304 stainless steel is an American standard stainless steel grade that has a minimum of 66% iron, 17% chromium, and 8% nickel. To produce 304 stainless steel, all of the alloying metals that make up the steel are melted in an electric furnace and then cooled into billets. 304 stainless steel is known for its chemical resistance which is why it finds applications in kitchenware, food processing equipment, chemical processing equipment, and marine environments. In contrast to its outstanding corrosion resistance, the drawbacks of 304 stainless steel are it is difficult to machine and weld.

What Is 304 Stainless Steel?

304 stainless steel is an austenitic grade steel, and because of this 304 steel is generally nonmagnetic. It is also sometimes referred to as 18/8 steel due to its 18% chromium and 8% nickel content. Because 304 stainless steel is austenitic, it has a high-temperature phase with a face-centered cubic (FCC) structure.

Uses of 304 Stainless Steel

304 stainless steel is used in many kitchen applications including sinks, splashbacks, saucepans, cutlery, and flatware. 304 can also find use in architectural paneling, sanitaryware, tubing, breweries, dairies, food and pharmaceutical production equipment, and springs, nuts, bolts, and washers.

How Is 304 Stainless Steel Made?

304 stainless steel is made by measuring the required amounts of each element such as: iron, chromium, and nickel. These metals and coke are added to a furnace (usually electric), which heats them to their melting point in a process that can take 12 hours. Once melted, the carbon must be removed using either a vacuum or oxygen decarburization (VOD). The amount of carbon removed will affect the hardness and tensile strength of the material. Before cooling, the steel will be stirred to ensure that the elements are uniformly mixed. As the metal is cooled into billets, it may be hot rolled while still above its crystallization temperature to form the steel into shape. If precise dimensions are required, the steel may be cooled and rolled below its crystallization temperature. Once cooled, the steel may be heat treated to relieve its internal stresses. Finally, the stainless steel will be cut to its final shape and surface-finished which will depend on the application of the steel but may include grinding.

Chemical Composition of 304 Stainless Steel

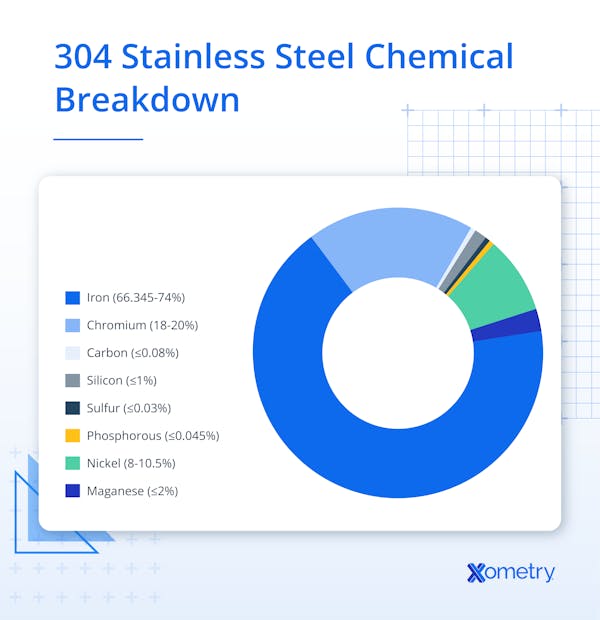

The main element of steel is iron. It is present in 304 stainless steel at a level between 66% and 75%. The iron content of 304 stainless steel is much lower than other steels due to its high content of alloying elements. 304 stainless steel also has a chromium content of 17–20% and a nickel content of 8–11%. The full composition of 304 stainless steel is shown in donut chart below:

Carbon Content of 304 Stainless Steel

The maximum carbon content of 304 stainless steel is 0.08%. An increase in carbon content would increase the hardness, strength, and weldability of the steel. However, it would also decrease ductility and responsiveness to heat treatments.

Properties of 304 Stainless Steel

Table 2 below lists the properties of 304 stainless steel:

| Property | Value |

|---|---|

Property Density | Value 0.286 lb/in3 |

Property Yield Strength | Value 31,200 psi |

Property Hardness (Rockwell) | Value 70 |

Property Magnetism | Value Nonmagnetic (Austenitic) |

Thermal Properties of 304 Stainless Steel

The melting point of 304 stainless steel is between 2,550ºF and 2,650ºF depending on the exact composition. 304 steel also has a thermal conductivity of 112 Btu-in/hr-ft2-ºF, a specific heat capacity of 0.12 Btu/lb-ºF, and a rate of linear thermal expansion of 9.61 µin/inºF.

Common Forms of 304 Stainless Steel Material

Some common forms of 304 stainless steel are listed below:

Sheet

304 stainless steel can be found in sheet metal form between the thicknesses of 0.018” and 0.250”. Sheet metal stainless steel is usually used to make bodywork and panels for various machinery. 304 stainless steel sheet metal can be used to create grills, sinks, pots, pans, and cookers.

