipe threads) and large holes, precision, thin-walled, asymmetric, or non-rotating parts, accurate threads with tight tolerances, right-hand and left-hand threads | Tapping More practical for small, standard threads, screws, bolts, and other parts for automotive, aerospace, electronics, medical, and construction |

Factors Materials | Thread Milling Aluminum, stainless steel, titanium, high-temperature alloys, plastics, and composites | Tapping Softer metals like aluminum, brass, and mild steel, can also be used on plastics |

Factors Cutting process | Thread Milling Carves out the threads by moving the tool in a spiral pattern | Tapping Cuts threads by following the shape of the tap |

Factors Internal threads process | Thread Milling A CNC machine guides the tool in a spiral, or corkscrew, pattern into the material | Tapping The tap has to match the thread size and shape, so it simply follows the hole's path to create threads |

Factors External threads process | Thread Milling A CNC machine guides the tool, moving it around the outside of the material | Tapping Not typically used for external threads |

Factors Cost | Thread Milling High initial investment, slower process but does last longer and does not need additional tools | Tapping Less expensive initially (taps are typically cheaper and the process faster) but may need more regular replacement, plus more than one is needed for different hole sizes |

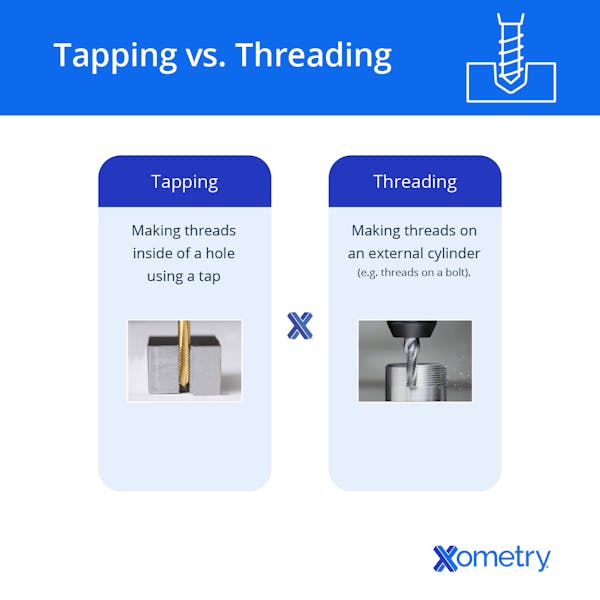

Tapping vs. Threading

| Needs ↓ | Thread Milling | Tapping |

|---|---|---|

Needs ↓ Speed | Tapping ✔ | |

Needs ↓ Tool life | Thread Milling ✔ | |

Needs ↓ Flexibility | Thread Milling ✔ | |

Needs ↓ Accuracy | Thread Milling ✔ | |

Needs ↓ Small/deep threads | Tapping ✔ | |

Needs ↓ Large/custom threads | Thread Milling ✔ | |

Needs ↓ Thread fit | Thread Milling ✔ | |

Needs ↓ Thread quality | Thread Milling ✔ | |

Needs ↓ Chip control | Thread Milling ✔ | |

Needs ↓ Cost | Thread Milling Cheaper for long-term use | Tapping Cheaper for short-term use |

Choosing Between Thread Milling and Tapping

Basically, if you need to make a lot of threads quickly, particularly small or deep ones, go for tapping, which is usually faster. It’s also more economical if you only need to make a few threads in standard sizes – so it’s good if you’re on a tight budget. If you need to adjust thread sizes, and work with various materials, large or custom threads, thread milling will be the method for you. It’s adaptable, and the tools also last much longer.

How Xometry Can Help

If you’ve decided which thread-making method is right for you, or if you are still stuck and want some help in the matter, our experts are on hand to help you out. Reach out to one of our reps or get a free, no-obligation quote for any of your manufacturing needs.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.