Bar

The bar form of 304 stainless steel can come in different geometries including circular and tubular. The bar form of 304 steel is used for structural applications in which corrosion resistance is of high importance.

Plate

Any plate of 304 stainless steel will be of a thickness greater than 0.250”. Plates, like sheet steel, can find application in the food industry for food processing equipment. 304 steel can also be used for architectural cladding.

Hot Rolled

The hot rolling of 304 stainless steel should be carried out at temperatures between 2,100 ºF and 2,300 ºF. By hot rolling 304 steel, a strain is created on the metal microstructure which causes dislocations. The increase in dislocation density strain hardens the steel creating a stronger and harder steel.

Annealed

The annealed form of 304 stainless steel has the lowest strength but also the highest ductility of the different forms of 304 steel. Annealing should be used after cold working to stop 304 stainless steel from cracking as the steel suffers from work hardening. The annealing of 304 steel should be carried out at temperatures between 1,850 ºF and 2,048 ºF. The crystal structure can grow in a way that reduces internal stresses by heating the steel to just below its melting point and then cooling it slowly. The annealing process will remove impurities and reduce the brittleness and hardness of the steel.

Cold-Drawn

The cold drawing process has a very similar effect to the cold and hot rolling process which results in the increase of dislocation density, making the steel harder and stronger. However, the cold-drawn process hardens the steel faster making the steel much harder and stronger than hot rolling. However, since the steel work hardens, annealing is required to prevent it from cracking. Cold drawing the steel makes a more dimensionally accurate product as there is no thermal expansion and contraction as there is with hot rolling.

Equivalent Grades of 304 Stainless Steel

Table 3, showing the equivalent forms of 304 steel is given below. Note that some chemical compositions may not be an exact match but are the nearest equivalent:

| Country | Equivalent Grade |

|---|---|

Country EU | Equivalent Grade X5CrNi18-10 |

Country USA | Equivalent Grade 304304N |

Country Germany | Equivalent Grade X5CrNi18-9 |

Country Japan | Equivalent Grade SUS304 |

Country France | Equivalent Grade X5CrNi18-10 |

Country England | Equivalent Grade 304S15; 304S31 |

Country Russia | Equivalent Grade 08KH18N10 |

Country China | Equivalent Grade 0H18N9 |

Country Italy | Equivalent Grade X5CrNi18-10 |

Advantages of Using 304 Stainless Steel

The biggest advantage of using 304 stainless steel is its corrosion resistance. This makes it ideal for use in environments including chemical processing, food processing, and shipbuilding. Other advantages of using 304 stainless steel are listed below:

- It is nonmagnetic.

- Easy to clean.

- It is durable.

- Good impact resistance.

Disadvantages of Using 304 Stainless Steel

One of the drawbacks of using 304 stainless steel is that it is susceptible to stress corrosion cracking. This occurs when cracks form and grow in a corrosive environment. This can lead to sudden failure of a material. 304 should be properly monitored in a corrosive environment to overcome this. Some of the other disadvantages of using 304 stainless steel are listed below:

- Less strong than other steels.

- Less heat resistant than other steels.

- Challenging to weld.

- Expensive due to alloying elements.

304 Stainless Steel vs. 316 Stainless Steel

304 and 316 are two of the most common stainless steels and are both very hard to distinguish physically. However, they can be identified as they do have slightly different chemical compositions. For example, 316 has 2% molybdenum which makes it more corrosion-resistant than 304. This also makes 316 more expensive. For more information, see our guide on stainless steel grade 316.

304 Stainless Steel vs. 430 Stainless Steel?

One major difference between 304 and 430 steel is that 304 steel is more expensive. This is due to the 8% nickel content of 304 steel compared to the lack of any nickel in 430 steel. The presence of nickel in 304 also makes it more corrosion-resistant. The other difference between 304 and 430 steel is that 304 steel is austenitic which means it is nonmagnetic. On the other hand, 430 is ferritic-grade steel which makes it very magnetic. These properties must be considered to choose the right steel for an application.

304 Stainless Steel vs. 18/10 Stainless Steel

18/10 gets its name from having 18% chromium content and 10% nickel content. 18/10 steel is also known as type 304 steel. Type 304 steel should not be confused with 304-grade steel which is of a different composition. The main difference between 18/10 and 304 steel is that 304 steel forms a protective layer on its surface which prevents corrosion. 18/10 does not have such as layer and is more susceptible to corrosion. The difference in the surface composition of 18/10 and 304 steel means that 18/10 has a more shiny surface finish which means it is used for more decorative purposes than 304 steel.

To learn more about 304 stainless steel and how it can be applied to your project, contact a Xometry representative or check out our quoting tool.

Summary

This article presented 304 stainless steel, explained what it is, and discussed its various applications. To learn more about 304 stainless steel, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.